Page 10

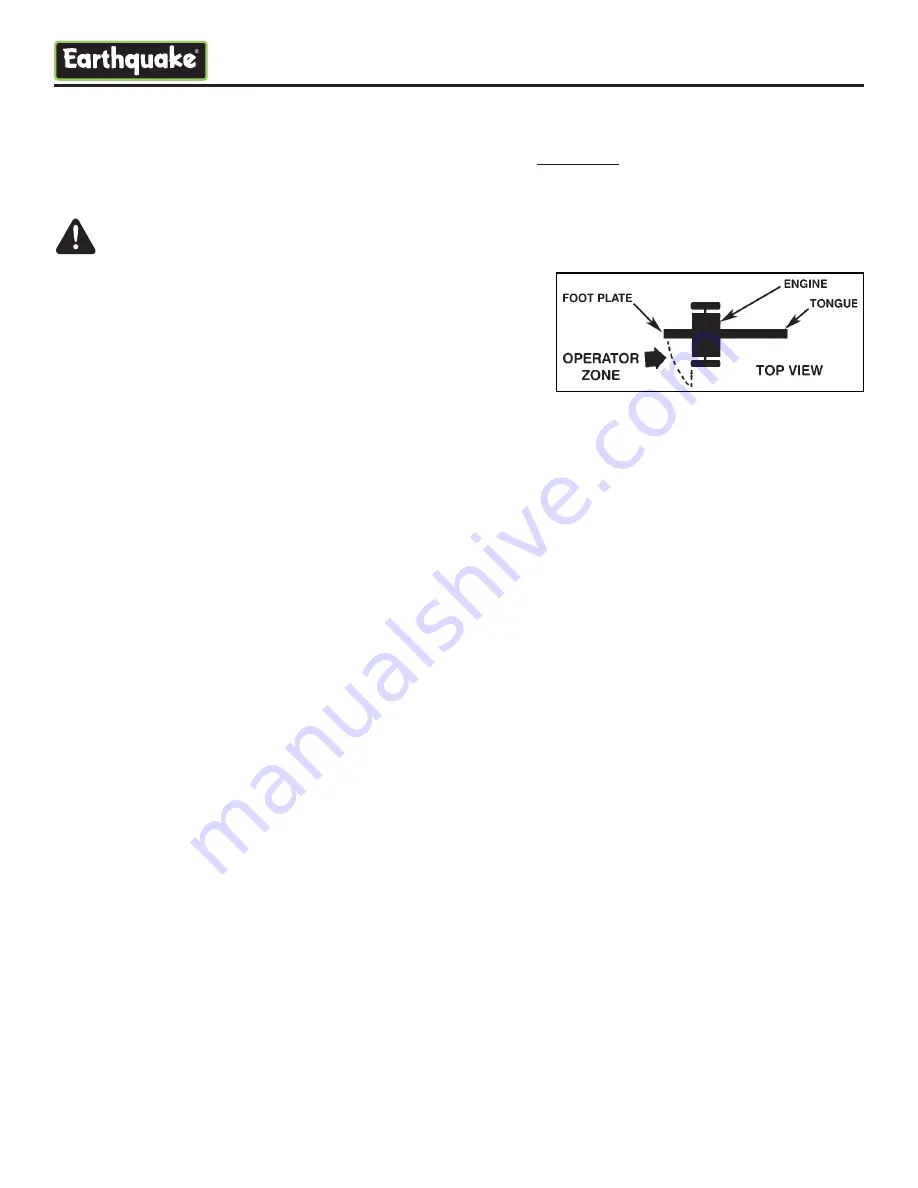

LOG SPLITTER OPERATING INSTRUCTIONS

STARTING

IMPORTANT: The engine and hydraulic reservoir are shipped without oil. See the Engine Operator’s

Manual packed with your log splitter for the type of crankcase oil, fuel, etc. The engine manufacturer

recommends lead-free gasoline only.

CAUTION: DO NOT START OR RUN THE ENGINE WITHOUT OIL IN THE HYDRAULIC

RESERVOIR AND ENGINE.

1. The hydraulic reservoir should be filled with an SAE 30 hydraulic

oil (if temperature will be above 50 degrees when operating unit)

and SAE 20 hydraulic oil (if temperature will be between 32

degrees and 50 degrees). If hydraulic oil is difficult to obtain,

automatic transmission fluid can be substituted and should be

used instead of hydraulic oil when temperatures are below 32

degrees F. Use only clean oil and take care to prevent dirt from

entering the hydraulic reservoir.

ENGINE OIL RECOMMENDATIONS

1. For temperatures above 40 degrees F use an SAE 30W oil. Using multigrade oil may increase oil

consumption. Using SAE 30W oil below 40 degrees F will result in hard starting and possible engine bore

damage. For temperatures below 40 degrees F use an SAE 10W-30 or SAE 5W-30 oil. Oil capacity is about

1-1/2 quarts (48 ounces or 1.4 liters). Refer to Engine Operator’s Manual for further information.

DIRECTIONS FOR FILLING HYDRAULIC SYSTEM

1. Fill the hydraulic reservoir with at least three gallons of hydraulic fluid. After the hydraulic reservoir and the

engine crankcase are filled with oil, start the engine. The hydraulic pump should prime itself. With the engine

running, move the hydraulic valve lever toward the wedge. This will cause the cylinder to extend and expel

air. When the cylinder is fully extended, retract it. Repeat this procedure several times. An erratic movement

of the cylinder indicates that there is still air in the system.

NOTE: If the reservoir is overfilled, it will tend to expel oil from the breather cap when the cylinder is

retracted.

STARTING INSTRUCTIONS

1. Move the throttle lever to

“FAST”

. Always operate the engine with throttle lever in the

“FAST”

position.

2. Move choke control lever to

“CHOKE”

position.

3. Grasp rope handle and pull slowly until resistance is felt. Then pull rapidly to start engine and avoid engine

kickback.

4. Allow the engine to warm up. If operating in warm weather, move the choke control lever toward

“RUN”

a

short distance at a time over several seconds. For cold weather operation do this procedure over several

minutes. Operate with choke lever in the

“RUN”

position.

5. To stop engine, move the throttle lever to the

“STOP”

position.

NOTE: The maximum governed speed on the engine is preset at the factory at 3600 RPM no load

speed. When splitting wood, the throttle should be set at the maximum setting to develop the

horsepower required for the pump.