Page 12

LOG SPLITTER OPERATING INSTRUCTIONS

MAINTENANCE

1. Consult the operating and maintenance instructions of the Engine Operator’s Manual for engine care and

maintenance.

2. Always check the oil level of the hydraulic reservoir before operation. Operating the log splitter without an

adequate oil supply will cause severe damage to the hydraulic pump.

3. Change the oil filter after the first 25 hours of operation. Thereafter, change the oil filter every 100 hours or

seasonally, whichever comes first.

4. If the wedge becomes dull or nicked, it can be removed and sharpened. While the log splitter is in the

horizontal position, remove the 1/2” x 3-1/2” bolt (4362) that connects the wedge to the hydraulic cylinder.

Carefully rotate the hydraulic cylinder, take special care not to damage the control valve. The wedge can

now be removed and sharpened.

5. Refer to the Repair and Maintenance Safety section of this manual.

6. All replacement parts must meet manufacturer’s specifications.

7. Check air pressure of tires before each use. Maintain pressure between 20 psi and 30 psi.

8. Grease wheel bearings annually.

STORAGE

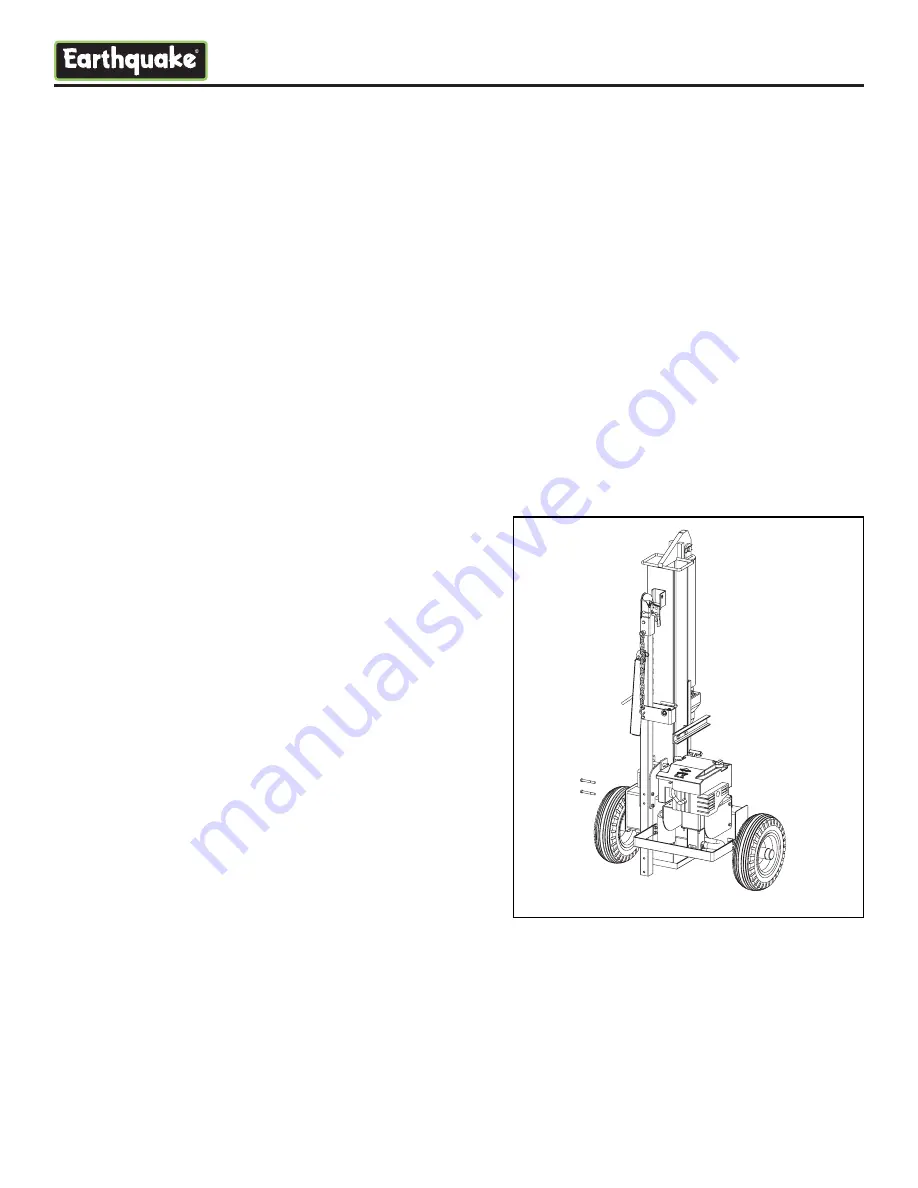

1. Rotate the beam to the vertical position after the log splitter

has been moved to its storage location. Ensure that the

locking pin for the vertical position has been fully engaged.

2. While a second person balances the beam vertically, unbolt

the tongue from the reservoir. Save the nuts and bolts.

Rotate the tongue 90 degrees and stand it on the end that

was previously bolted the reservoir. Re-install the two nuts

and bolts that were removed in Step 1.

Refer to Figure 9.

3. To return the unit to its functional state, follow the Steps in

reverse order.

Figure 9