Page 2

One Year Limited Warranty

The Ardisam, Inc., Manufacturing Company warrants this Earthquake

®

Log Splitter to be free from

defects in material or workmanship for the normal service life of the product not to exceed

12 consecutive months from the date of purchase. The cylinder, valve, pump and other hydraulic

components are guaranteed for two (2) years from the date of purchase. The engine is covered under a

separate warranty provided by the manufacturer and is enclosed with the owner/operator’s manual.

Conditions of this warranty include:

What is covered under warranty:

Ardisam, Inc. will repair or replace any part that in our judgement is found to be defective in material or

workmanship during the warranty period stated above after delivery of the log splitter to the original

purchaser.

What is not covered under warranty:

This warranty applies only to products which

have not

been subjected to negligent use, misuse,

alteration, accident or if repairs have been made by anyone outside our factory. This warranty applies

only to the original purchaser, and is not transferrable.

How to obtain service:

Return the product to us at the address below with transportation charges prepaid.

This warranty supersedes all other warranties either expressed or implied and all other obligations or

liabilities on our part. Ardisam, Inc., does not assume, and does not authorize any other person to

assume for us, any liability in connection with the sale of our products. This guarantee is void unless

warranty card is properly filled out and returned to Ardisam, Inc., Cumberland, Wisconsin, at time of

purchase.

THANK YOU ÷ ÷ ÷

for purchasing an Earthquake

®

Log Splitter

from Ardisam, Inc. We guarantee that this log

splitter conforms to applicable North American

safety standards, and have worked to ensure

that it meets high standards for usability and

durability. With proper care, it will provide you

with many years of service. Please take the

time to read this booklet carefully to learn how

to correctly assemble and operate your log

splitter. Congratulations on your investment in

quality.

WARRANTY

ARDISAM

Ardisam, Inc.

1690 Elm Street, Cumberland, WI 54829

Phone (715) 822-2415 Fax (715) 822-4180

Email info@ardisam.com

www.ardisam.com

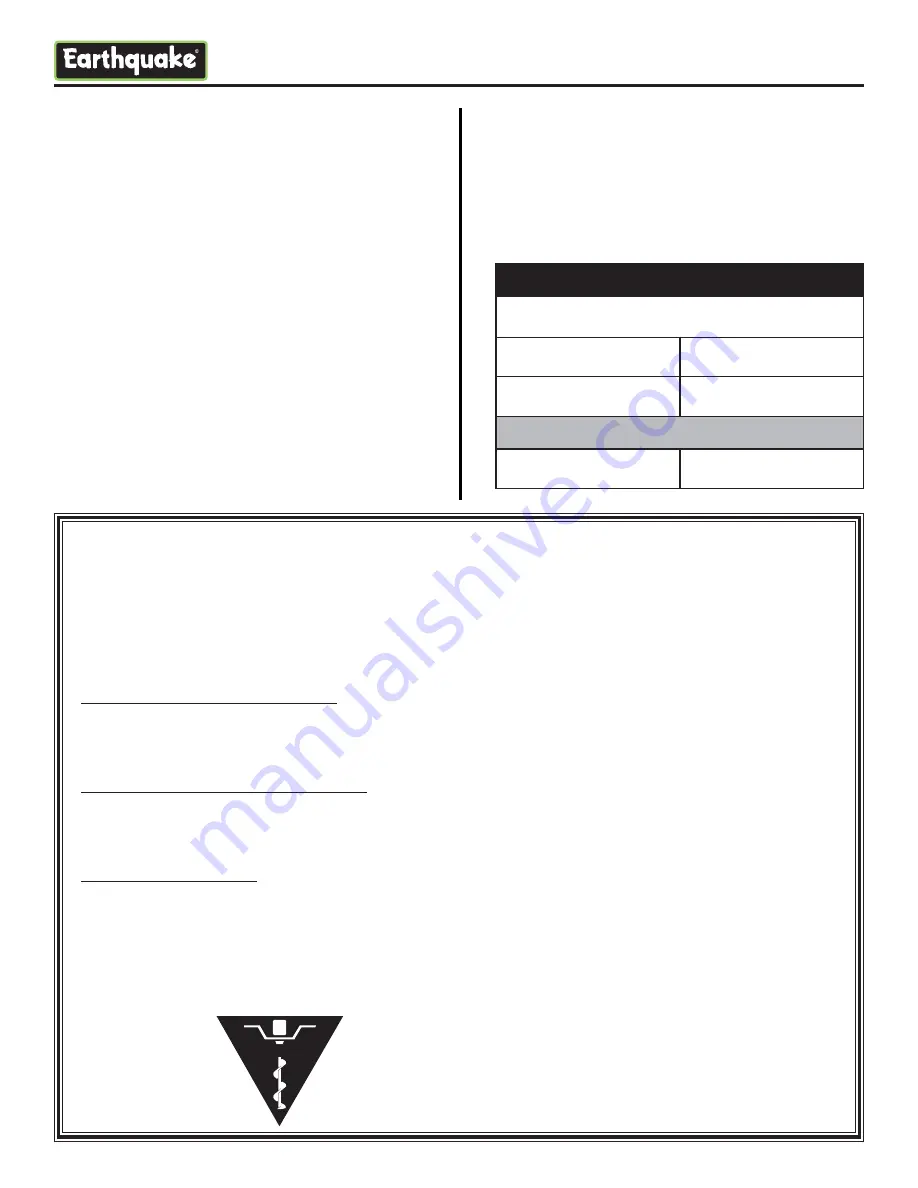

LOG SPLITTER REFERENCE DATA

Model Description/Number

M/N (Manufacturer's Number)

S/N (Serial Number)

Dealer Name

Date Purchased

ENGINE REFERENCE DATA

Engine Make/Model

Engine ID/Serial Number

MODEL IDENTIFICATION

Record your model number, manufacturer number and

serial number in the space provided for easy reference.

The model and manufacturer numbers can be found on

the inside leg of the engine mount plate. Refer to the

Engine Owner’s Manual for location of engine serial

number.