Page 3

SAFETY AND MAINTENANCE

SAFETY INSTRUCTIONS

·

Before operating this log splitter, carefully

read this manual and follow all instructions

.

•

Do not

allow anyone to operate your log splitter

who has not read this manual.

•

Never

operate your log splitter for any other

purpose than splitting wood.

•

Do not

operate the log splitter under the

influence of alcohol, drugs or medication.

•

Never

allow children to operate the log splitter.

Keep small children away from the work area. If a

second person is assisting in loading logs,

never

activate the log splitter until the helper is clear of

the work area.

PREPARATION

•

Dress appropriately when operating the log

splitter.

Always

wear safety footwear.

Never

wear

sandals, sneakers, or open shoes, and

never

operate the log splitter with bare feet.

Do not

wear

loose clothing or jewelry that might get caught in

moving parts.

•

Always

wear safety glasses while operating your

log splitter. Wear proper head gear to keep hair

away from moving parts.

•

Always

wear a protective hearing device.

•

If you wear gloves,

be sure

they are tight fitting

without loose cuffs or draw strings.

•

Both ends of each log should be cut as square as

possible to help prevent the log from sliding out of

the splitter during operation.

•

Handle

fuel with care; it is highly flammable.

a.

Use

an approved fuel container.

b.

Never

add fuel to a running engine or hot engine.

c.

Fill

fuel tank outdoors with extreme care.

Never

fill fuel tank indoors.

d.

Replace

gasoline cap securely and clean up

spilled fuel before restarting.

•

Never

attempt to make any adjustments to the log

splitter while the engine is running.

OPERATING PROCEDURE

•

Never

operate the log splitter without guards in

place.

•

Only

operate the log splitter from the operator zone.

•

Know how to stop the unit and disengage the

controls.

•

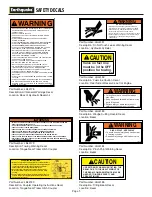

Never

place hands and/or feet between log and

splitting wedge or between log and ram during

forward or reverse stroke.

•

Do not

step over or straddle the log splitter when

the engine is running.

Never

reach or bend over

the log splitter to pick up a log.

•

Never

try to split two logs on top of each other at

the same time.

•

Never

allow one person to operate the valve while

another is positioning the log.

•

Never

attempt to load your log splitter when the

ram is in motion.

•

Only

use your hand to operate the control lever.

Never

use your foot or a rope or any other

extension device.

•

Always

keep fingers away from any cracks that

open in the log during splitting operation.

•

Never

move the log splitter while the engine is

running.

•

Never

leave your log splitter unattended with the

engine running. Shut off the engine if you are

leaving your splitter--even for a short period of

time.

•

Do not

run the engine in an enclosed area.

Exhaust gases contain carbon monoxide. This

odorless gas can be deadly when inhaled.

•

Do not

operate your log splitter on slippery, wet,

muddy, or icy surfaces.

•

Only

operate your log splitter on level ground and

not on a hillside.

•

Never

attempt to move the log splitter over hilly or

uneven terrain without a tow vehicle or adequate

help.

•

Always

block wheels to prevent movement of log

splitter while in operation.

•

Keep

work area clean. Immediately remove split

wood around your log splitter so that you don’t

stumble over it.

•

Always

use your log splitter in daylight.