Page 5

SAFETY DECALS

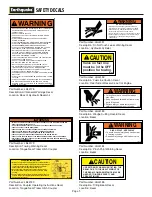

Part Number: LBL4178

Description: All General Warnings Decal

Location: Back of Hydraulic Reservoir

Part Number: LBL4179

Description: Towing Warning Decal

Location: Tongue Near Trailer Hitch Coupler

Part Number: LBL4180

Description: Coupler Operating Instructions Decal

Location: Tongue Near Trailer Hitch Coupler

Part Number: LBL4183

Description: Wedge Cutting Hazard Decal

Location: Beam

Part Number: LBL4184

Description: Pinch Point Warning Decal

Location: Beam

Part Number: LBL4185

Description: Tilting Beam Decal

Location: Beam

Part Number: LBL4182

Description: Fuel Line Caution Decal

Location: Rear Side of Reservoir, Left of Engine

Part Number: LBL4181

Description: Do Not Touch Leaks Warning Decal

Location: Hydraulic Cylinder

•

•

•

•

•

•

•

•

•

FAILURE TO FOLLOW THESE RULES CAN CAUSE TRAILER TO DETACH WHILE TOWING AND MAY

RESULT IN SERIOUS INJURY OR DEATH.

DO NOT EXCEED WEIGHT CAPACITY OF BALL OR LOAD LIMITS STAMPED ON COUPLER.

ALWAYS USE SAFETY CHAINS WHEN TOWING.

ALWAYS CHECK THAT THE COUPLER HANDLE IS LOCKED BEFORE TOWING.

ALWAYS USE THE CORRECT BALL SIZE THAT IS STAMPED ON COUPLER.

ALWAYS ADJUST COUPLER LOCKING PRESSURE ON BALL BEFORE USE.

CHECK COUPLER TIGHTNESS BEFORE TOWING AND AFTER TOWING 50 MILES.

ALWAYS CHECK COUPLER AND BALL FOR DAMAGE BEFORE TOWING. REPLACE IF DAMAGED.

AVOID SHARP TURNS AND STEEP VERTICAL ANGLES WHEN TOWING TO PREVENT DAMAGE TO

COUPLER OR ITS COMPONENTS.

WARNING

!

LBL4179

OPERATING INSTRUCTIONS

1) Before using, adjust coupler locking pressure on ball. Put handle in

locked position with ball in coupler. Tighten locknut against tension

spring so that coupler is firmly on ball. The proper adjustment

allows handle to be released with moderate pressure.

2) Pull up on coupler handle to open and place coupler over ball.

When ball is seated in ball socket pull back on handle to locked

position.

3) Check to make sure the coupler is tight on the ball after towing for

50 miles. Always check for tightness before towing and make sure

handle is in locked position.

LBL4180

DO NOT TOUCH LEAKS

•

•

•

•

High Pressure fluid easily penetrates skin and

infects blood - causing injury, gangrene or death.

Seek emergency medical help at once if injured,

liquid needs to be removed from tissue.

Do not reach for or use any skin to check for leaks.

Relieve hydraulic pressure or accumulator before

maintenance or before loosening hydraulic

components.

WARNING

!

LBL4181

Valve on fuel line

must be in the OFF

position for towing.

CAUTION

!

LBL4182

•

•

•

Cutting hazard at wood splitter wedge –

stay clear.

Keep hands and limbs away from moving

parts & log ends.

Serious injury or death could result if

safety precautions are not followed.

WARNING

!

LBL4183

WARNING

!

PINCH POINT - KEEP AWAY

•

•

To avoid serious injury, keep hands clear

of moving cylinder.

Speeds may change with loads or valve

functions.

LBL4184

USE EXTREME CARE WHEN TILTING THE

BEAM. DUE TO THE HEAVY WEIGHT OF

THE BEAM, SOME ASSISTANCE MAY BE

NEEDED TO INSURE SAFETY AND

PREVENT INJURY.

CAUTION

!

LBL4185

WARNING

!

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

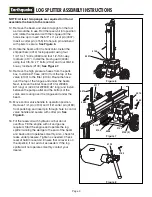

READ AND UNDERSTAND OPERATOR'S MANUAL THOROUGHLY

BEFORE OPERATION. FAILURE TO DO SO MAY RESULT IN

SERIOUS INJURY.

KEEP ALL SHIELDS IN PLACE.

KEEP HANDS, FEET AND CLOTHING AWAY FROM POWER-

DRIVEN PARTS.

ALWAYS WEAR SAFETY GLASSES AND SAFETY SHOES

DURING OPERATION.

ALWAYS OPERATE OUT-OF-DOORS WITH GOOD VENTILATION.

ALWAYS STOP ENGINE AND REMOVE SPARK PLUG WIRE

BEFORE PERFORMING MAINTENANCE OPERATIONS.

ALWAYS SHUT OFF ENGINE WHEN LEAVING LOG SPLITTER

UNATTENDED, EVEN FOR A SHORT PERIOD OF TIME.

ONLY ONE PERSON SHOULD LOAD AND OPERATE THE LOG

SPLITTER. KEEP ALL OTHERS CLEAR DURING OPEATION.

NEVER ALLOW ONE PERSON TO OPERATE VALVE WHILE

ANOTHER IS POSITIONING THE LOG.

ALWAYS POSITION LOG WITH HANDS ON THE SIDES OF LOG.

KEEP HANDS CLEAR OF ENDS.

KEEP ALL CHILDREN AWAY FROM THE LOG SPLITTER.

DO NOT STEP OVER THE LOG SPLITTER.

ONLY USE HANDS TO OPERATE THE CONTROL VALVE.

DO NOT OPERATE THE LOG SPLITTER WHILE UNDER THE

INFLUENCE OF ALCOHOL, DRUGS OR MEDICATION.

ALWAYS OPERATE THE LOG SPLITTER ON LEVEL, DRY, NON-

SLIPPERY SURFACES. KEEP OFF SLOPES.

KEEP WORK AREA CLEAR OF SPLIT WOOD, DEBRIS OR OTHER

OBSTACLES.

ALWAYS STAY IN THE OPERATOR ZONE WHEN USING THE LOG

SPLITTER.

ALWAYS SPLIT WOOD IN THE DIRECTION OF THE GRAIN ONLY.

DO NOT ADD GASOLINE WHILE THE ENGINE IS HOT OR

RUNNING. ALLOW ALL SPILLED GAS TO EVAPORATE BEFORE

USING LOG SPLITTER.

LBL4178