Assembly and Operation Instructions

P2170_M52164_Rev_May2020_compressed

PAGE 7

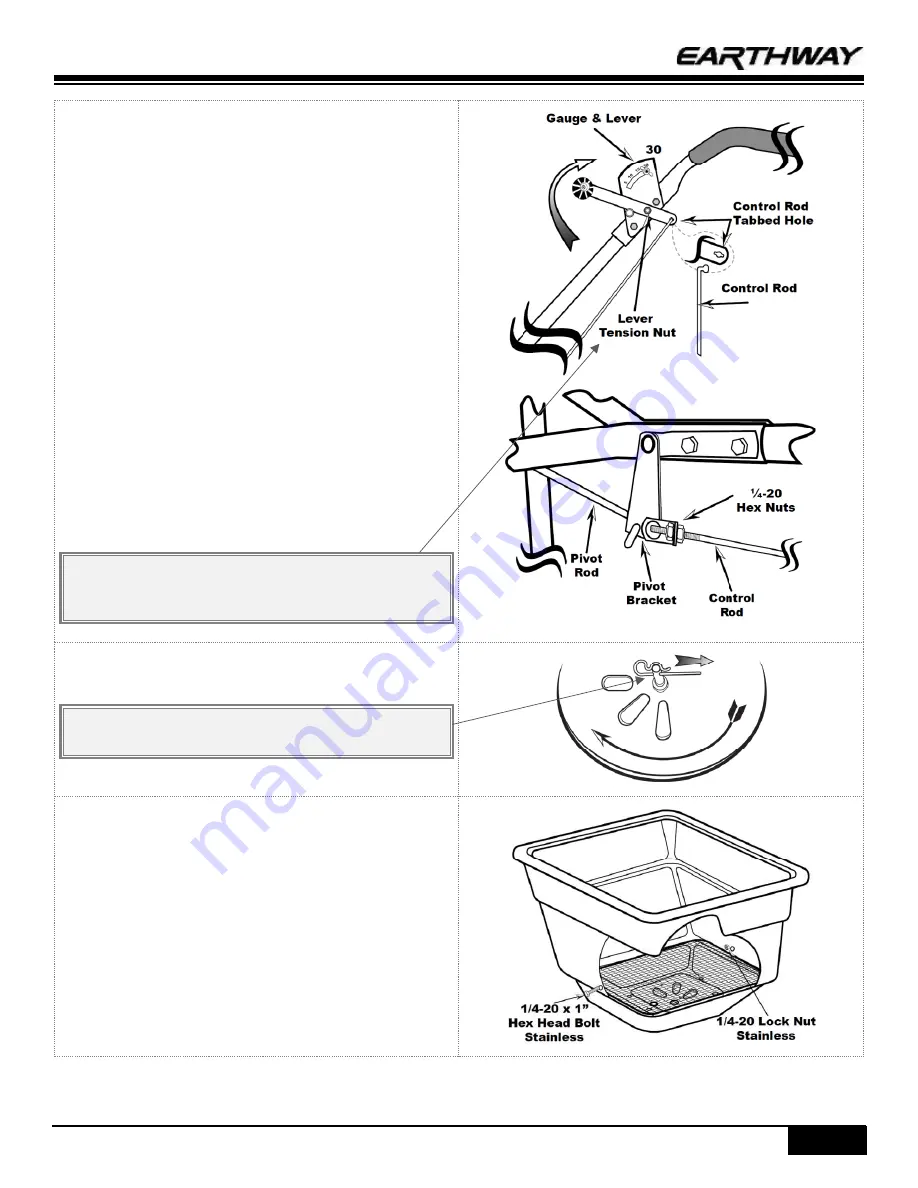

Step 15:

Install flattened end of control rod in to lever

on gauge as shown. Turn to lock in place. Next push lever

forward to setting “0”. Align control rod with hole in

pivot bracket, pull lever backward to insert control rod

through hole in pivot bracket. Now install ¼-20 Hex nut

on to control rod.

Step 16:

Pull lever back to setting “30” as shown. Next

push pivot & bracket forward so that the shut off plate in

the hopper is in the full open position.

REMEMBER

SETTING “30” ON THE FLOW CONTROL LEVER MUST

PLACE THE SHUT-OFF PLATE IN THE FULL OPEN

POSITION TO BE PROPERLY CALIBRATED

. Now tighten

the nuts against the pivot bracket to prevent change in

calibration.

NOTE

: Tension on the flow control lever may be

adjusted by tightening or loosening the tension nut as

shown.

Step 17:

Insert agitator to pinion shaft on inside of

hopper.

Note

: the position of flat side of the agitator. This pin

should be installed as shown.

Step 18:

Install debris screen into hopper, then insert ¼-

20 x 1

″

Stainless Steel Hex Bolt thru the hole in the side

wall of the hopper. Secure with Stainless Steel lock nut.

TIGHTEN WITH HAND TOOLS ONLY

.