Using the EV-N-SPRED

®

Dual Port

PRO

Adjustable

Shut-Off System

The EV-N-SPRED

®

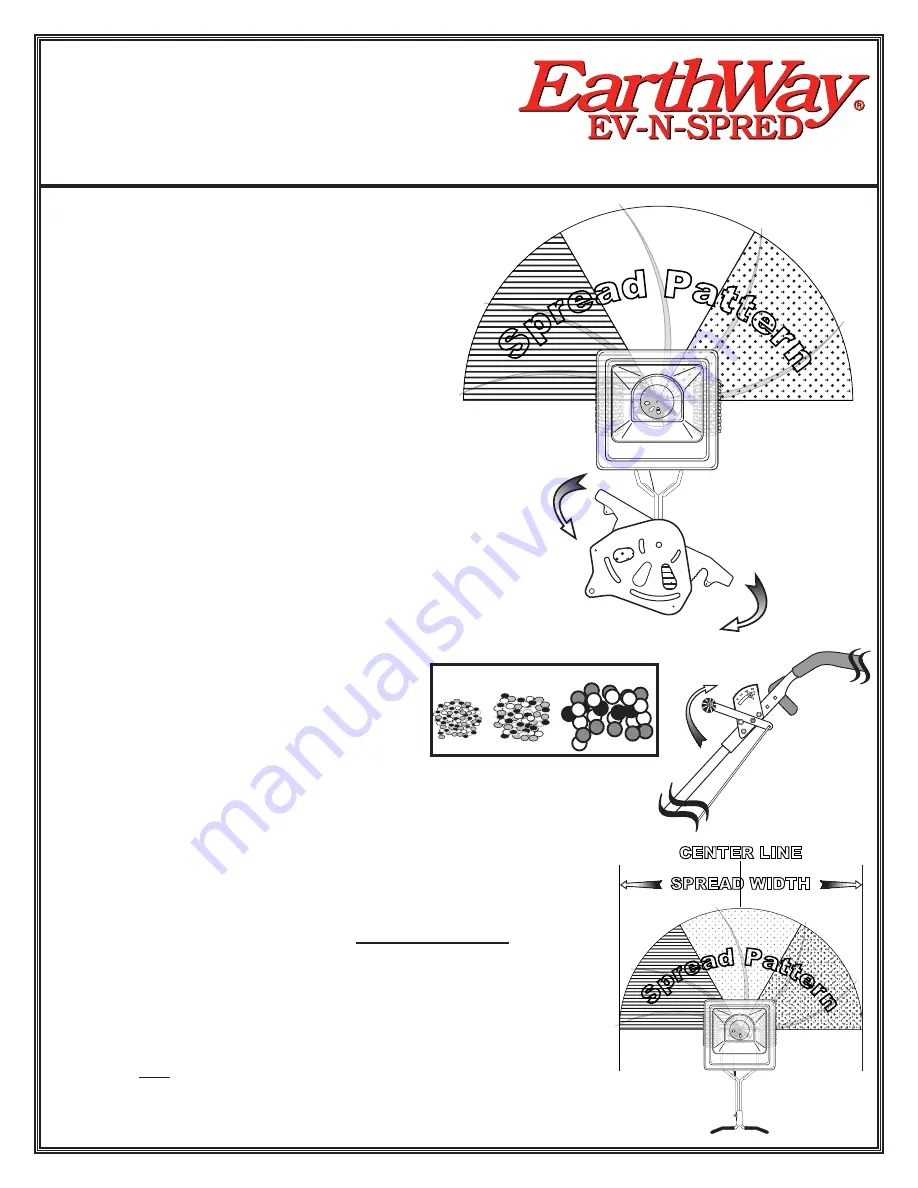

Dual Port PRO Adjustable Shut-Off System is

included on all professional models and allows the operator

to balance the spread pattern evenly across the full 180

o

spread width, regardless of the weight or size of granular

material. By closing either the right and or left side

throwing ports you can balance the spread pattern to

exacting precision without compromising spread width

or application rate.

Each EV-N-SPRED

®

Dual Port PRO Adjustable

Shut-Off System drop hole has a corresponding

1/3

rd

coverage area on the spread width of the spreader leaving a

feathered-edge for overlapping the spread path. The illustration to

the right shows each port and the corresponding

1/3

rd

coverage

area of the spread path. These ports can be adjusted to effectively

balance the spread pattern, giving equal amounts of material

across the full 180

o

spread pattern.

EV-N-SPRED

®

Dual Port PRO System Setup

Test all material prior to beginning your spreading job.

You will need

a 50’ measuring tape, a small scale to weigh the material, bucket or

container to hold the material for re-weighing, chalk or a line marking

device, and (7) low baking tins.

Using the EarthWay

®

Bag Calibrator

#77016 can greatly reduce the time needed for

determining the Setting Rates on any material but

is not mandatory to establish a setting rate.

1. Evaluate the material being spread by comparing

it to the following standard as a reference.

Large/Heavy

is the size of a BB (⅛ in / 3mm), spread width is 20 - 30 feet (7.6 -

9.1 meters

Medium/Mixed

(½ the size of a BB), spread width is 16 - 20 feet (4.8 - 7.6 meters)

Small/Fine

(the size of sand), spread width is 12 - 16 feet (3.7 - 4.8 meters)

2.

Add a small amount of the material into the spreader, enough to cover

the bottom (2-3 in / 5 - 7 cm) and begin to

test for spread width.

Set the stop on the gauge to #15 and push the spreader several feet /

meters at normal walking speed on a flat hard surface (where the material

will be visible), and OPEN the lever to the STOP while continuing to

walk for 3-4 paces, and

CLOSE the shut-off and STOP (don’t move the

spreader from that position). Measure the spread width and evaluate

the spread pattern for even distribution on either side of the spread width

center line.

TIP:

Typical spread width references are listed above.

The

spread width that you measure is used to calculate the actual

Setting

Rate

for the material.

Sp

rea

d Patte

rn

Adjustable Throwing Ports

with 8 repeatable settings

to balance the left or right

spread pattern to

the center.

Sp

rea

d Patte

rn

SPREAD WIDTH

Gauge & Lever

15

FINE

MEDIUM

LARGE