How to use the S15 Sprayer

~ continued

Technical spray information and how to ensure accuracy

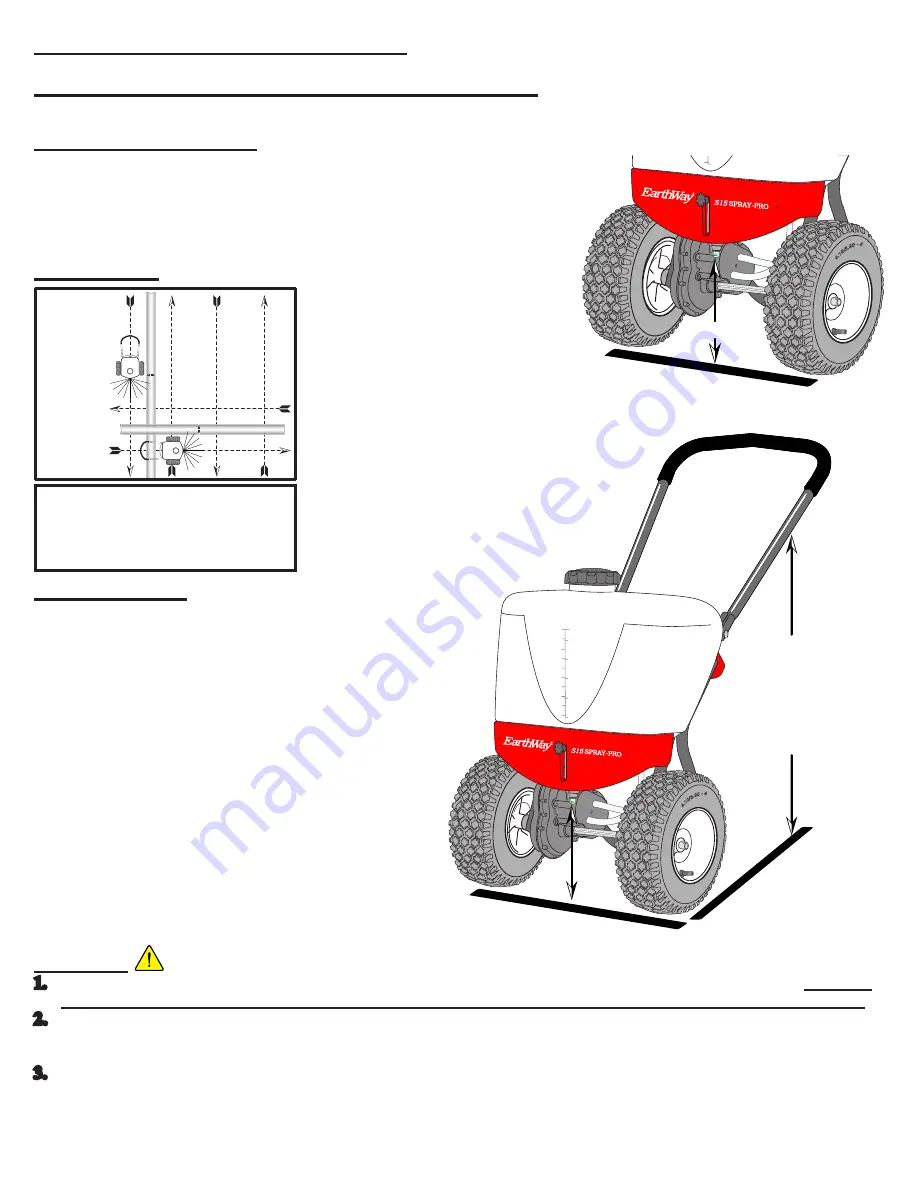

The S15 SPRAY-PRO has an adjustable height nozzle that offers spray widths from approximately 3 feet/.9 meters to 5 feet / 1.5 meters.

Spray Width Adjustment

You can adjust the spray width of the S15, which will change the application coverage, by

moving the Adjustable DCV holder up or down. To use, loosen the knob located on the front

of the skirt, and slide the DCV & Nozzle assembly up/down to the desired spray width or to a

position indicated on the Application Chart on the previous page, then tighten knob. There

are indices molded into the DCV Holder for easy repeatability.

The SPRAY-PRO Teejet TF nozzles are

designed to “feather” at the edges to allow

the second pass to “feather in,” and so

provide uniform coverage. The area of

“feather” or overlap, is approximately 15%

of the spray width at the edges, for a total of

30% over the two edges/ends of the spray

pattern. To maximize uniform coverage the next

pass should overlap the prior to allow for the

15% “feather” or overlap.

Ensure accuracy

It is important that the S15 SPRAY-PRO sprayer has a minimum of

1-gallon/4-litres of liquid in the tank at all time, and is pushed in a manner

that keeps the spray head parallel to the ground at all times, so that the

spray nozzle is constantly kept at the same correct height. Keeping the

height of the nozzle constantly parallel to the ground ensures the nozzle

will spray to its stipulated spray application cover. If the sprayer is pushed

at a downward angle and the nozzle tip is nearer to the ground, the spray

width will be reduced and over application will occur. In the reverse

situation of the spray nozzle height being increased by pushing the

sprayer at an upward angle the nozzle fan will be wider, the spray

width will become inaccurate, and under application will likely

occur. To ensure spray width accuracy it is important that the

operator is aware that the sprayer is pushed in a manner that keeps

the nozzle constantly parallel with the ground.

To aid accuracy use a proprietary spray dye indicator which allows

the operator to see where they have sprayed. Contact your local

landscape supplier for a recommendation.

After use

1.

Empty any unused contents out of the spray tank. The S15 SPRAY-PRO tank has been designed to easily empty and clean.

Dispose of

the tank contents and all washings in accordance with the manufacturer’s disposal instructions on the product that has been used.

2.

Wash out the tank thoroughly using clean water and or a preparatory tank cleaner. Make sure that the nozzle and spray gun (if included)

are thoroughly washed as well. To wash through the pipework to the spray nozzle, add an additional 1/2 gallon/2 liters of clean water to

the tank and wash this through the nozzle by pushing the sprayer over a safe area for the purpose of disposal of washings.

3.

Empty all water out of the sprayer making sure no water is left in the pump over winter - do not allow to freeze, unless you have setup

the S15 to operate in freezing temperatures using an Ice Melt or snow pre-treatment materials.

LITER GALLON

22

20

18

16

14

12

10

8

6

4

5

4

3

2

1

GROUND

4.

10

/3.5

0 -

4

Spray width

can change

if you lift or lower

the handle.

Position handle

to keep the nozzle

parallel with the surface.

LITER GALLON

22

20

18

16

14

12

10

8

6

4

5

4

3

2

1

GROUND

ADJUSTS 2”

4.

10

/3.

50 - 4

PAGE 4

FEA

THERED-EDGE

1X RATE

PATH IS

ONE WAY

2X RATE

PATH IS

BOTH WAYS

FEATHERED-EDGE

SPRAY TRANSPORT

SPR

AY

T

R

A

NSPOR

T

Spray Pattern

Most applications will only require

1 pass. When higher application rates

are required a cross pattern as shown

above should be used.