8

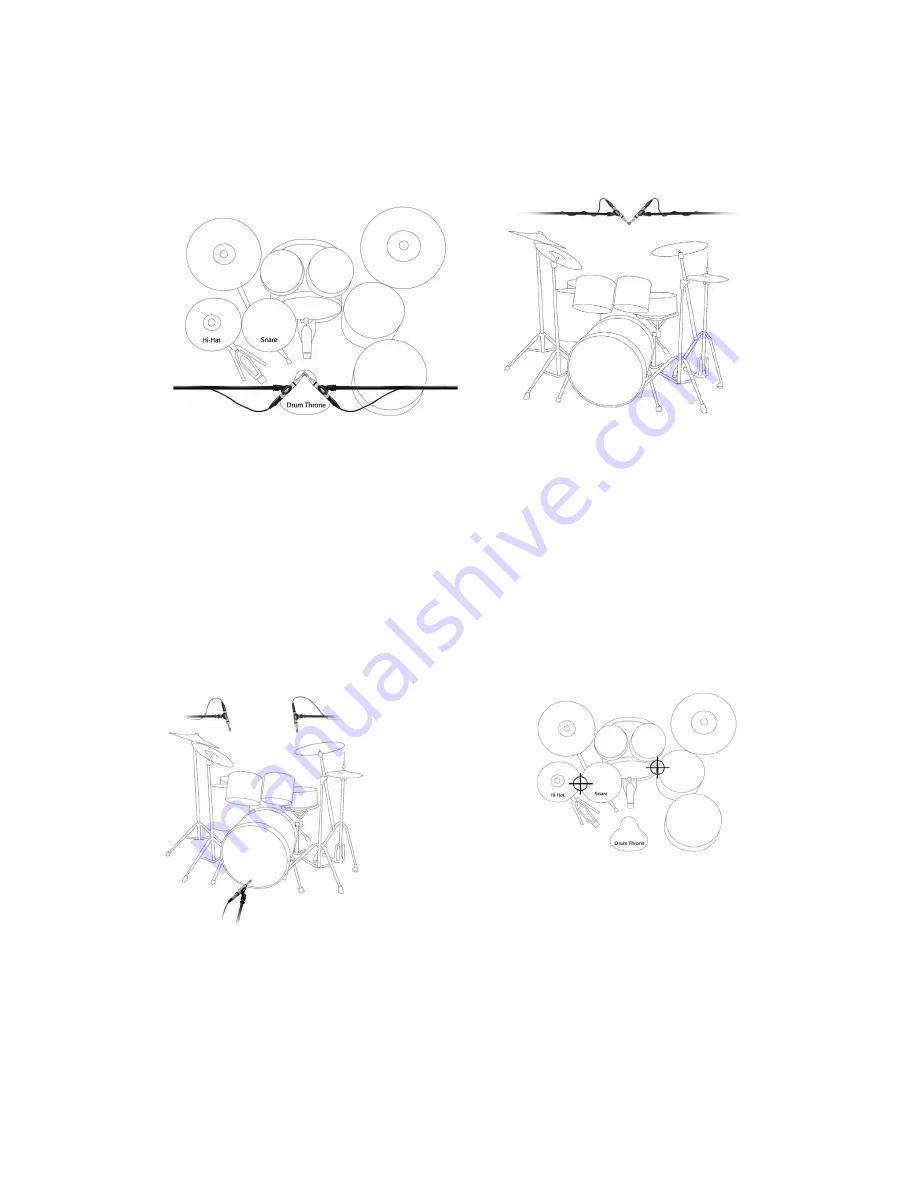

X/Y Stereo Overhead Miking

There are two basic ways to position overhead drum mics, either by placing the

mics in an X/Y position (Figures 12-A & 12-B) or by separating the microphones

by some predetermined distance (Figures 13-A and 13-B). The X/Y position will

provide less of a stereo image than the separated microphone method.

Figures 12-A and 12-B show two variations of X/Y microphone placement.

The suggested microphone “height” should be approximately 2 feet above the

drummer’s head. Moving the mics lower will provide more detail, while moving

them higher will capture a wider overall image of the drum set in addition to

more room sound. Both the horizontal and vertical X/Y positioning will provide

excellent results in a drum booth or an acoustically treated small room as well

as in a large room. If you are using a drum booth or a room with a low ceiling, the

horizontal X/Y version shown in Figure 12-A may be more ideal, as it typically

requires less height.

Figures 13-A and 13-B

A

Overhead miking

front view

B

Overhead miking

aiming positions

top view

A

B

Figure 12-A

Horizontal X/Y Positioning

Figure 12-B

Vertical X/Y Positioning

Separated Overhead Miking

Separated Overhead Miking (Figures 13-A & B) allows the microphones to

be placed further apart and they can also be positioned closer to the drum

than when using X/Y positioning. Placing the overhead mics closer to certain

elements of the drum set can reduce the ambient room sound while also

picking up more subtle details of the drums. When using Earthworks High

Definition Microphones as overheads, you can place the microphones closer to

the drums without fear of hearing cymbal splash or splatter.