10

A

B

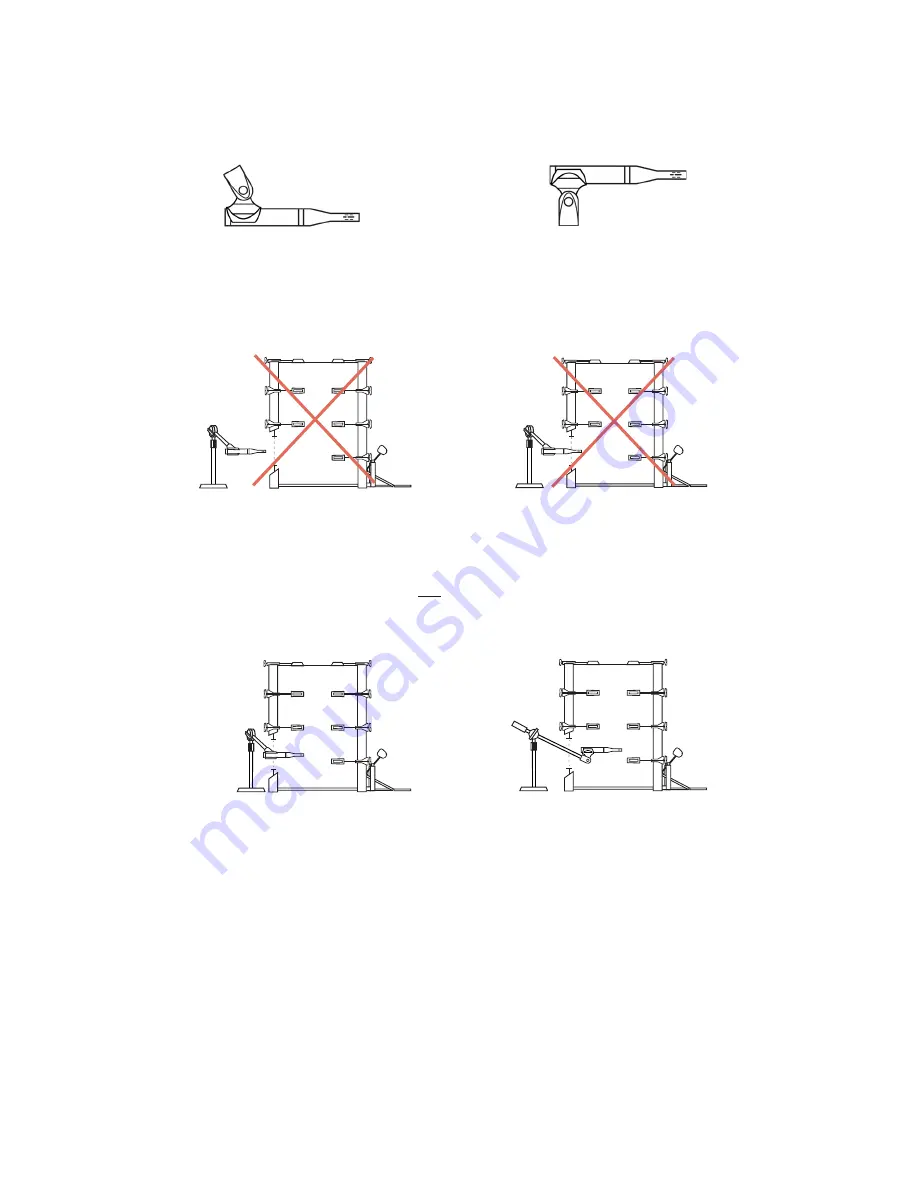

Figures 18-A & B High Air Velocity Close to Hole in Head

For optimum results place the microphone at least 6 inches inside the hole (Fig.

19-A) or closer to the beater head (Fig. 19-B). With the mic inside the kickdrum it

should be placed at an angle (mic tip not parallel to the head)

.

When using a taller mic

stand with the boom at an angle you cannot get the mic as far inside the kickdrum

as with a shorter mic stand and the boom parallel to the floor (Figures 19-A & 19-B).

B

A

Figures 19-A & B Suggested Miking inside Kickdrum

Miking a Kickdrum with a Hole in the Front Head

First, make sure the mic clip is attached all the way at the bottom (XLR end) of the

microphone allowing it to go deeper inside the kickdrum (Figures 17-A & 17-B).

When miking the kickdrum at the hole in the head keep in mind that the highest ve-

locity of air from the hole is closest to the outside or inside of the hole (Figures 18-A &

18-B) which could cause the microphone to pop.

A

For taller mic

stands with

angled boom

B

For short mic stands with

boom parallel to floor

Figures 17-A & B Attach Mic Clip at XLR End of the Microphone

EQ and Signal Processing

The SR20LS has a flat frequency response and in most cases you will need to EQ it

for kickdrum. Standard practice is to boost the low frequency range to make a kick-

drum sound fatter, and then boost the mid and/or high frequency range to hear more

snap from the beater. However, you may need to rethink this approach when using the

SR20LS with its extended low frequency and high frequency response compared to

most other popular kickdrum mics. This extended response may reduce the amount

of low and high frequency EQ that would typically be used when miking a kickdrum.

We suggest that you first listen with the EQ “flat” (Fig. 20), with all other signal process-

ing turned “off.” You may be surprised how good this mic sounds all by itself. First,

try moving the mic around, whether placed inside or outside of the kickdrum for the

desired balance of beater sound and fat low frequency kickdrum sound.