Refrigerant Piping Connection

Note on Pipe Length

When connecting refrigerant piping, do not let substances or gases

other than the specified refrigerant enter the unit. The presence of

other gases or substances will lower the unit’s capacity, and can

cause abnormally high pressure in the refrigeration cycle. This can

cause explosion and injury.

Ensure that the length of the refrigerant pipe, the number of bends, and the

drop height between the indoor and outdoor units meets the requirements

shown in the following table:

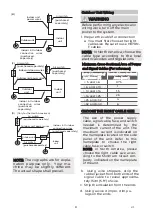

The Maximum Length And Drop Height Based on Models. (Unit: m/ft.)

Type of model

Capacity (Btu/h)

Length of piping

Maximum drop height

North America,

Australia and the

EU frequency

conversion Split

Type

<15K

25/82

10/32.8

≥15K - <24K

30/98.4

20/65.6

≥24K - <36K

50/164

25/82

≥36K - ≤60K

65/213

30/98.4

Other Split Type

12K

15/49

8/26

18K-24K

25/82

15/49

30K-36K

30/98.4

20/65.6

42K-60K

50/164

30/98.4

CAUTION

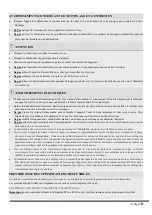

Oil traps

If oil flows back into the outdoor

unit’s compressor, this might cause

liquid compression or deterioration

of oil return. Oil traps in the rising

gas piping can prevent this. An oil

trap should be installed every 6m

(20ft) of vertical suction line riser (

<

36000 Btu/h unit).

An oil trap should be installed every

10m(32.8ft) of vertical suction line

riser (≥36000Btu/h unit).

6m/20ft

(

<

36000Btu/h unit)

10m/32.8ft

(≥36000Btu/h unit)

6m/20ft

(

<

36000Btu/h unit)

10m/32.8ft

(≥36000Btu/h unit)

Indoor unit/

Outdoor unit

Indoor unit/

Outdoor unit

Gas piping

Liquid

piping

Oil trap

27

V.1