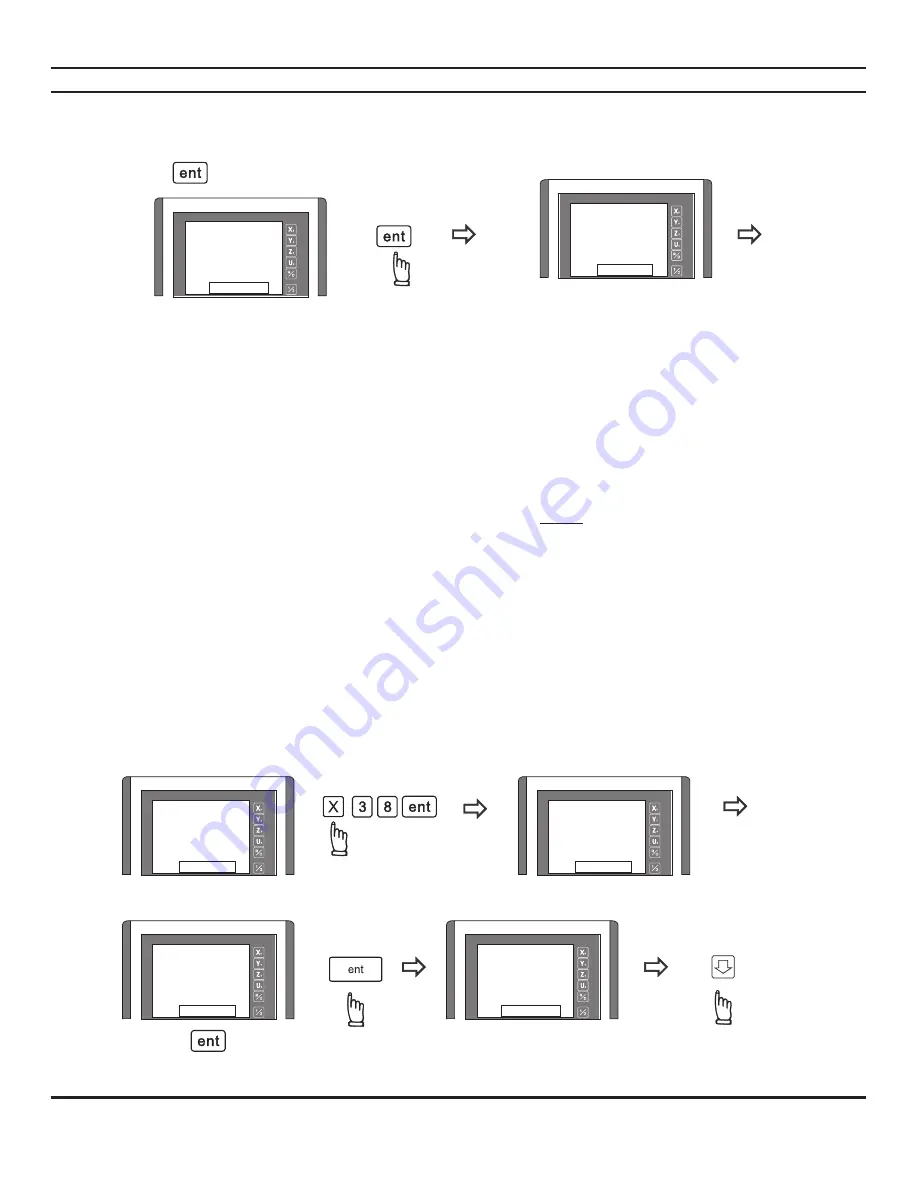

Parameters Setup Procedure - LIN COMP

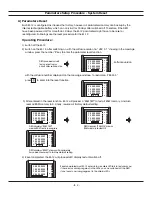

Press to select the "LIN COMP" selection menu

LIN COMP menu is designed to allow user to enter the Linear Compensation value of each axis. The entered

value must be in PPM ( Parts Per Million ). If the non-linear error compensation is in active, the Linear

Compensation will not be effective any more.

Linear Compensation value

of each axis is displayed on

the axis display respectively

The linear compensation value is specified in PPM [

P

(arts)

P

(er)

M

(illion) ], an example of calculating

the PPM value are as follows.

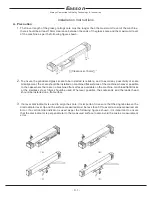

1. Measure the error using s step gauge or any other device ( e.g. guage block ) of an accuracy level

higher than the measuring resolution and the machine as a measuring standard. For example,

if you are using an 0.005mm resolution linear scale and the machine is expected to have an accuracy

of 0.02mm, the accuracy level of your measuring standard should be ideally at least one grade

higher, such as 0.001mm resolution and 0.01mm in accuracy.

2. The error must be recoded in metric unit ( um - micron - 0.001mm )

( e.g. we measure the X axis and record an display error of 19um shorter over a length of 500mm )

3. Project the error to over the 1 meter ( 1000mm ) in length

( e.g. in the above example, if measurement is 1000mm, the error will be

19um X (1000/500 ) = 38um )

4. Find the direction of error, if the DRO display longer than the measurement standard, then compensation

value should be NEGATIVE, and vice versa. In this example, we find the DRO display is shorter then the

standard, therefore compensation value should be an positive value, +38.

5. The PPM value is micron error extrapolated over a meter, the M(illion) referred to in calculation is

1 million microns to the meter.

( e.g. in the above example, the entry compensation value should be +38 )

Enter the X compensation value

then press to exist from

"LIN COMP" menu and return to

the top level menu

- B. 12 -

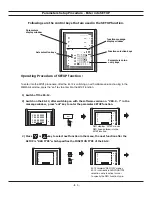

selection done

go to next menu

X

Y

Z

U

LIN. COMP

X

Y

Z

U

LIN. COMP

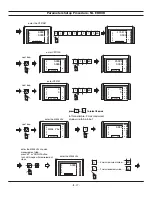

X

Y

Z

U

ENTR.PPM

0

0

0

0

X

Y

Z

U

ENTR.PPM

0

0

0

0

X

Y

Z

U

ENTR.PPM

38

0

0

0

X

Y

Z

U

ENTR.PPM

38

0

0

0

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...