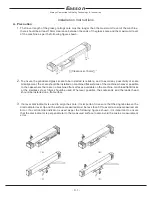

After the scale is aligned to the axis, then drill

and tap the scale to suit the bracket provided

and mount the bracket insuring that the reader

head is sitting correctly so that when the reader

head is attached it will be square and parallel to

the scale.

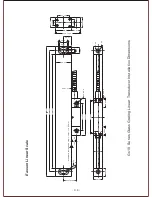

The"z" axis scale should be installed on the side of

the column insuring that the open side of the scale is

away from direct swarf and coolant and that the travel

is in the right direction "-" towards the spindle and "+"

away from the spindle. (Fig.1) The bracket is (Fig 2)

mounted of the knee, and around the scale to allow

f o r t h e c o v e r ( F i g . 3 ) t o p r o t e c t t h e s c a l e w h e r e

excessive coolant & swart are present.

Mount the bracket on the saddle to take

the reader head making sure that the

reader head is in line and parallel to the

scale. Secure the cable making sure to

leave enough free cable to allow for the

travel of the slide.

Fitting the "Z" Axis

Before mounting the scale insure that it will read"+"as you wind the table down, increasing the distance

from the table to the cutter

Fig.1

Fig.2

Fig.3

Always Committed to Quality Technology & Innovation

Easson

- C. 7 -

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...