- 21 -

REF datum memory function - working principal

Function :

In daily machining process, it is very common that the machining cannot be completed within

one work shift, the DRO have to be switched off after work hours, or power failure happen

during the machining process which inevitably lead to the lost of work piece datum ( work

piece's ABS zero position ), the re-establishment of work piece datum using edge finder or

other method is inevitably induce higher machining inaccuracy because it is not possible

to re-establish the work piece datum at the exact position as per the previous datum.

To allow the recovery of work piece datum very accurately, and no need to re-establish the

work piece datum using edge finder or the other methods, every glass grating transducer

have a

REF

mark which is a fixed position in the glass grating transducer. We can simply

store the relative distance between the work piece datum and this

REF

mark into the DRO's

memory, after recovered from a power failure, we can re-install the stored relative distance

from the

REF

mark to re-establish the work piece datum.

Followings are the detail work principal of the

REF

datum memory :

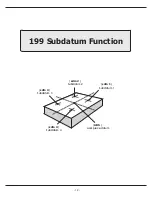

- there are a permanent and fixed mark ( position ) in the center of every glass grating scale,

normally it is called

REF

mark or

REF

point.

- since this

REF

point position is permanent and fixed, it will never change or disappear even

when the DRO is switched off. Therefore, we can simply store the relative distance between

this

REF

mark and the work piece datum ( ABS zero position ) in the DRO's memory. Then

in case of power failure happen, after recovery from the power failure, we can use the

REF

datum memory function to re-install the store relative distance from the

REF

mark to

re-establish the work piece datum ( ABS zero position ).

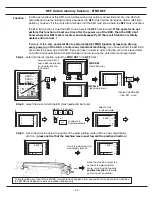

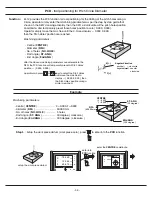

X axis

REF

mark position

( permanent and fixed )

glass grating scales

work piece datum

( ABS zero position )

relative distance between the

ref mark and work piece datum

after power failure, the work

piece datum ( ABS zero position )

to be recovered by preseting this

stored relative distance from the

ref mark position

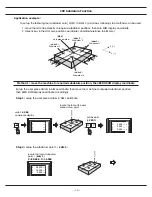

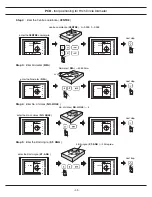

Example :

to store the X axis work datum

Operation :

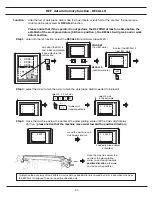

ES-12 provides one of the best and most easy to use

REF

datum memory function in this industry.

There is no need to store the relative distance between the

REF

mark and your work piece datum,

whenever you make any clear zsero, position preset or center find operating in ABS coordinate,

this relative distance is automatically stored into the battery backup or ferrite core permantent

memory, it will last so long as you don't change or update it, after you lost the work datum zero,

you simply use the

recall 0

function to restore your work piece datum.

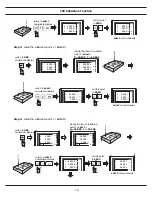

However,

you need to carry out the REF FIND function at least one time before you make

any important machining

. This is to let the DRO know where the ref mark is located.

It is a very

good practise to perform REF FIND function at least one time on every "power up" of the

DRO ( if possible ),

If you plan to machine an important or serious job,

please remember to

perform REF FIND at least one time before you start any important machining.

Only

perform REF FIND one time is enough for every switch on of the DRO.

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...