- 35 -

PCD

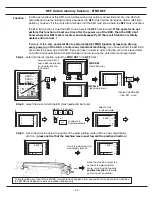

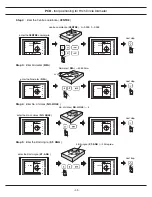

- tool positioning for Pitch Circle Diameter

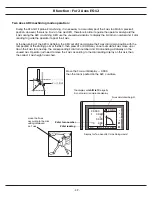

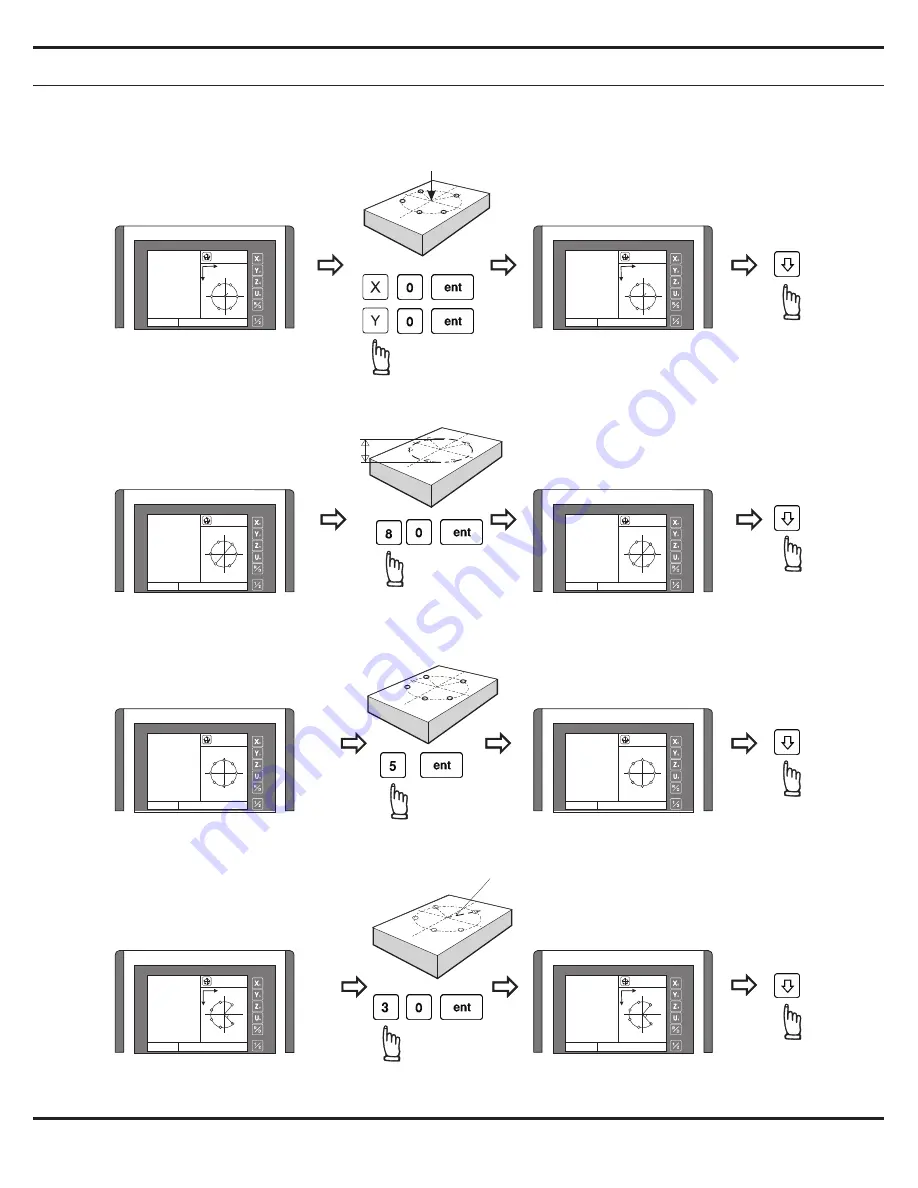

Step 3

: Enter Diameter (

DIA

)

Step 4

: Enter No. of Holes (

NO. HOLE

)

Step 5

: Enter the Start angle (

ST. ANG

)

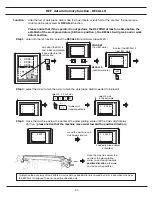

next step

next step

next step

enter the Diameter (

DIA

)

enter the No. of Holes (

NO. HOLE

)

enter the Start angle (

ST. ANG

)

Diameter (

DIA

) = 80.000mm

No. of Holes (

NO. HOLE

) = 5

Start angle (

ST. ANG

) = 30 degree

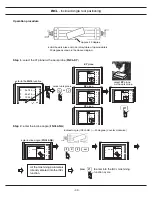

80.000

enter the

CENTRE

coordinate

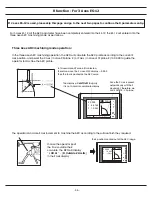

centre coordinate (

CENTRE

) : X=0.000, Y=0.000

Step 2

: Enter the Centre coordinate (

CENTRE

)

next step

1

2

3

4

5

X

Y

Z

ABS

CENTER

PCD

Y

X

0.000

0.000

CENTER

X

Y

Z

ABS

CENTER

PCD

Y

X

0.000

0.000

CENTER

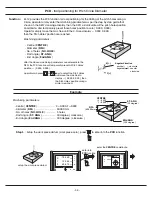

X

Y

Z

ABS

DIA. ?

PCD

0.000

DIA

X

Y

Z

ABS

DIA. ?

PCD

80.000

DIA

X

Y

Z

ABS

NO.OF HOLE ?

PCD

0

NO.HOLE?

1

2

3

X

Y

Z

ABS

NO.OF HOLE ?

PCD

5

NO.HOLE?

1

2

3

X

Y

Z

ABS

ST. ANG

PCD

0.000

Y

X

ST.ANG

X

Y

Z

ABS

ST. ANG

PCD

30.000

Y

X

ST.ANG

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

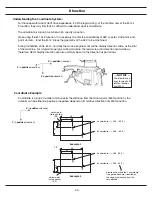

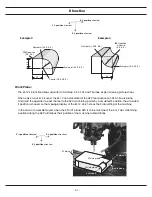

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

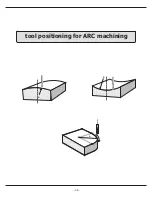

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...