- 37 -

PCD

- tool positioning for Pitch Circle Diameter

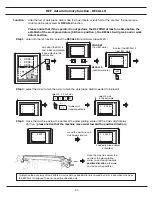

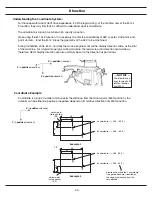

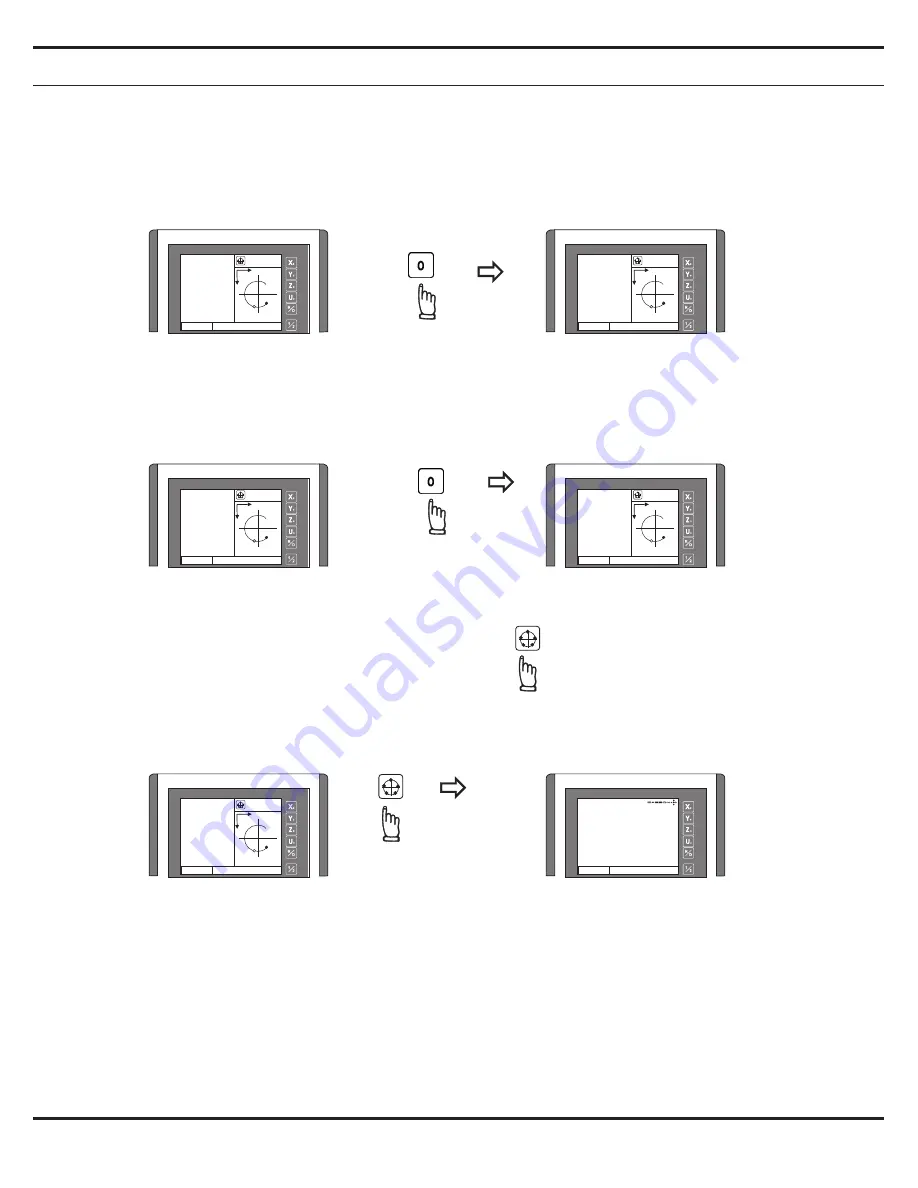

Anytime the operator want to check or verify if the DRO's PCD calculation correct or not, or want to

temporarily exit the PCD function cycle ( swap back to normal XYZ display ), procedure are as follows :

presently in

PCD

cycle

temporarily return to

XYZ coordinate display

presently in the temporarily

XYZ coordinate display

presently in

PCD

function cycle

temporarily swap to normal

XYZ coordinate display

swap back to

PCD

function cycle

swap back to

PCD

function cycle to continue the PCD machining operation

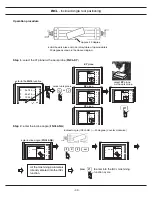

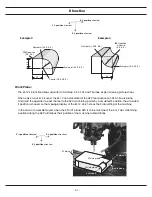

After all Pitch Holes machining operation completed, press to exit from the PCD function cycle.

exit PCD function, return to

normal display

X

Y

Z

ABS

XY=0: HOLE 1

PCD

0.000

0.000

0.000

Y

X

X

Y

Z

ABS

XY=0: HOLE 1

PCD

0.000

0.000

0.000

Y

X

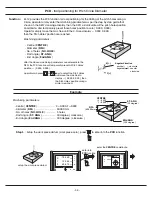

X

Y

Z

ABS

XY=0: HOLE 1

PCD

0.000

0.000

0.000

Y

X

X

Y

Z

ABS

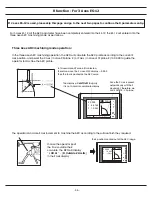

XYZ-ABS.

PCD

12.345

0.000

-78.560

Y

X

X

Y

Z

ABS

XYZ-ABS.

PCD

12.345

0.000

-78.560

Y

X

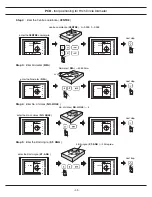

X

Y

Z

ABS

mm

mm

mm

-78.560

45.675

12.345

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...