- 48 -

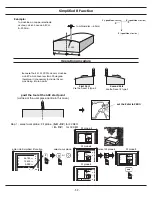

R function - For 2 Axes ES-12

The following procedure are for 2 axes ES-12, not valid for 3 axis ES-12.

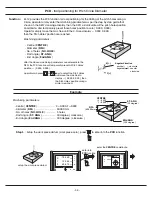

Step 8:

enter the Z increment per step machining

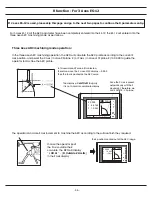

This DRO provides two options on the Z increment per UP or DOWN key press, Operator can enter their

selection in the R. MODE menu of the DRO's SETUP procedure.

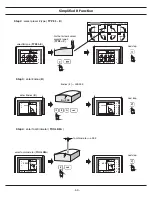

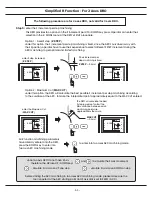

Option 1 : Fixed Z step (

Z STEP

)

under this option, the Z increment per step machining is fixed, since the ARC's curvature is vary with

their Z position, operator have to use their experience to select different Z STEP increment during the

ARC machining to get optimal and fastest machining.

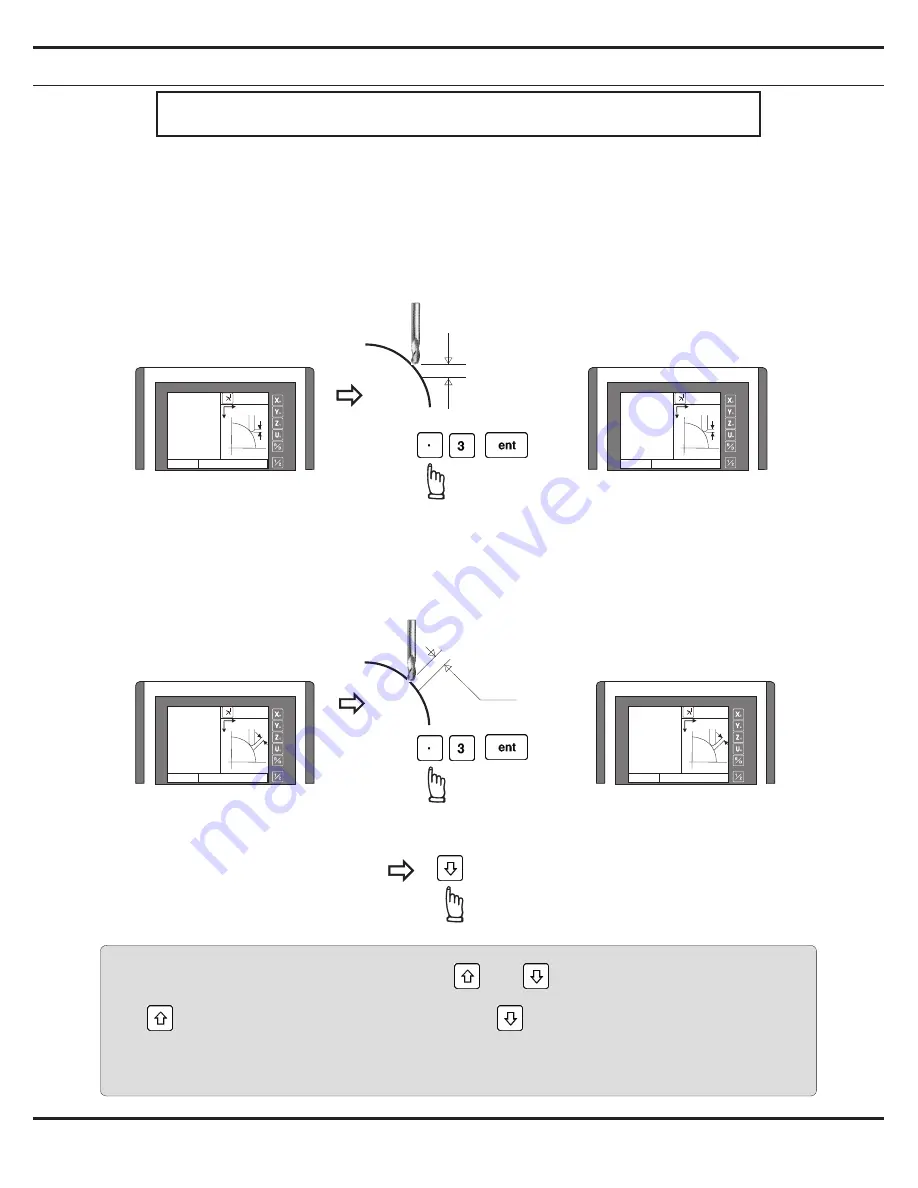

Option 2 : Maximum Cut (

MAX CUT

)

under this option, the DRO will calculate the best possible Z increment per step machining according

to the curvature of the ARC, to make the interpolated point approximately equal to the MAX CUT entered

enter Z step increment

(

Z STEP

)

Z Axis increment per

step machining is fixed

Z STEP

= 0.3mm

The DRO wil calculate the best

Z step increment so that the

Max. distance between each

machining points are

approximately the same

MAX CUT

= 0.3mm

enter the Maximum Cut

(

MAX CUT

)

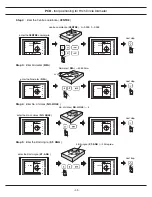

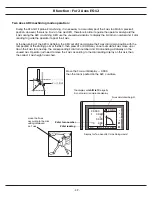

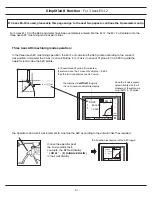

All R function machining parameters

have already entered into the DRO,

press the DOWN key to enter into

two axis ARC machining mode

to enter into two axes ARC machining mode

since two Axis ES-12 do not have Z Axis

therefore, the DRI use UP / DOWN keys

and

to simulate the Z axis movement

- simulate Z axis move UP one step

- simulate Z axis move DOWN on step

before starting the ARC machining in two axes ARC machining mode, please make sure the

tool is posited at the ARC starting point and Z axis dial is set to ZERO ( 0.00 )

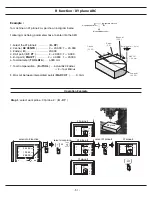

X

Y

Z

D

INC

R FUNC

Z Step increment ?

Z

X

R

0.000

Z STEP

X

Y

Z

D

INC

R FUNC

MAX CUT increment ?

Z

X

R

0.000

MAX CUT

X

Y

Z

D

INC

R FUNC

MAX CUT increment ?

Z

X

R

0.300

MAX CUT

X

Y

Z

D

INC

R FUNC

Z Step increment ?

Z

X

R

0.300

Z STEP

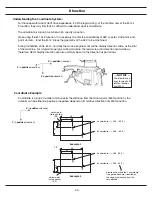

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

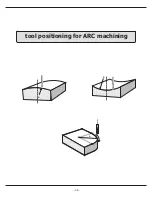

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...