- 50 -

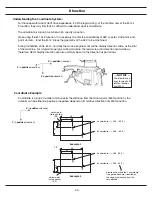

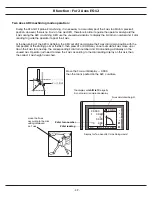

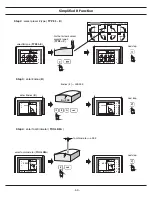

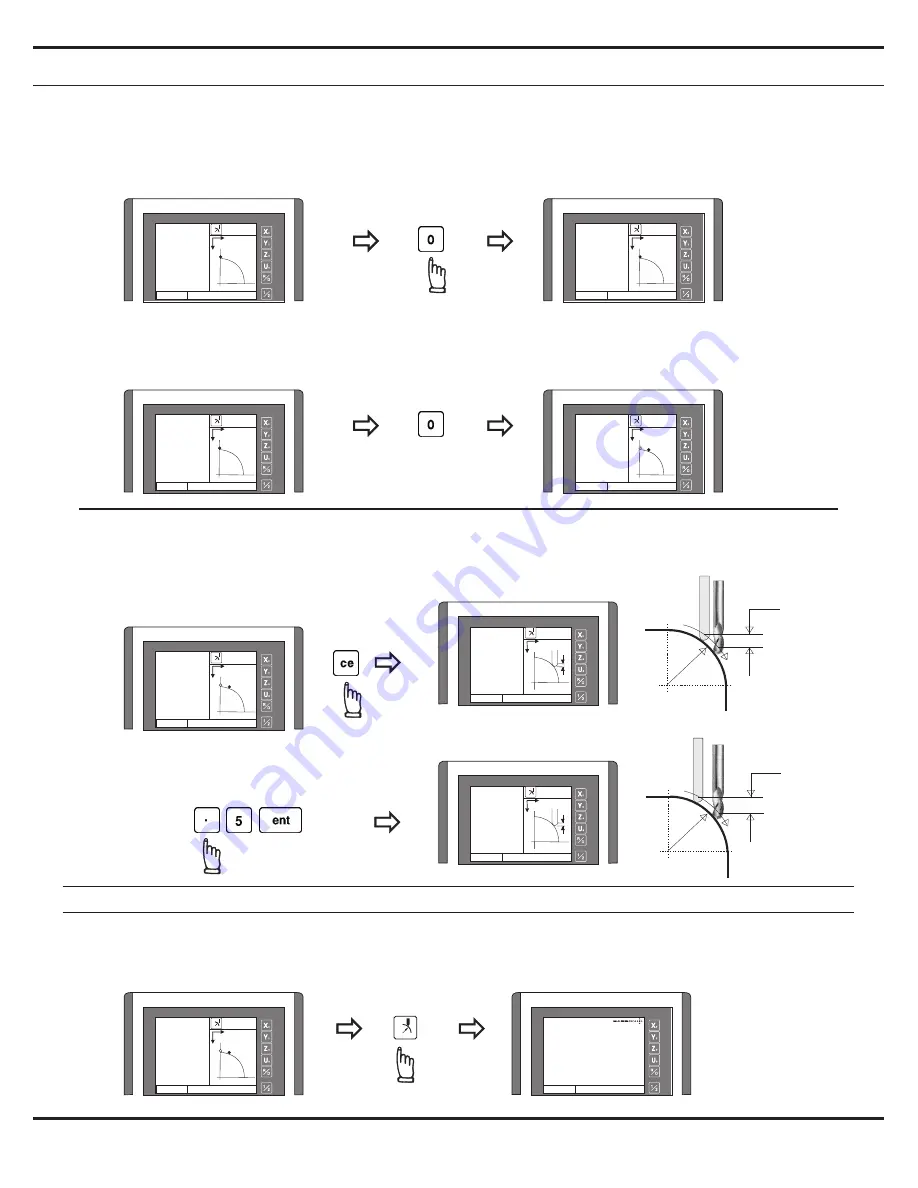

Anytime the operaor want to check or verify if the DRO's ARC calculation correct or not, or want to temporarily

exit the ARC function cycle ( swap to normal XYZ display ). Operation proceduer are as follows :

presently in ARC cycle

temporarily

swap

to normal

XYZ coordinate display

temporarily return to

XYZ coordinate display

swap back to ARC machining cycle to continue the R machining process

Presently in the temporarily

XYZ coordinate display

swap back to

ARC machining cycle

return to ARC function cycle

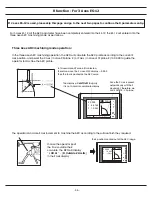

R function - For 2 Axes ES-12

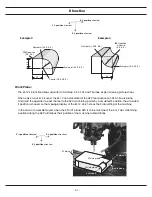

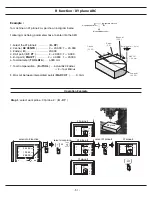

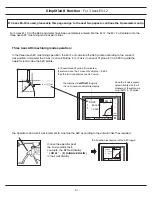

If fixed

Z STEP

option is choosed in the R MODE menu of SETUP , the

Z STEP

increment can be changed anytime

during the ARC machining

currently

Z STEP

increment =

0.3mm

change the

Z STEP

change

Z STEP

increment =

0.5mm

now the

Z STEP

increment = 0.5mm

R

0.3

R

0.5

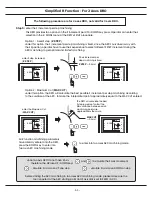

Afte the ARC machining operation is completed , to quit from the ARC function cycle, press the ARC buttion

key again.

presently in ARC function cycle

R

Quit from the ARC machining Cycle

X

Y

INC

R FUNC

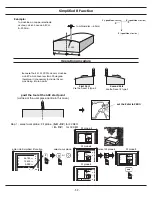

Auto R in XZ plane

Z

X

R

0.000

0.000

0.00

0

0.000

X

Y

INC

R FUNC

Simul R in XZ

Z

X

R

0.000

0.000

0.00

0

0.000

X

Y

INC

R FUNC

Simul R in XZ

Z

X

R

0.000

0.000

0.00

0

0.000

X

Y

INC

R FUNC

Simul R in XZ

Z

X

R

0.000

0.000

0.00

0

0.000

X

Y

INC

R FUNC

XYZ - INC

Z

X

R

-78.560

0.000

0.00

0

12.345

X

Y

INC

R FUNC

XYZ - INC

Z

X

R

-78.560

0.000

0.00

0

12.345

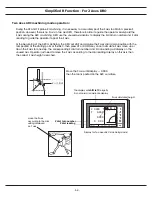

X

Y

Z

D

INC

R FUNC

Z Step increment ?

Z

X

R

0.300

Z STEP

X

Y

Z

D

INC

R FUNC

Z Step increment ?

Z

X

R

0.500

Z STEP

X

Y

INC

mm

mm

40.000

45.785

Summary of Contents for ES-12

Page 8: ...1 Basic Fucntions Basic Functions BASIC...

Page 15: ...8 Built in Calculator Calculator...

Page 27: ...20 REF datum memory...

Page 31: ...24 LHOLE tool positioning for the Line Holes...

Page 35: ...28 INCL Inclined angle tool positioning...

Page 40: ...33 PCD tool positioning for Pitch Circle Diameter...

Page 45: ...R R R 38 tool positioning for ARC machining...

Page 63: ...R R R 56 Simplified R function...

Page 73: ...66 Shrinkage Calculation L L X 1 005...

Page 91: ...Parameter Setup B 1 SET UP...