25

d

2

actual pitch diameter P

pitch

/2

tooth type angle

D

3-pin diameter M

distance between the two outer enveloping planes of

the 3-pin

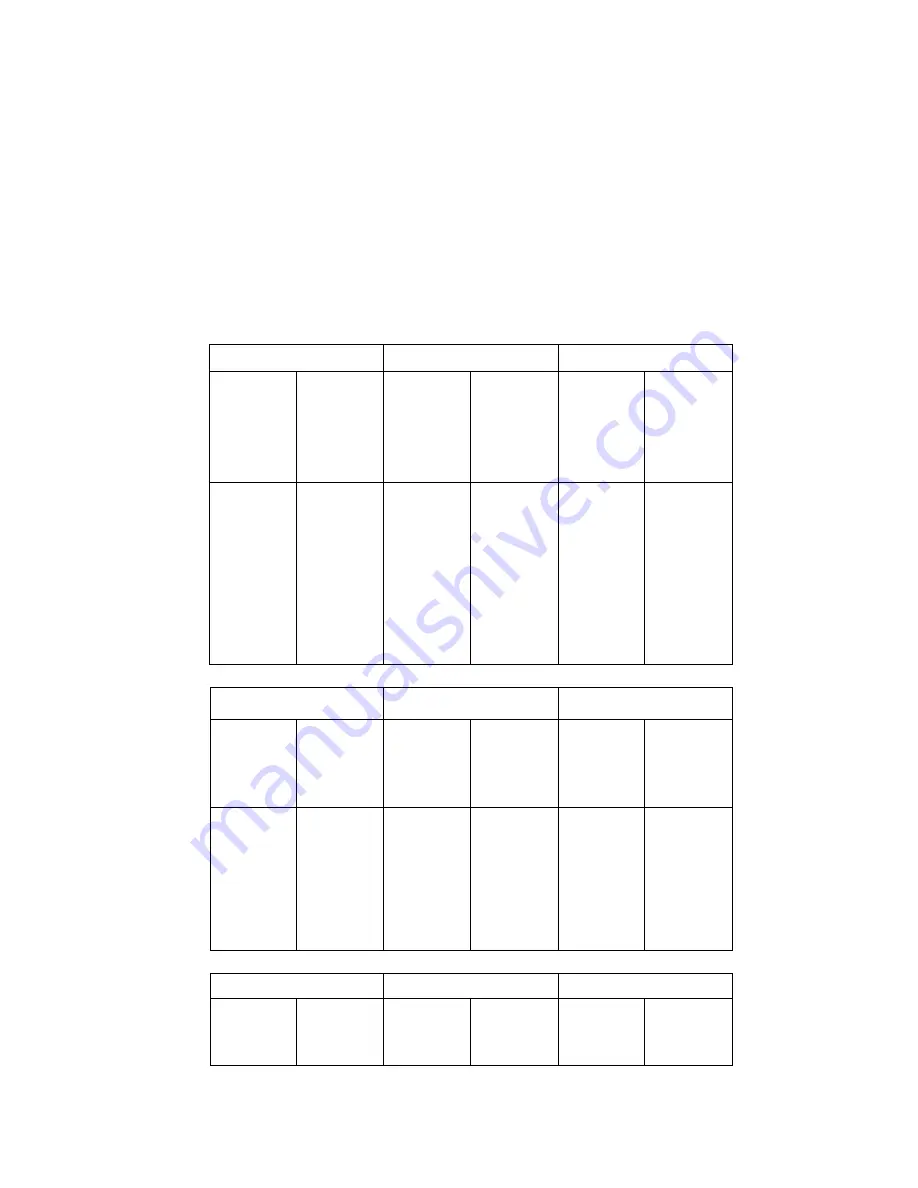

Selection of 3-pin diameter:

In order to minimize the error in measurement of the pitch diameter resulting in the

semi-angle error of tooth type, the selected 3-pin diameter shall make the contact point

between the 3-pin and the tooth approach the pitch diameter as possible. The optimum

3-pin diameter is selected according to the following table:

Metric thread

Metric thread

Metric thread

Pitch

P

mm

3-pin

diameter

d mm

P

mm

3-pin

diameter

d mm

Pitch

P

mm

3-pin

diameter

d mm

0.2

0.3

0.35

0.4

0.45

0.5

0.6

0.7

0.118

0.142

0.201

0.232

0.260

0.291

0.343

0.402

0.75

0.8

1.0

1.25

1.5

1.75

2.0

2.5

0.433

0.461

0.572

0.724

0.866

1.008

1.157

1.441

3.0

3.5

4.0

4.5

5.0

5.5

6.0

1.732

2.020

2.311

2.595

2.886

3.177

3.468

Imperial thread

Imperial thread

Imperial thread

Number

of

teeth

per inch

3-pin

diameter

d

mm

Number

of

teeth

per inch

3-pin

diameter

d

mm

Number

of

teeth

per inch

3-pin

diameter

D

mm

24

20

18

16

14

12

0.572

0.724

0.796

0.886

1.008

1.157

11

10

9

8

7

6

1.302

1.441

1.591

1.732

2.020

2.311

5

4.5

4

3.5

3.25

3

2.886

3.177

3.580

4.091

4.400

4.773

Step thread

Step thread

Step thread

Pitch

P

mm

3-pin

diameter

Pitch

P

mm

3-pin

diameter

Pitch

P

mm

3-pin

diameter

Summary of Contents for EX-100

Page 4: ...3 Fig 3...