User Manual 200 kVA-1200 kVA UPS

3 Installation

41

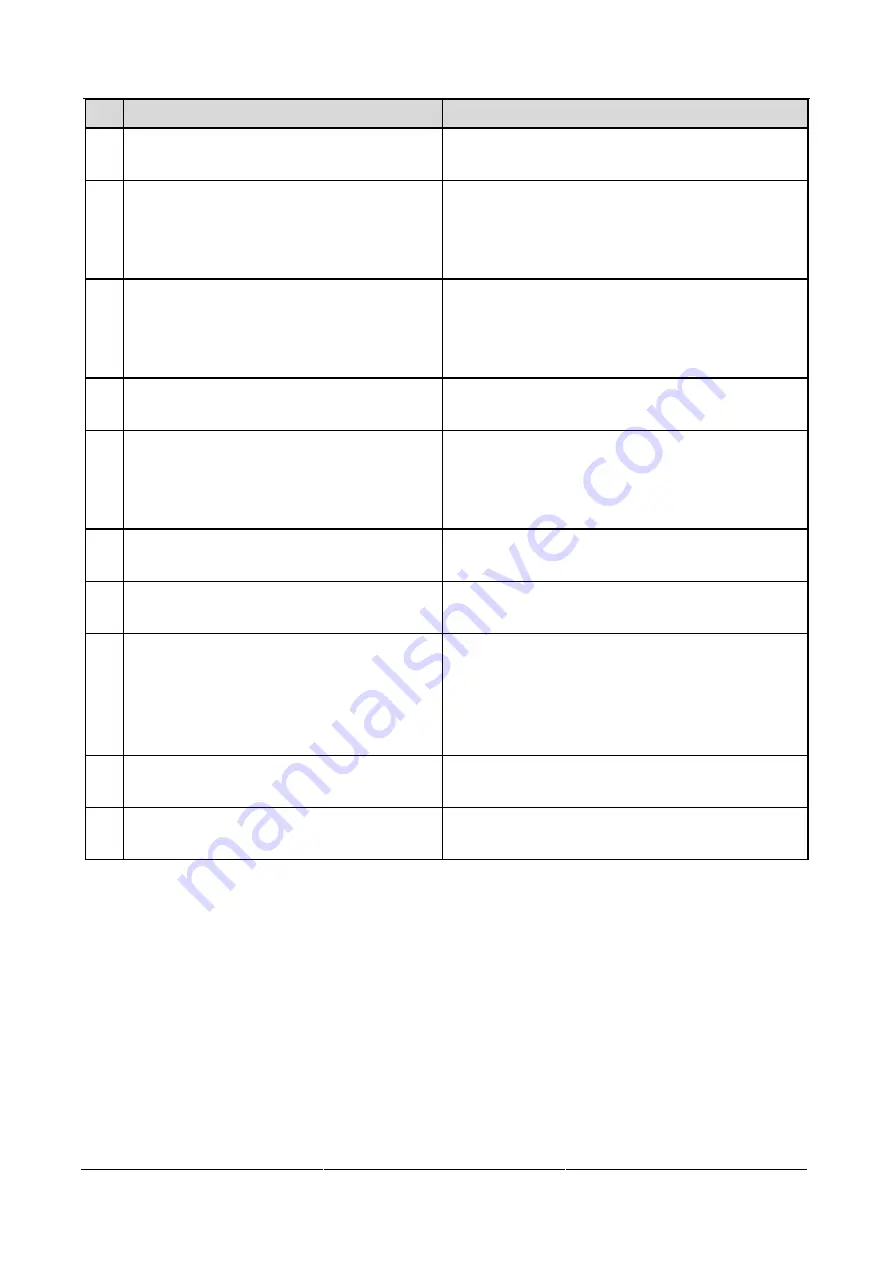

No. Inspection items

Acceptance criteria

2

Inspect whether during the cable layout, the

wiring of other systems is considered.

Reasonable layout of cables, and compliance with

construction requirements.

3

Check whether the input cable, the output cable

and the interbattery connection cable are tightly

connected.

All cable connections should not be loose. During

tightening the screws, make sure that the spring pad is

flattened to prevent falling off or safety accidents, and

ensure that there is no circuit breaking or hidden danger.

4

If a remote management device is used, inspect

whether the connection of the relevant serial port

(which supports security protection mechanism)

is correct.

The control cable must be properly connected and

tightened.

5

Check cable markings for clarity and accuracy.

Both ends of the cable should be labeled, and the label

should be concise and easy to understand.

6

Check whether the ground wire of UPS is

connected to the ground wire row of the machine

room, and whether the ground wire connection is

reliable.

Lead to the grounding bar in the machine room, and

connect firmly.

7

Check each cable connection.

Check for correct cable connection according to the

circuit diagram

8

Check whether the input wire and null wire are

inverted.

Live and null wires must be correctly connected.

9

For single UPS, check whether the phase

sequence of input line is correct; for parallel

UPS, check whether the main and bypass inputs

and outputs of each UPS are consistent with

phase sequence.

For single UPS, input phase sequence of UPS is correct;

for parallel UPS, the main and bypass inputs and

outputs of each UPS are consistent with phase sequence.

10

Check the running environment.

Remove electrical conductive dust and other sundries

inside and outside cabinet.

11

Check the short circuit between copper bars.

Use a multimeter to measure the short circuit between

copper bars.

Summary of Contents for EA990 Super

Page 1: ...200 kVA 1200 kVA ...