79

Phone:(910) 392

‐

2490

Fax: (910) 392

‐

2123

416 Landmark Drive

Wilmington, NC 28412

www.easterninstruments.com

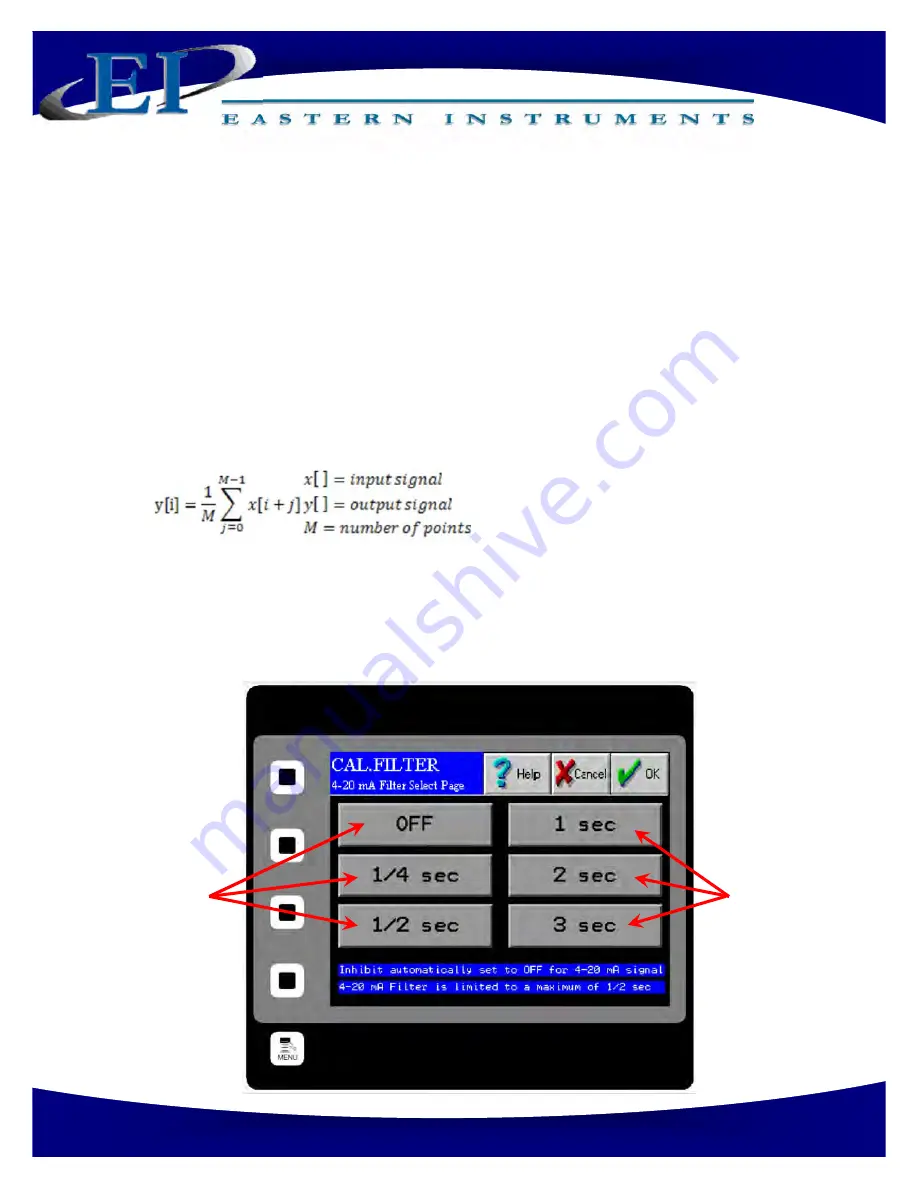

CAL.FILTER

CAL.FILTER is the Filter page. Access this screen by pressing the FILTER Bu on on the TOP.CAL

page a er pressing the CAL Bu on from the TOP page. This page is for selec ng the number of

points used in the 4

‐

20mA moving average

fi

lter. The formula for a moving average

fi

lter is

shown below. Press one of the Filter Bu ons to select the desired me increment for the

fi

lter.

For example, a me increment of 1 second will

fi

lter (or average) 200 samples of the input sig

‐

nal to create the 4

‐

20mA

fi

ltered output signal. This is because the transducer input sample

rate is 200 samples per second. The 4

‐

20mA output signal is updated at the same sample rate

as the input signal. However, the output signal will be delayed by the selected me. The mov

‐

ing average

fi

lter can also be turned o

ff

from this screen.

Moving Average Filter

The moving average is a very common

fi

lter in digital signal processing. Despite its simplicity,

the

fi

lter is op mum at performing the common task of reducing random noise while retaining

a sharp step response.

FILTER BUTTONS

FILTER BUTTONS