Maintenance 45

Caution!

Make sure the conveyor is stopped before putting your

fingers or anything else in the conveyor area.

3. Remove film residue. If necessary, use a dull blunt-edged tool. Do not use any

sharp instruments, as nicking silicone may result in damage that requires

replacing the roller covering.

To Clean Exit Rollers

Make sure rollers stay clean and grease free. If you should have to clean the rollers,

simply wipe them down with a clean lint free cloth. If a more thorough cleaning is

necessary wipe the rollers down with a mild detergent and water and let dry.

Never use

harsh or abrasive cleaners or chemical agents when cleaning the rollers.

Replacing Shrink Tunnel Conveyor Components

Caution!

Disconnect main power source before performing any

procedure to replace any conveyor component(s).

Roller Silicone Covering Replacement

1. Disconnect power to the machine.

2. Remove idler end caps, disconnect drive chain, loosen the four (4) bolts that hold

the drive motor and then, through the access hole, take the drive chain off the

drive motor sprocket.

NOTE:

You must take the chain off the drive motor sprocket or the

conveyor will not move freely. You must be able to move the

conveyor to replace silicone covering on the rollers.

3. Remove old covering by carefully slitting the covering and then pulling it off.

4. Clean all rollers using steel wool or a wire wheel. Make sure all rollers are

smooth and free of residue and burrs.

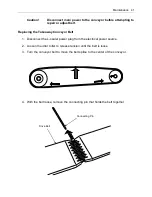

5. Fit the new silicone rubber tubing onto each roller and work on by hand at least

½ inch. At the opposite end of the tubing, fit on and secure an air supply hose of

low pressure, maximum pressure 5 lbs. While tubing is slightly expanded by air

pressure, push the tubing onto the roller and work it on to the roller. Be careful to

hold the roller at all times so it does not fly from the air pressure.

6. Replace rollers on conveyor by inserting roller end holes onto the extended pins

of the chain. Reconnect drive chain around drive motor sprocket. Adjust tension

on drive chain by tightening the four (4) bolts. Place access hole cover back on

and replace idler end caps.

Summary of Contents for Combination EC Series

Page 2: ......

Page 4: ......

Page 73: ...Appendix A Electrical Schematic 73 Electrical Schematic L Sealer ...

Page 81: ......