Operation 35

Setting Conveyor Belt Run and Stop Times

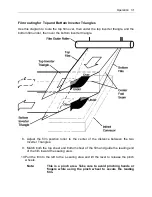

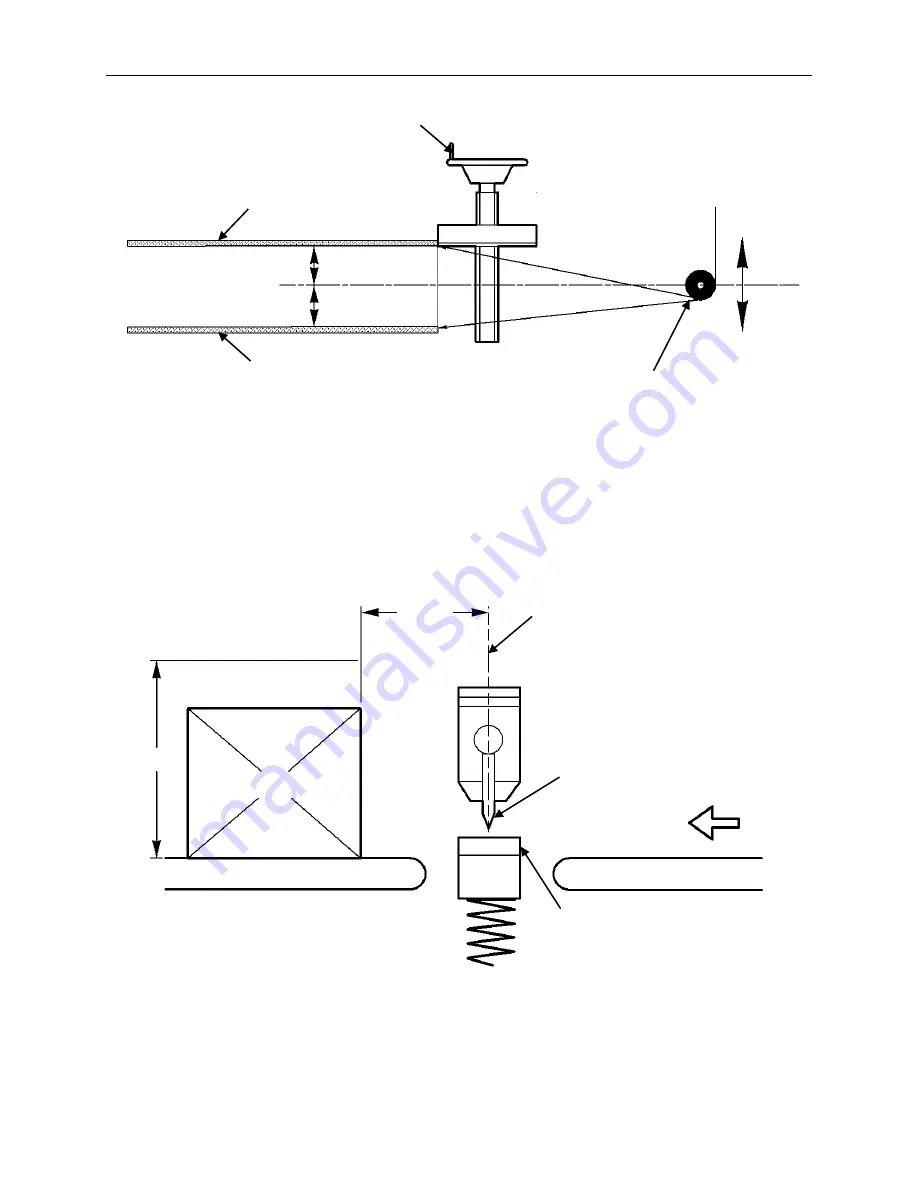

When the sealer is running and sealing product, the beginning transverse seal should

be made at a distance approximately ½ the product height ahead of the product

traveling on the Infeed Conveyor, then move to the Exit Conveyor and pause so that the

ending transverse seal is made ½ the product height behind the product, as shown in

the following illustration..

Seal Time, Advance, Stop, and Skip timers are set when creating a recipe for the

product and this information is provided in the Set Machine Timers section of the

instructions To Create, Name, and Save a Recipe section, earlier in this User Guide.

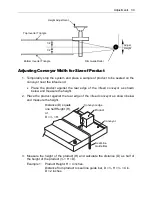

Top Inverter Triangle

Bottom Inverter Triangle

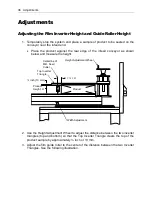

Height Adjustment

Film Guide Roller

1/2

1/2

Adjust

Height

Product

Infeed Conveyor

Exit Conveyor

Centerline of

T.D. Seal/Cutter Arm

½ × H =

D

T.D. Seal/Cutter Seat

T.D. Seal/Cutter Blade

Product

Height, H

Summary of Contents for Value VSA2530TK-V1

Page 1: ...VSA Value Series Auto L Sealers User Guide VSA2530TK V1 ...

Page 2: ......

Page 4: ......

Page 73: ...Appendix A Electrical Schematic 73 VSA2530 TKV1 Sheet 2 of 5 ...

Page 74: ...74 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 3 of 5 ...

Page 75: ...Appendix A Electrical Schematic 75 VSA2530 TKV1 Sheet 4 of 5 ...

Page 76: ...76 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 5 of 5 ...

Page 78: ...78 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 2 of 6 ...

Page 79: ...Appendix A Electrical Schematic 79 VSA2530 TKV2 Sheet 3 of 6 ...

Page 80: ...80 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 4 of 6 ...

Page 81: ...Appendix A Electrical Schematic 81 VSA2530 TKV2 Sheet 5 of 6 ...

Page 82: ...82 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 6 of 6 ...

Page 83: ...Appendix B Air Diagram Pneumatic Schematic 83 Appendix B Air Diagram Pneumatic Schematic ...

Page 88: ......