40 Adjustments

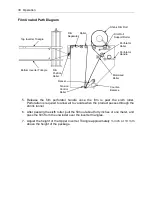

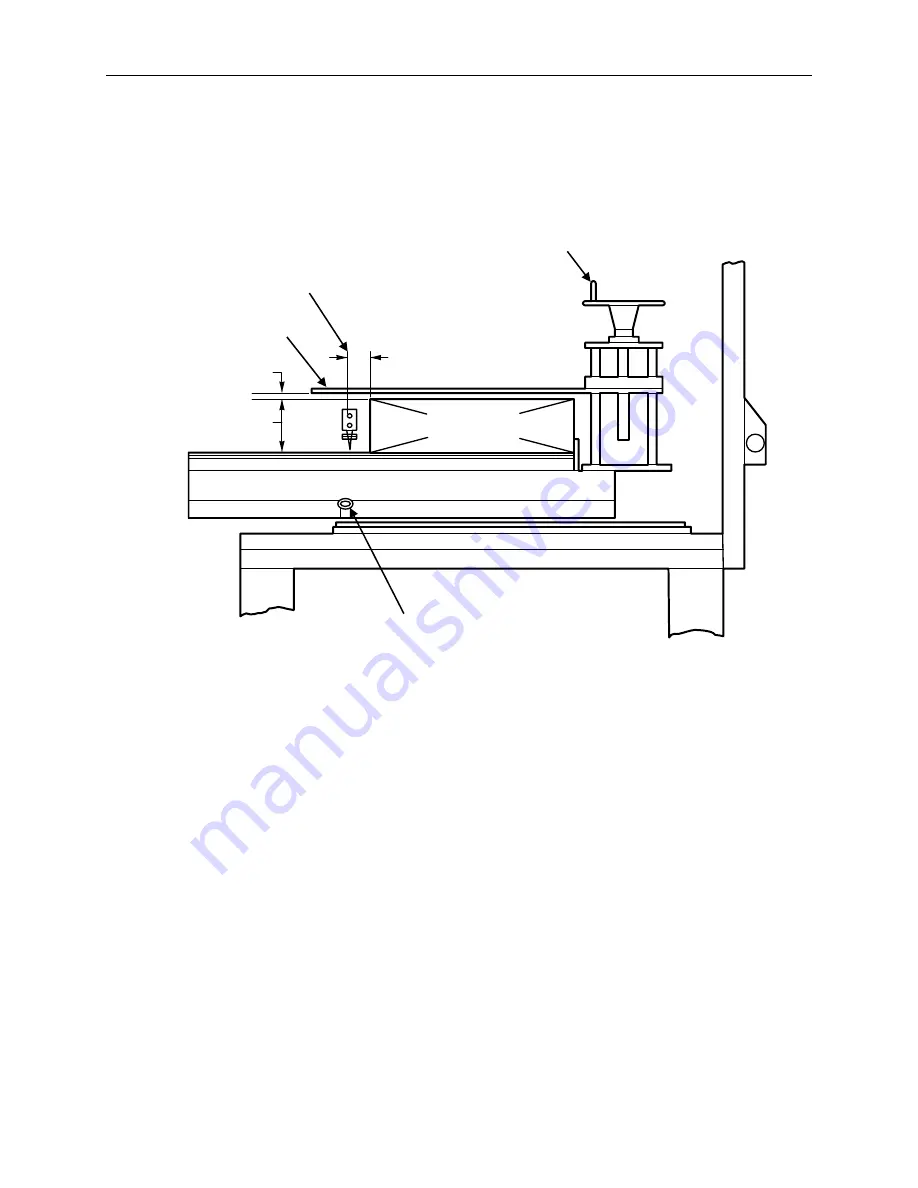

Example 2: Product Height, H = 7 inches.

Distance from product to seal line guide bar, D = ½ H = ½ × 7 in.

D = 3½ inches.

4. Use the Infeed Conveyor Width Adjustment to adjust the width of the infeed

conveyor to the calculated distance D.

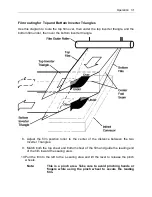

Setting Conveyor Belt Run and Stop Times

When the sealer is running and sealing product, the beginning transverse seal should

be made at a distance approximately ½ the product height ahead of the product

traveling on the Infeed Conveyor, then move to the Exit Conveyor and pause so that the

ending transverse seal is made ½ the product height behind the product, as shown in

the following illustration..

Height Adjustment Wheel

Product

D = ½ × H

½ inch (13 mm)

Product

Height, H

Width Adjustment

Top Inverter

Triangle

Centerline of

M.D. Seal/

Cutter

Summary of Contents for Value VSA2530TK-V1

Page 1: ...VSA Value Series Auto L Sealers User Guide VSA2530TK V1 ...

Page 2: ......

Page 4: ......

Page 73: ...Appendix A Electrical Schematic 73 VSA2530 TKV1 Sheet 2 of 5 ...

Page 74: ...74 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 3 of 5 ...

Page 75: ...Appendix A Electrical Schematic 75 VSA2530 TKV1 Sheet 4 of 5 ...

Page 76: ...76 Appendix A Electrical Schematic VSA2530 TKV1 Sheet 5 of 5 ...

Page 78: ...78 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 2 of 6 ...

Page 79: ...Appendix A Electrical Schematic 79 VSA2530 TKV2 Sheet 3 of 6 ...

Page 80: ...80 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 4 of 6 ...

Page 81: ...Appendix A Electrical Schematic 81 VSA2530 TKV2 Sheet 5 of 6 ...

Page 82: ...82 Appendix A Electrical Schematic VSA2530 TKV2 Sheet 6 of 6 ...

Page 83: ...Appendix B Air Diagram Pneumatic Schematic 83 Appendix B Air Diagram Pneumatic Schematic ...

Page 88: ......