9

Eastman

Over a Century of Cutting Expertise

®

Form E-564

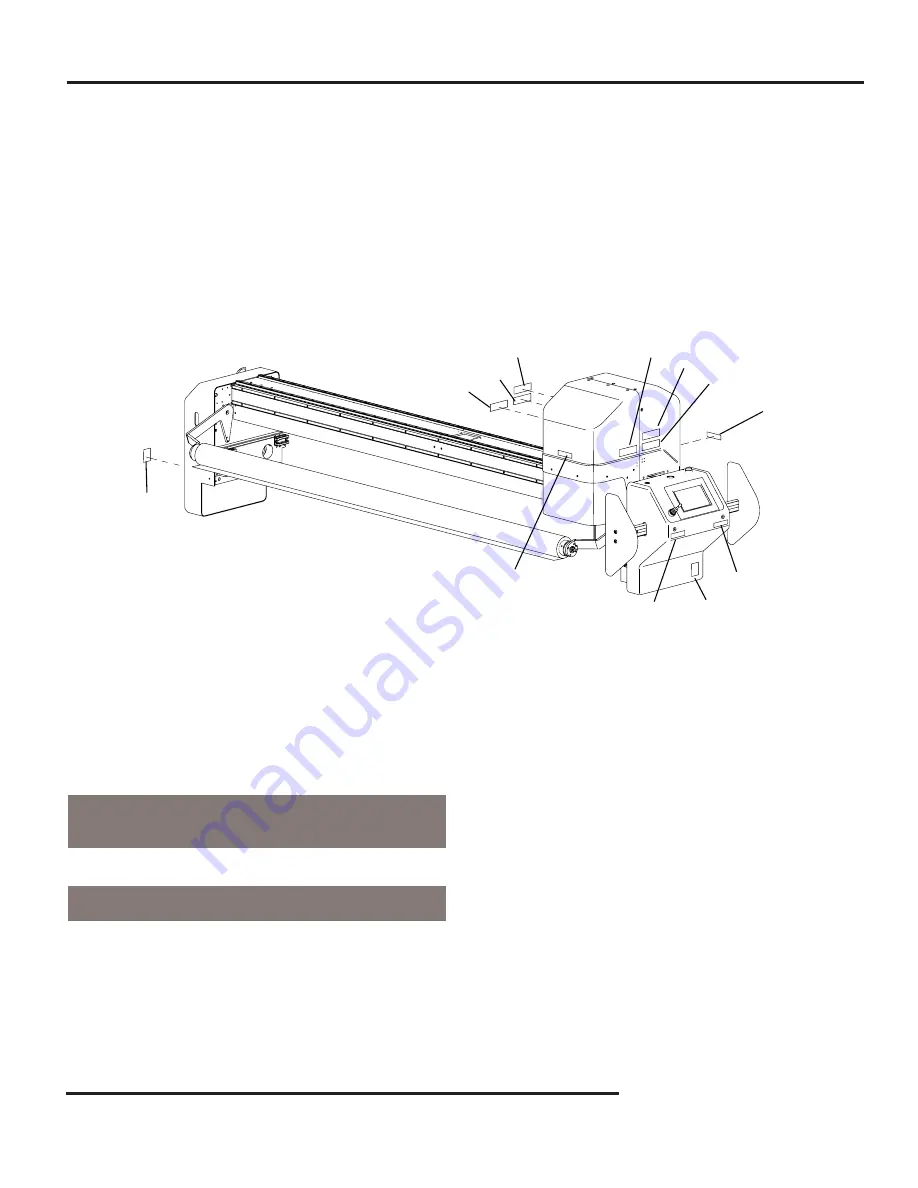

Raptor Gantry

Label Locations

ITEM PART NO.

DESCRIPTION

QTY.

1

91-26002

Decal, Small Eastman

1

2

91-26099

Decal, Raptor Logo (Blue)

2

3

91-26073-5

Decal, Guard Removal Med. 2

4

91-26073-2

Decal, Hazard Voltage

1

5

91-26073-10 Decal, Pinch Point

2

6

91-26073-3

Decal, Blade Hazard

2

7

91-26073-4

Decal, Guard Removal Sm. 2

3

3

4

2

5

6

7

5

7

6

2

1