To order parts and supplies: 800.343.9353 >> eastwood.com

9

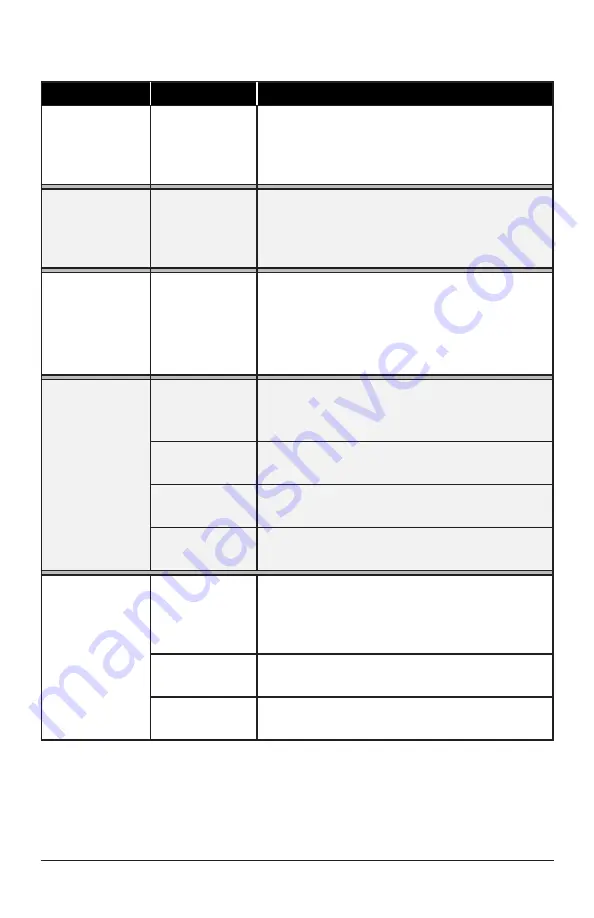

PROBLEM

CAUSE

CORRECTION

Gun Produces

an Uneven

Spray Pattern

or Fan

Paint or film

buildup on Air

Cap blocking

air holes

Disconnect air supply and clean buildup from

Air Cap.

Gun “Spits” or

Sputters; Dis-

charges Large

Droplets

Paint or film

buildup on

Needle &

Nozzle

Disconnect air supply and clean buildup from

Needle & Nozzle.

NOTE:

Use of solvent may be

helpful, removal of the Nozzle may be necessary.

Gun Dispenses

Only a Small

Amount of

Paint or None

at All

Clump or piece

of paint film

blocking paint

inlet port

Disconnect air supply; remove paint cup, remove

blockage from paint inlet area then strain paint

or coating to remove clumps or film.

Heavy

Textured or

“Orange Peel”

Paint Appear-

ance

Paint Gun is

too close to

surface

Keep within 8” to 12”.

Inlet air pres-

sure too low

Increase inlet air pressure and or decrease

fluid flow.

Incorrect thin-

ner/reducer

Check paint manufacturer’s reducing/thinning

instructions.

Incorrect mate-

rial mix ratios

Check paint manufacturer’s mix ratio instructions.

Excessive

Runs and Sags

Paint Gun

being moved

too slowly over

surface

Speed up gun motion over surface.

Excessive fluid

flow

Decrease fluid flow by adjusting “fluid” knob.

Paint mixed too

thin

Check paint manufacturer’s reducing/thinning

instructions.

TROUBLESHOOTING