6

Eastwood Technical Assistance: 800.544.5118 >> techelp@eastwood.com

To order parts and supplies: 800.345.1178 >> eastwood.com

3

6.

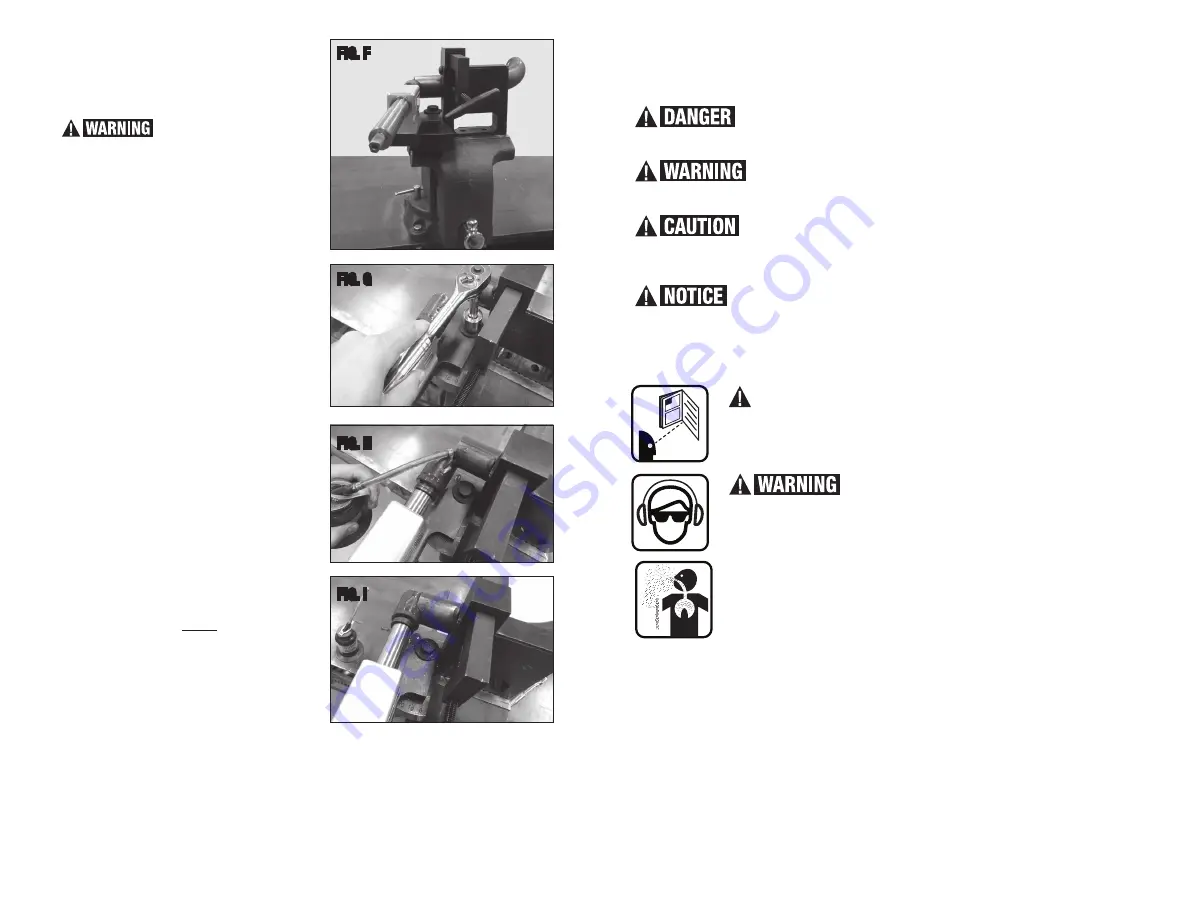

Be sure the base of the Eastwood Tubing

Notcher is securely mounted to a stable

work surface or clamped tightly in a solidly

mounted vice of substantial size.

(FIG. F)

Severe personally

injury can occur if the unit is not securely

mounted!

CUTTING/NOTCHING TUBING WITH

THE EASTWOOD TUBING NOTCHER:

1.

Determine the angle of the notch or

“fishmouth” to be cut in the tubing, loosen the

lock bolt slightly and adjust the Arbor

Carrier to the desired angle using the gauge

and tighten the lock bolt securely.

(FIG. G)

2. Place the tubing into the “V” notch and tighten

down the Tubing Clamp with the “T” handle.

Note:

Always make your “fishmouth” at the

end of a pre-cut section of tubing, never in the

middle of a longer piece. Keep the cut line from

going beyond the centerline of the hole saw.

(FIG. H)

3. For less heat buildup, longer saw life, and

minimal vibration, slower saw speed is better.

Some high strength steels, however, cut better

at slightly higher speeds. A variable speed drill

is useful for controlling the saw speed. Be sure

to use plenty of cutting oil on the metal saw

teeth and feed the saw slowly.

(FIG. I)

4. It is strongly recommended that several

practice cuts be made on scrap tubing to

increase familiarity with the tool and its set-up

before working on a valuable project.

FIG. F

FIG. G

FIG. H

FIG. I

• Read and understand all instructions before using this machine.

Save this instruction manual for future reference.

• Keep out of reach of untrained persons and children.

HEALTH HAZARDS

• Exposure to the loud noise of cutting can cause hearing loss. Wear hearing

protection when using this tool.

• Dust created by sawing can contain hazardous materials. Wear a NIOSH

approved respirator when sawing treated lumber, masonry products, or

items painted with lead-based paints.

SAFETY INFORMATION

In this manual, on the labeling, and all other information provided with this product:

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION used with the safety alert symbol, indicates a hazardous situation which,

if not avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.