To order parts and supplies: 800.345.1178 >> eastwood.com

9

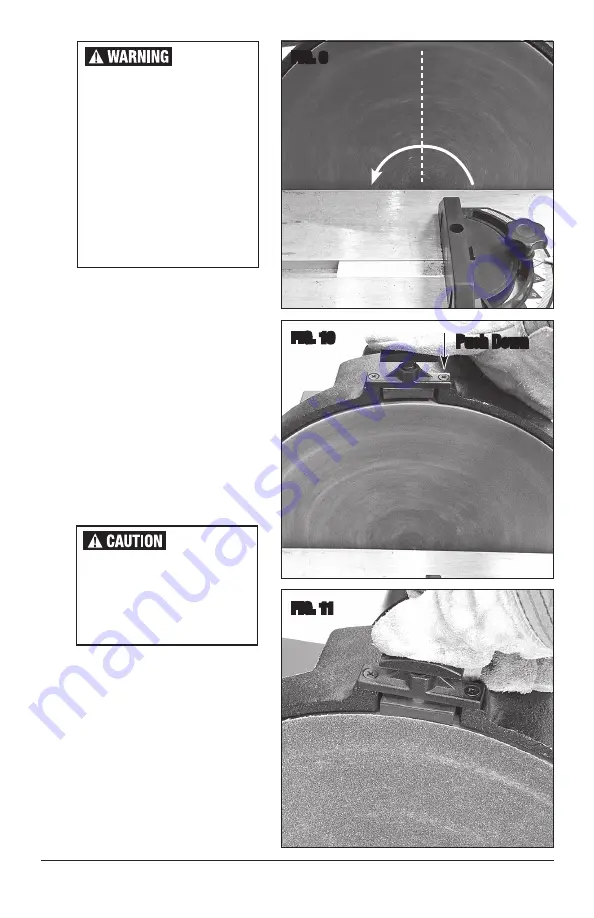

FIG. 9

FIG. 10

FIG. 11

Keep your body and any

objects out of the path of the

sparks which will be ejected

at high velocity form the face

of the Sander!

• The Plunger Brake is intended to

stop the rotating Disc immediately.

To do so, push down firmly on the

spring-loaded plunger to engage the

Brake

(FIGS 10 & 11)

.

• Be sure the Yellow Safety Key is

installed in the end of the Rocker

Switch and move the Switch to the

up “ON” position to run the Sander

motor. Allow the Blade to reach full

operating speed.

• Slowly feed the material into the

LEFT SIDE

of the Disk letting the

Sanding Disk do the sanding or

grinding. DO NOT apply excessive

force or serious personal injury,

death and or serious damage to the

Sander can occur.

WARNING!

Only Work

From Left Side!

Push Down

✓

The Disk rotates in a Counter-

Clockwise direction when

viewed from the front.

Always sand or grind using

only the LEFT SIDE of the Disk

(FIG 9). Working from the

right side can cause objects

to be suddenly and violently

ejected outward causing

severe personal injury and or

property damage.

Rotation