6

Eastwood Technical Assistance: 800.343.9353 >> techelp@eastwood.com

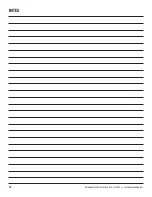

FIG. 11

FIG. 12

FIG. 13

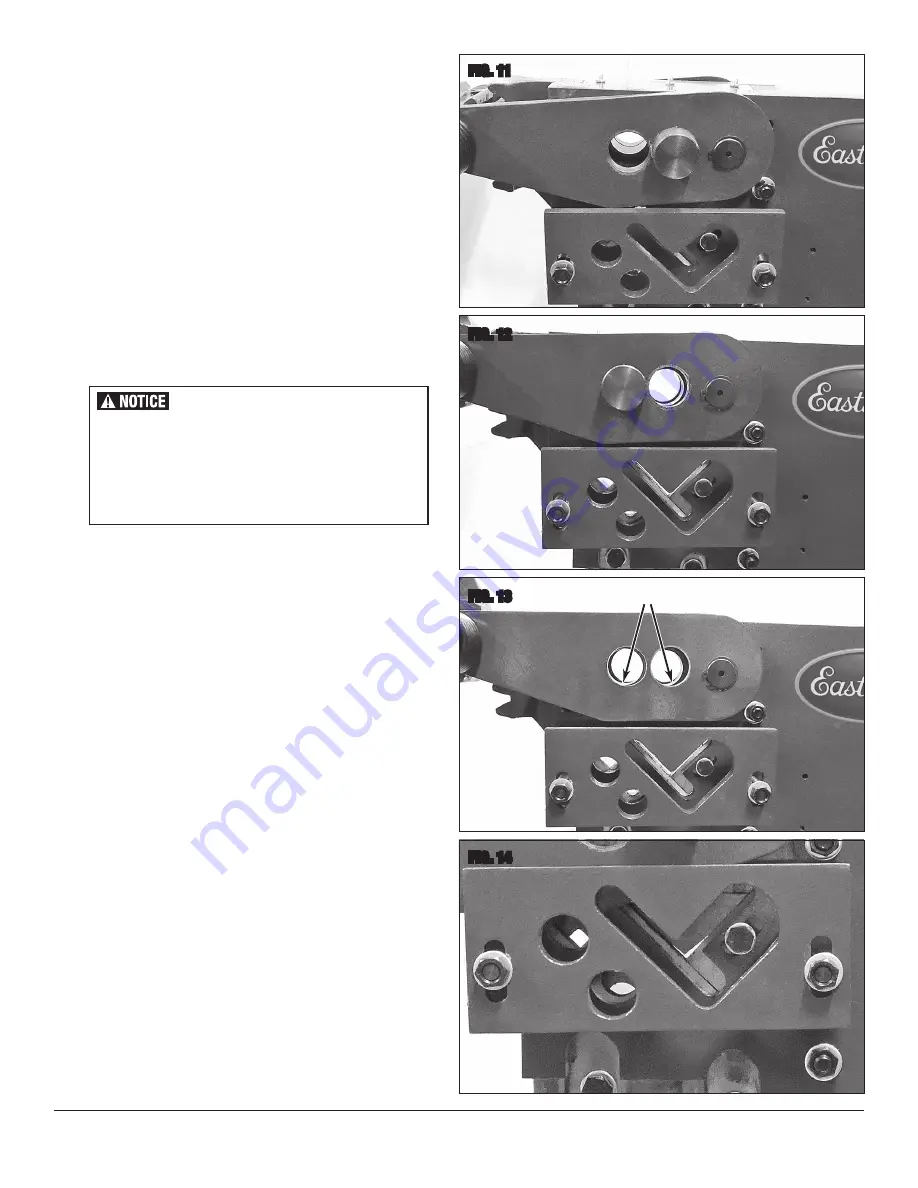

FIG. 14

ADJUSTMENTS

• Pivot Pin

The Eastwood Manual Ironworker design incorporates a moveable Pivot

Pin which modifies the cutting pivot point.

The factory installed position (rearward hole location) offers the greatest

leverage with the lowest Handle force required while causing greater lever

travel

(FIG 11)

. This is best when shearing thicker materials.

The alternate position (forward hole location) provides shorter lever travel

however it requires significantly greater lever force

(FIG 12)

. This may be

used on shearing lighter, thinner materials.

TO SWITCH PIVOT PIN POSITION:

- Remove Pivot Pin by griping the head firmly and rotating side to side

while pulling firmly. Carefully withdraw Pivot Pin and immediately

place it through the alternate pivot position

(FIG 12)

. Rotate Pivot

Pin side to side while pushing in.

• Right-Side, Round, Square and Angle Support Plate

The Right-Side Support Plate may be adjusted up or down to accommo-

date various sizes of material. To Do So:

- Loosen the 18mm Nuts

(FIG 14)

.

- Insert material to be sheared into the appropriate left side opening.

- Slide the Support Plate up or down as required to provide support

for the protruding material.

- Tighten the 18mm Nuts.

Do Not allow any components to move when

withdrawing Pivot Pin or Blade Drive Plate

misalignment can occur (Fig 13). Should this

occur, use of a screwdriver or magnet is advisable

to move the Blade Drive Plate back into alignment.

DO NOT use fingers!

Drive Plate

✓

✓