8

Eastwood Technical Assistance: 800.343.9353 >> tech@eastwood.com

GENERAL USE OF

BUFFER/POLISHER

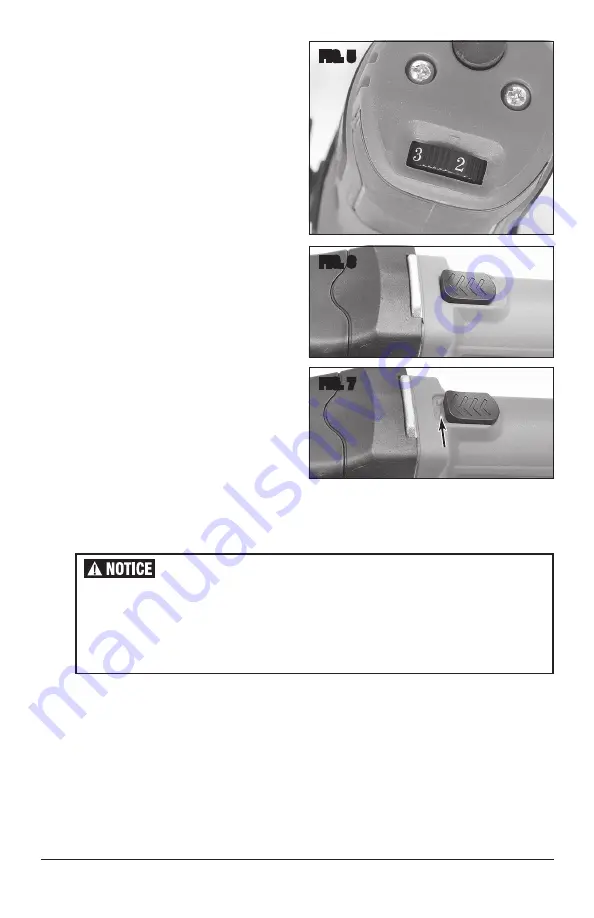

• Set the Speed Control on the desired

speed

(FIG 5)

. (See charts in appropriate

sections).

• While holding the Buffer/Polisher securely

in two hands, move the ON-OFF switch

to the forward, “ON” position.

NOTE:

The

built-in Soft-Start feature will cause a

slight delay in motor starting and gradually

increase in speed. This feature is designed

to minimize splattering and flinging of

polishing compound.

• To stop, release the Switch and it will

spring back to the “OFF” Position.

• The Switch has a “Lock ON” feature. To

engage, move the Switch forward past

the detent into the “Locked ON” position

(FIG 6)

.

• To release the “Lock ON”, move the Switch

back past the detent to the “OFF” position

(FIG 7)

.

FIG. 5

FIG. 6

THUMBWHEEL SPEED NUMBER / RPM EQUIVALENCY

1

= 2000 RPM

2

= 2700 RPM

3

= 3500 RPM

4

= 4800 RPM

5

= 5900 RPM

6

= 6400RPM

The Thumbwheel Speed Control is infinitely variable and actual RPM will vary widely

based on the actual position of the Thumbwheel and numerous factors such as

actual current input to tool, rotating mass weight of pad and disk, ambient operat-

ing temperature and degree of tool wear. As a result, the following figures are only

approximate:

FIG. 7

Detent

✓