To order parts and supplies: 800.343.9353 >> eastwood.com

15

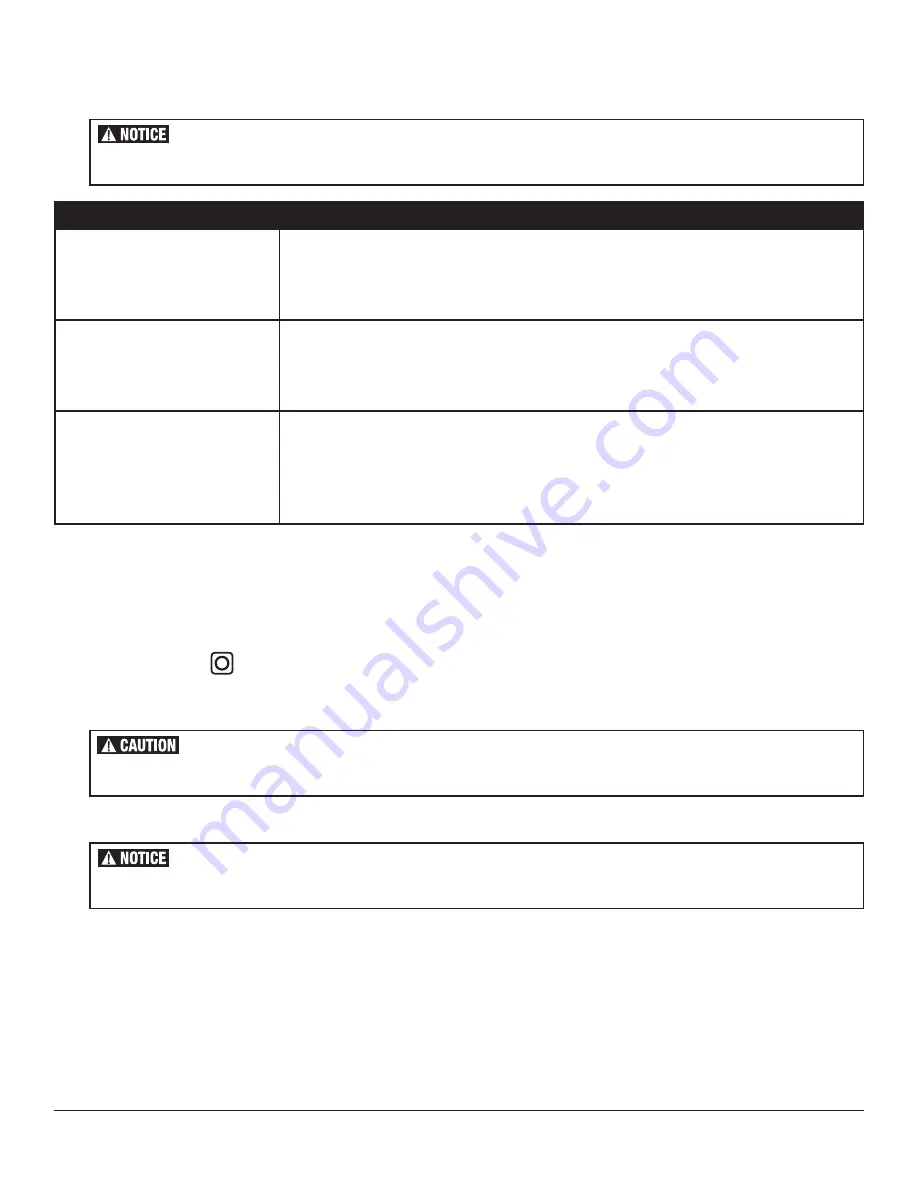

The following schedule should be adhered to for normal operating conditions. For operation in a harsh or dirty environment,

all maintenance intervals should be decreased by 20%.

Maintenance Interval

Maintenance Item

Daily

• Inspect Tank, Fittings and Lines for Damage or Leaks

• Drain Condensation Moisture from Tank

• Clear Dirt or Debris from Cooling Air Vents

• Check Oil Level

After First 500 Hours

• Replace Air Filter

• Change Oil

• Replace Oil Filter

• Check Electrical Connections

Every 6 Months or 1000 Hours

• Replace Air Filter

• Change Oil

• Replace Oil Filter

• Replace Oil/Air Moisture Separator Filter

• Clean Cooling Fins of Heat Exchanger

MAINTENANCE

MAINTENANCE SCHEDULE

DRAIN CONDENSATION

In normal compressor use particularly in humid environments, moisture will condense and collect in the tank.

All tanks must be drained of moisture daily. Failure to do causes internal tank corrosion, perforation and ultimate failure.

The following is the moisture draining procedure for the optionally available Eastwood #32501, 80 Gallon Vertical Tank: (other tanks supplied by customer may

vary in detail)

1.

Press the “OFF” Button and shut off main power.

2.

Release all pressure from the Tank until the Tank Pressure Gauge reads less than 20 PSI.

3. Slowly

open the Drain Valve of the tank (will vary with tank design).

4.

Drain moisture from tank into a suitable container.

• Clean dirt and debris from cooling air vents. Use a semi-firm brush or compressed air to keep cooling air passages free from dirt or debris accumulation.

Only SLIGHTLY open the water Drain Valve to blow air and moisture out of the Tank.

Opening it all the way or too quickly will cause contaminated water to be blown out at high velocity. Wear appropriate eye protection.

Condensate is a polluting material and should be disposed of in compliance with local regulations. If drain valve becomes clogged,

release all air pressure, remove and clean valve, then reinstall.