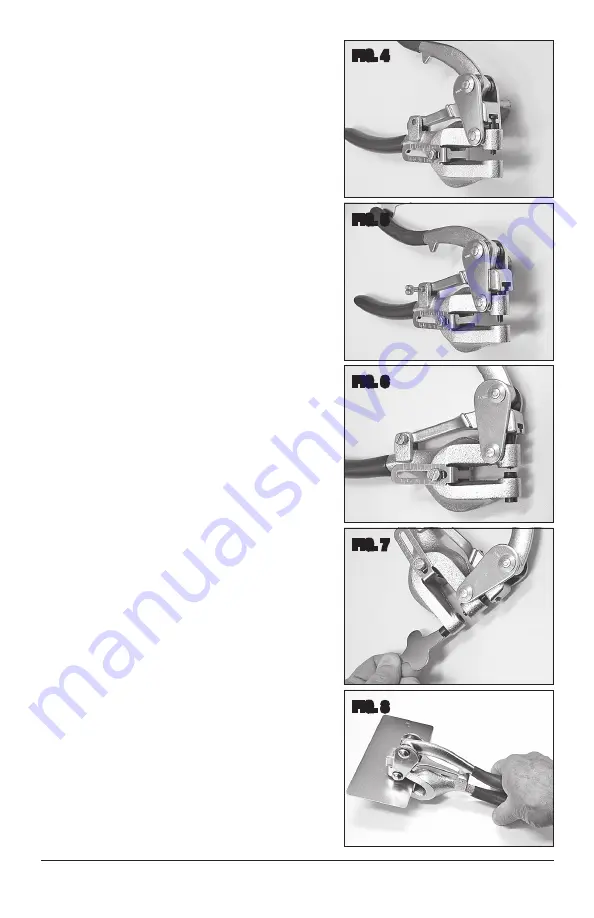

• Move the Upper Handle and Anchor Arm forward

capturing the “T” Head of the Male Die in the

“T” Slot of the Anchor Arm

(FIG 4)

.

• Re-install the Anchor Pin by aligning the pivot

bore of the Anchor Arm and the Main Body and

threading the Anchor Pin back into place

(FIG 5)

.

• Thread the corresponding sized Female Die into

the Lower Jaw with the Slot downward

(FIG 6)

and thread into place. If required, use the blade

end of the Die Installation Key to tighten the Die

in place

(FIG 7)

.

• Adjust the Lower, Female Die to allow the Upper

Male Die to fully engage the bore of the Female

Die when the tool Jaws are closed.

• The Metal Hand Punch is now ready for use.

OPERATION

• Before each use, inspect Punching Dies

for cracks and damage.

• Mark desired hole location and place the

workpiece under the center point of the

Upper Male Die.

• If desired, set Work Stop to the required depth.

• Raise Punch Upper Handle to open Punch.

• Insert material and lower Upper Lever to

close Punch.

• Slowly apply increasing pressure to the Punch

by squeezing the Upper Handle and Punch Body

Handles together

(FIG 8)

.

• Once the Die has punched through the metal,

open the Jaws to release the slug.

To order parts and supplies: 800.343.9353 >> eastwood.com

5

FIG. 4

FIG. 5

FIG. 6

FIG. 7

FIG. 8