To order parts and supplies: 800.343.9353 >> eastwood.com

7

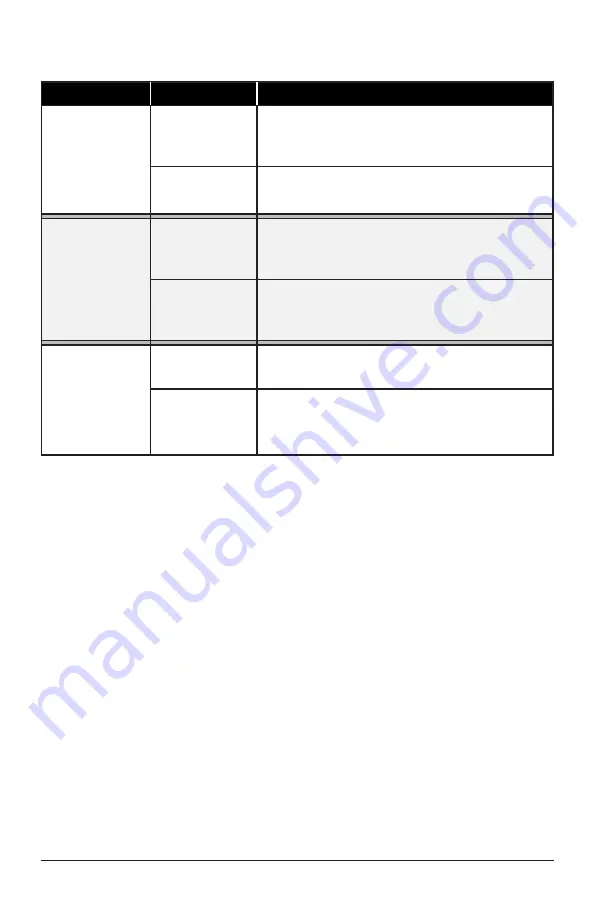

PROBLEM

CAUSE

CORRECTION

Upper Die

Stops At

Lower Die

Metal work-

piece too thick

or too hard

Stop all action to avoid serious damage.

Do not exceed material limitations described

in the “SPECIFICATIONS” section.

Metal slug

particles in Die

Stop all action to avoid serious damage.

Remove slug from Dies.

Upper Die

Binding at

Release With

Lower Die

Metal work-

piece too thick

or too hard

Stop all action to avoid serious damage.

Do not exceed material limitations described

in the “SPECIFICATIONS” section.

Metal chips

or particles

in Dies

Stop all action to avoid serious damage.

Remove chips or particles from Dies.

Dies Will Not

Shear Metal

Dies worn

or damaged

Follow Die Replacement instructions.

Metal work-

piece too thick

or too hard

Stop all action to avoid serious damage.

Do not exceed material limitations described

in the “SPECIFICATIONS” section.

TROUBLESHOOTING