10

Eastwood Technical Assistance: 800.544.5118 >> techelp@eastwood.com

To order parts and supplies: 800.345.1178 >> eastwood.com

7

TO BEGIN ABRASIVE BLASTING

IMPORTANT NOTES:

Start with all valves in the closed position.

Following the instructions below will help prevent the

formation of clogs in the Outlet Manifold, Abrasive Hose

the Safety Trigger and Nozzle.

Please note that as a result of many influencing variables

such as the available compressed air supply CFM and

pressure as well as the weight, density and grit size of the

selected media combined with atmospheric pressure and

humidity will all greatly affect the Blaster valve settings.

The set-up process requires some repeated “trial and

error” while following step 8 to achieve the best blaster

performance.

1.

Connect air compressor to the Inlet Connector.

2.

Open Air Supply Valve fully.

3.

Open Throttling Valve to approx. 1/2 way.

4.

Check for leaks at the Filler Cap and along all hoses

and fittings as the system pressurizes. If leaks are

observed, release the pressure from the tank and

repair immediately.

5.

Point Safety Trigger Nozzle in a safe direction away

from people, pets or anything around you that may

be harmed by direct or indirect high-pressure

abrasive stream.

6.

Press and hold Safety Trigger until air is flowing

through the Nozzle.

7.

While holding the Safety Trigger open, slowly open the Abrasive Control Valve until abrasive material begins to flow out of the

Safety Trigger Nozzle. Do not open Abrasive Control Valve any further at this point but follow procedure below.

8.

Abrasive Flow Adjustment as follows:

IMPORTANT NOTE:

The Abrasive Flow is a finely tuned combination of two adjustments (Throttling Valve and Abrasive

Control Valve) which will vary widely with different media, air supply and atmospheric conditions.

It is necessary to follow this “tuning” procedure at the beginning of every blasting job.

NOTE:

Operating the blaster with all valves wide open will result in decreased performance and effectiveness.

Too much air flow/not enough media will result in a high velocity but ineffective stream.

Too much media/not enough air flow will result in a soft, weak blast stream.

a.

Adjust air pressure with the Throttling Valve. The Throttling Valve controls the velocity of material flow.

b.

Adjust abrasive flow with Abrasive Control Valve. The Abrasive Control Valve controls the amount of abrasive introduced

into the stream.

c.

Increase Throttling Valve first in small increments followed by the Abrasive Control Valve second until an ideal smooth,

forceful flow is achieved.

d.

The above steps may need to be repeated in sequence until an ideal balance can be reached.

9.

Begin blasting.

10.

Drain moisture trap frequently during use. Do not allow moisture to fill more than 1/2 the water trap bowl. Do not leave water

standing in moisture trap when done blasting.

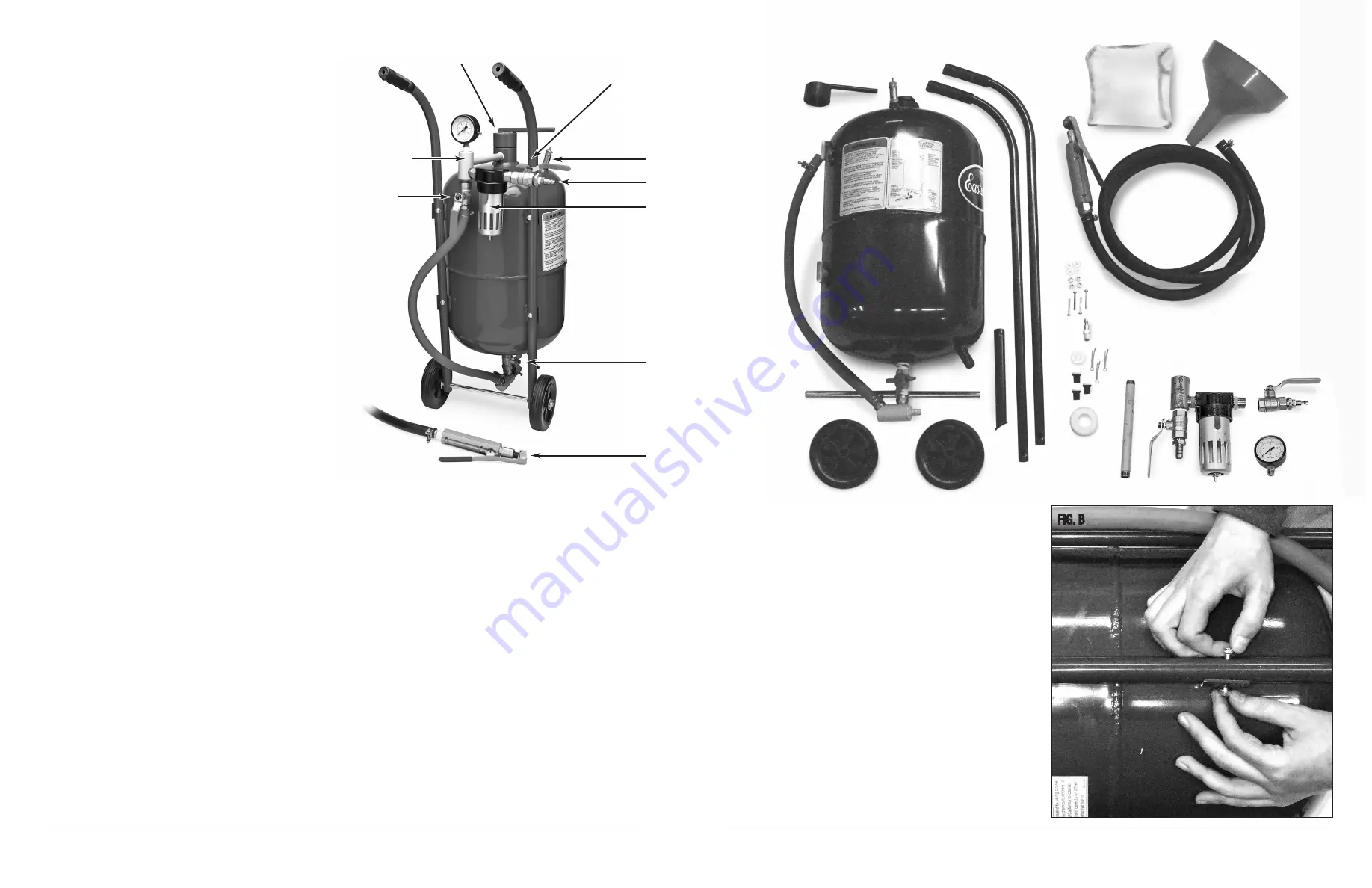

ASSEMBLY

1.

Remove parts from container and verify that all components

are present

(Fig A)

.

2.

Place Tank Assembly on a soft work surface for assembly with

the welded-on Handle Bar mounting tabs facing upward

(Fig B)

.

3.

Place left and right tubular Handle Bars (

NOTE:

2 pieces on

Item #’s 51117 & 51118. One piece Handle on #51119) over

the welded-on Handle Bar mounting tabs. The curved ends with

rubber hand grips should point upward and be oriented toward

the top of the Tank Assembly

(Fig B)

.

4.

Attach the left and right tubular Handle Bars to the 4 outward

curved mounting tank mounting tabs with 4 supplied 1-3/8” long

Phillips head screws and nuts. Note: Place screws through holes

with nuts and washers facing forward to avoid possible future

injury

(Fig B)

.

5.

Slide Axle through 2 holes in lower ends of tubular Handle Bars.

FIG. A

FIG. B

Filler Cap

✓

Inlet Manifold Assembly

Throttling Valve

Air Supply Valve

Pressure Relief Valve

Air Inlet

Moisture Trap

Abrasive Control Valve

Blast Hose and

Safety Valve Assembly

✓

✓

✓

✓

✓

✓

✓

✓