To order parts and supplies: 800.343.9353 >> eastwood.com

13

BUFFING OBJECTS

As with many skills, Buffing requires a learning curve to become proficient; however once learned,

will prove to be highly satisfying.

To get started, learn how to Buff as well as what not to do; a great source of guidance is item #13304,

Eastwood Art of Buffing

Instructional DVD.

It is highly recommended to practice buffing on some old objects of low value and experiment with

different metals Compounds and Buff Wheels. Generally, expect to spend some time and waste some

product before taking on something of value.

• Before turning on the Motor, take a few moments and plan the work to be done. Take notice of

all sharp edges, corners or protruding features that could snag the wheel. Be sure to plan on

buffing those areas with the wheel rotating away.

• Begin in one area, let the compound

work and move the object across the

piece across the wheel horizontally.

Never stop and hold the object against

wheel. Use very light pressure and

move down 1/4" after each pass until

finished

(FIG 12)

.

• On larger objects, divide the surface area into 1” x 2” areas and move from area to area.

APPLYING COMPOUND

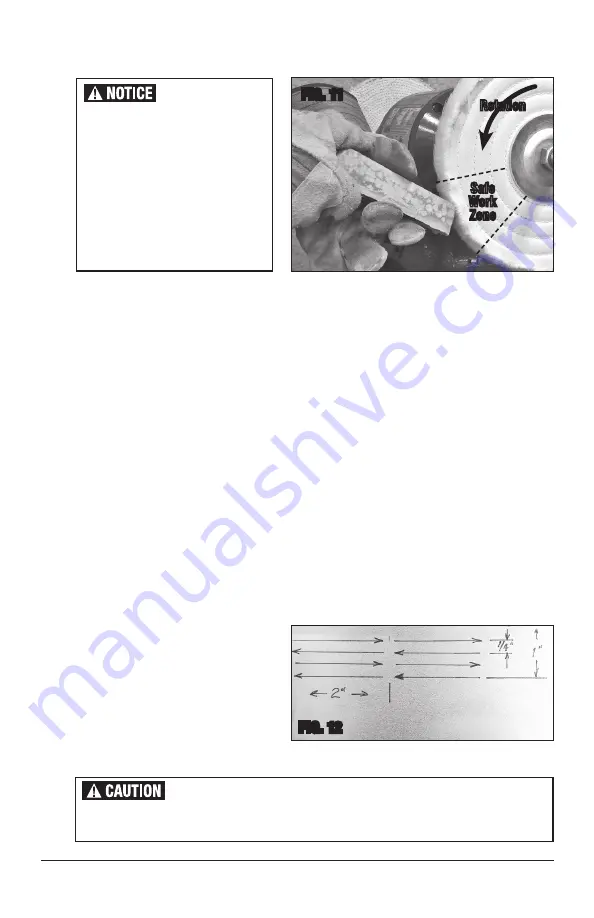

• Remove the Compound Bar from the package and holding it firmly, gently apply Compound

to the “Work Zone” area of the rotating wheel

(FIG 11)

. Apply sparingly, one or two seconds

against the wheel every few minutes is enough. More is not better, and it is best to apply a

small amount more frequently than too much at once.

FIG. 11

FIG. 12

Safe

Work

Zone

Rotation

The compound will appear to

be hard and dried out which is

quite normal. The compound is

formulated of specifically graded

abrasive in a hard-wax binder.

The heat generated by contact-

ing the rotating buff wheel melts

the binder and spreads the

abrasive on the wheel.

Never lose focus in keeping the edge of the object in the direction of wheel rotation

and in the “Work Zone” of the Wheel (Fig 13).