GUN SETTINGS

• Air Cap

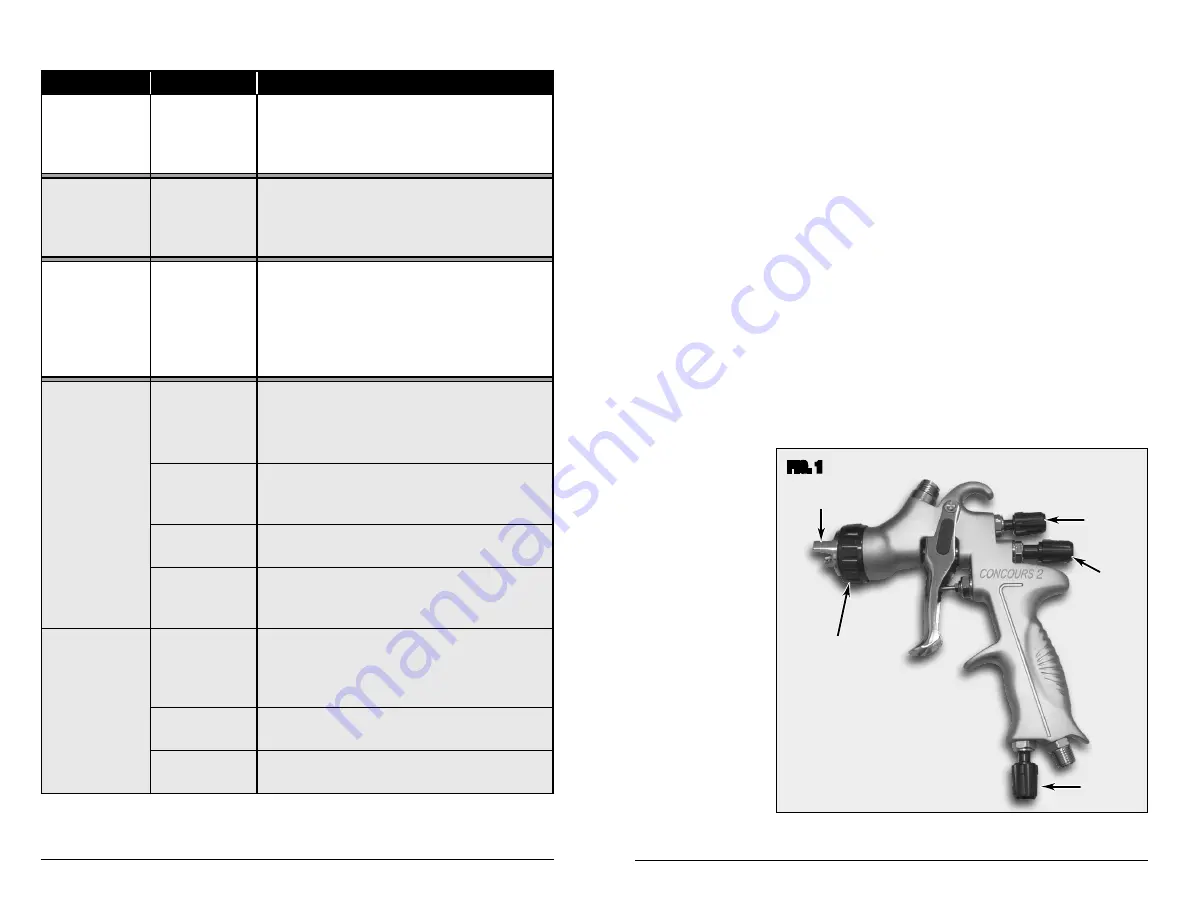

- Make sure the Air Cap is properly oriented in a horizontal plane to produce a vertical fan

spray pattern by viewing the HVLP Paint Gun from the front. To adjust, loosen Retaining Ring by

rotating counter-clockwise slightly, adjust Air Cap then re-tighten Retaining Ring

(Fig 1)

.

• Fluid Control

– The Fluid Control knob (located at mid-rear of gun body) regulates the distance

the Needle travels and the amount of paint flowing through the gun. Note: Generally for higher

viscosity coatings, a wider opening is desired while a closer opening is better suited for lower

viscosity fluids. To adjust, rotate the Fluid Control Knob outward (counter-clockwise as viewed

from the rear) to increase flow and turn inward to reduce flow

(Fig 1)

.

• Fan Control

– The Fan Control knob (located at the upper-rear of the paint gun body) controls

the size and shape of the spray pattern of “fan”. Rotating the knob counter-clockwise (as

viewed from the rear of the gun) will produce a larger and softer spray pattern while rotating it

clockwise will result in a smaller, sharper, round pattern. For most painting conditions, a larger,

softer fan is desired

(Fig 1)

.

• Air Control

– The Air Control knob (located at the bottom of the gun handle adjacent to the

air inlet) is opened by rotating in a counter-clockwise direction (as viewed from the bottom of

the gun). This is for “fine tuning” the airflow to the gun. You will generally want to set the inlet

pressure at the regulator, start with the Air Control in the full open position and decrease air as

needed

(Fig 1

).

• With practice,

you will quickly

acquire a “feel”

for the gun and

will be producing

professional

results.

• When you have

achieved your

optimal knob

settings, note their

positions with

the indicators on

the gun body and

knobs. This will

assist in quickly

“tuning” the gun in

future uses.

8

Eastwood Technical Assistance: 800.343.9353 >> techelp@eastwood.com

To order parts and supplies: 800.343.9353 >> eastwood.com

5

Fan

Control

Air Cap

✓

FIG. 1

✓

Air

Control

Retaining

Ring

Fluid

Control

✓

✓

✓

PROBLEM

CAUSE

CORRECTION

Gun produces

an uneven

spray pattern

or fan

Paint or film

buildup on Air

Cap blocking

air holes

Disconnect air supply and clean buildup from Air

Cap

Gun “spits”

or sputters;

discharges

large droplets

Paint or film

buildup on

Needle &

Nozzle

Disconnect air supply and clean buildup from

Needle & Nozzle. Note: Use of solvent may be

helpful, removal of the Nozzle may be necessary

Gun dispenses

only a small

amount of

paint or none

at all

Clump or piece

of paint film

blocking paint

inlet port

Disconnect air supply; remove paint cup, remove

blockage from paint inlet area then strain paint or

coating to remove clumps or film

Heavy textured

or “orange

peel” paint

appearance

Paint Gun is

too close to

surface

Keep within 8" to 12"

Inlet air

pressure too

low

Increase inlet air pressure and or decrease fluid

flow

Incorrect

thinner/reducer

Check paint manufacturer’s reducing/thinning

instructions

Incorrect

material mix

ratios

Check paint manufacturer’s mix ratio instructions

Excessive runs

and sags

Paint Gun

being moved

too slowly over

surface

Speed up gun motion over surface

Excessive fluid

flow

Decrease fluid flow by adjusting “fluid” knob

Paint mixed too

thin

Check paint manufacturer’s reducing/thinning

instructions

TROUBLESHOOTING