4

Eastwood Technical Assistance: 800.343.9353 >> techelp@eastwood.com

To order parts and supplies: 800.343.9353 >> eastwood.com

9

SET-UP

• Remove all components from carton, identify them and become familiar with their purpose.

• A 3/8" I.D.

minimum

air hose at a 25'

maximum

length is strongly recommended for

best results. Smaller I.D. hose and greater length may reduce available CFM and produce

unsatisfactory results.

• A clean, dry, regulated air supply is required. The use of an additional “on the gun” regulator is

strongly recommended to accurately control gun pressure while painting.

• Clean out the paint cup as well as the paint gun air and paint passages with a solvent such as

Eastwood PRE

or acetone to remove any residual manufacturing impurities before use. Dry

thoroughly.

IMPORTANT NOTES BEFORE PAINTING:

1. Please note that many variables affect the adjustment of a paint gun including paint

viscosity and type, atmospheric conditions such as humidity, barometric pressure and

temperature as well as air inlet pressure and operator preference. Always “tune” the

gun before each use as prevailing conditions may not be the same as the previous use.

2. It is always best to test spray on sheets of cardboard or masking paper with the actual

paint you will be applying while making your adjustments to become familiar with the

gun and achieve the ideal Fluid Control Setting.

3. Remember that a small amount of product used at this point can avoid

disappointment in your results and the need to re-do your work later.

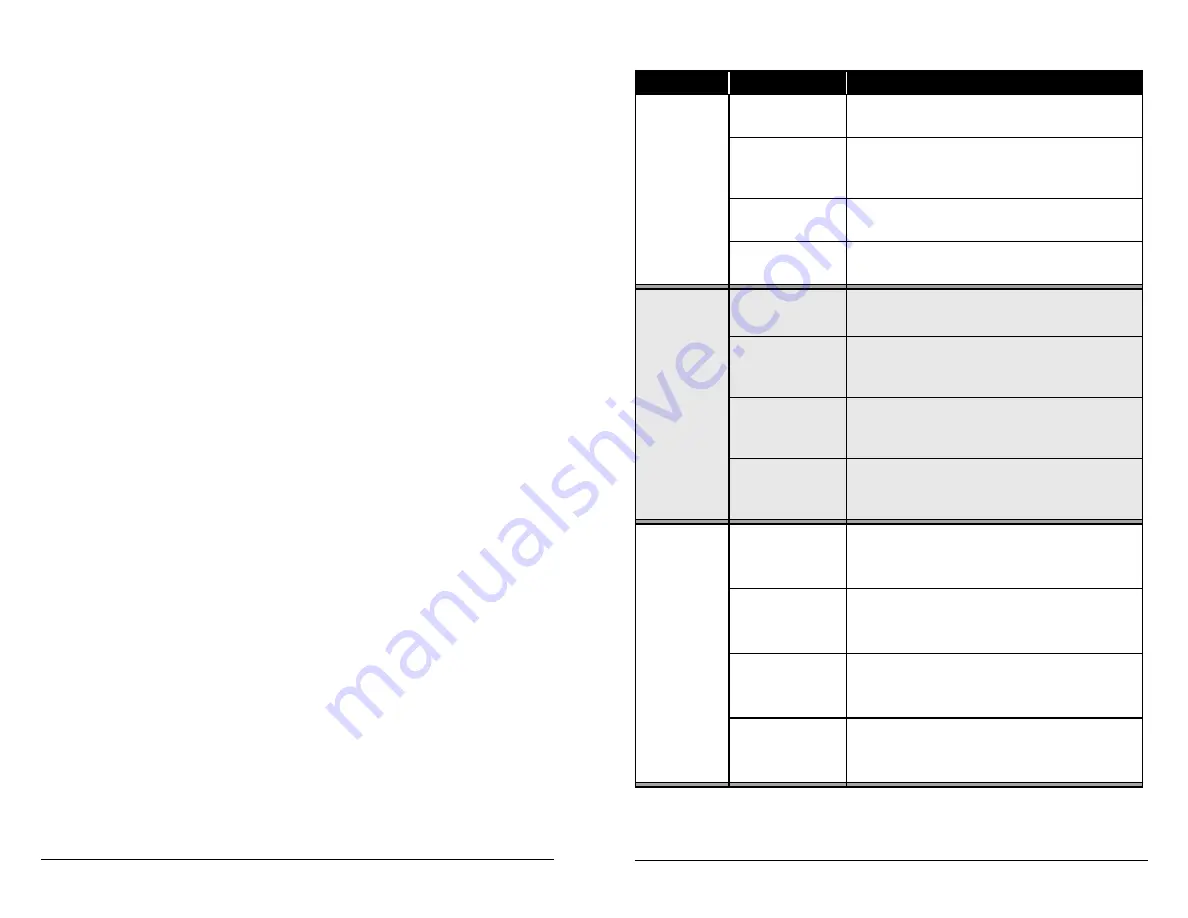

PROBLEM

CAUSE

CORRECTION

“Dry” paint

appearance

Paint Gun is too

far from surface

Keep within 8" to 12"

Paint Gun being

moved too fast

over surface

Slow down gun motion over surface

Inlet air pressure

too high

Decrease gun inlet air pressure and or increase

fluid flow

Incorrect thinner/

reducer

Check paint manufacturer’s reducing/thinning

instructions

Thin paint

appearance

Paint Gun is too

far from surface

Keep within 8” to 12”

Paint Gun being

moved too fast

over surface

Slow down gun motion over surface

Inlet air pressure

too high

Decrease gun inlet air pressure and or increase

fluid flow

Incorrect thinner/

reducer

Check paint manufacturer’s reducing/thinning

instructions

Paint

spray is

sputtering

Paint Gun is dirty

or contaminated

Disassemble and clean gun with suitable solvent

Nozzle or Air cap

loose.

Tighten Nozzle and or Air Cap

Needle tip or

Nozzle seat

damaged

Replace Needle/Nozzle set

Gun being tipped

too far down

Operate gun with tip tilted no more than 45º down

or up

TROUBLESHOOTING

(CONTINUED)