6

Eastwood Technical Assistance: 800.343.9353 >> tech@eastwood.com

FIG. 6

FIG. 6

FIG. 5

FIG. 5

SET UP

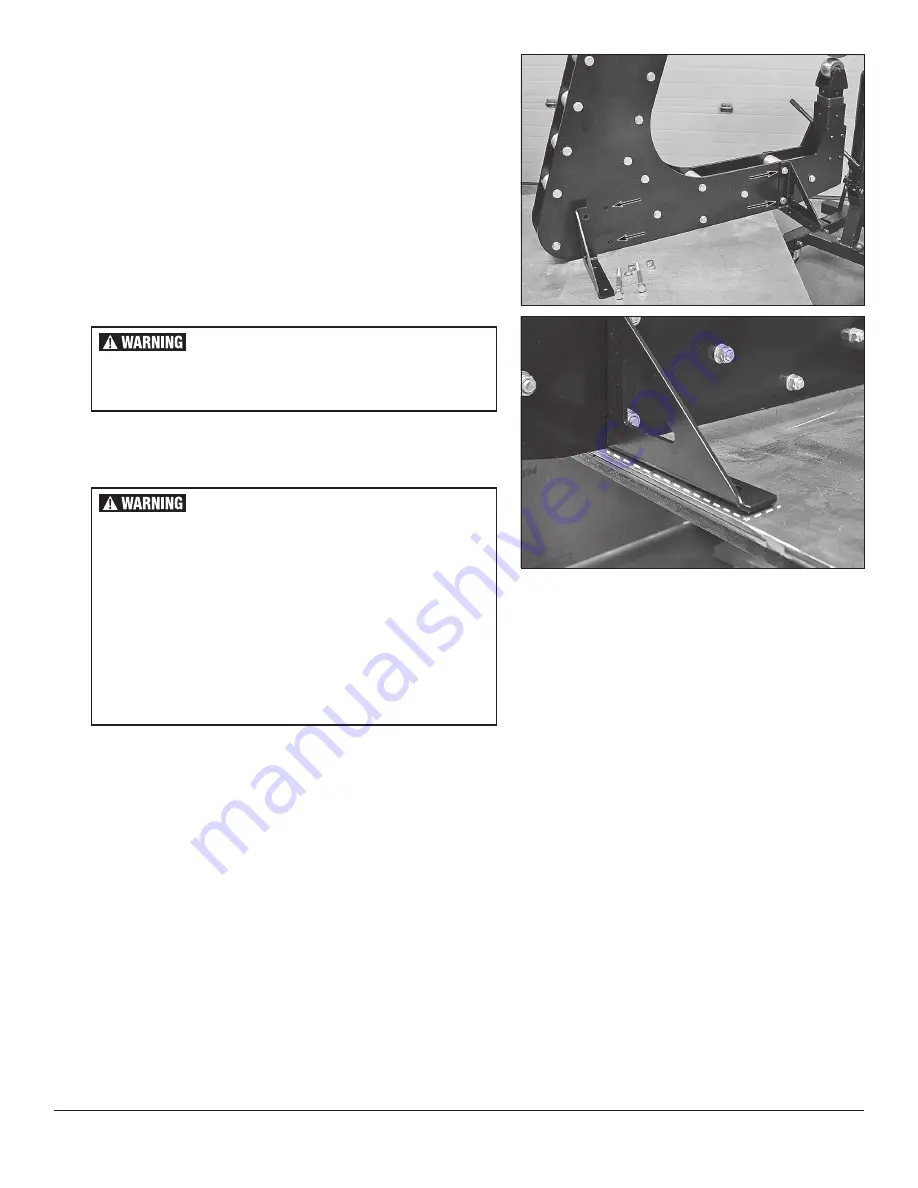

• With the English Wheel positioned on the mounting surface

(FIG 5)

, unbox the

Mounting Brackets.

NOTE:

There are two different Mounting Brackets supplied with the Eastwood

Elite Large Frame English Wheel. Refer to

FIG. 1

for recommended Bracket

positions.

• Remove the loose, preinstalled hardware in the bracket locations. Hold the

Mounting Brackets in place and slide the bolt through the brackets, then refasten

the nut and tighten to 40 foot-pounds (55 Nm)

(FIG 5)

.

• If mounting on a tabletop, bring the front of the mounting brackets flush with the

table edge

(FIG 6)

for the best wheeling experience and clearance of the Jack-

screw. If you wish to wheel with the anvils perpendicular to the frame frequently,

we recommend mounting it at a corner.

• To avoid possible personal injury or tool damage, it is required to mount the frame

securely to the work surface or frame before moving forward. 7/16” [12mm]

through bolts or lag screws with washers should be used.

ELECTRICAL SHOCK HAZARD!

When drilling a table ensure there are no electrical wires in the

path of the drill bit. Drilling into electrical wires could result in

severe injury or death.

•

Before beginning ANY work with the Eastwood Elite Large

Frame English Wheel, it is necessary that it be fastened to a

sturdy workbench anchored to the floor or wall.

•

Some minor physical force and awkward positions may be

applied to the workpiece while using The Eastwood Elite Large

Frame English Wheel. Failure to ensure proper footing can

quickly result in a fall which could inflict serious personal

injury or property damage. Always work in a clean, uncluttered

environment.

•

Make sure there is sufficient working room around the tool to

allow for safe handling of various sizes of metal.

✓

✓

✓

✓

Flush

Flush

with edge

with edge

Flush

Flush

with corner

with corner

(if mounting

(if mounting

at corner)

at corner)