10

Eastwood Technical Assistance: 800.544.5118 >> techelp@eastwood.com

ASSEMBLY

INSTALLING THE HANDLE

1.

Line up the holes in the handle with the holes

in the top in the welder.

2.

On each screw place an included lock

washer followed by a flat washer.

3.

Insert each screw through the handle and

into the top of the welder and tighten.

CONNECTING THE WELDER TO A POWER

SOURCE

The Eastwood Flux Core 90 welder requires a

dedicated 120 VAC, 20 Amp, 60 Hz grounded

outlet protected by a circuit breaker. Do not use

on power sources that have voltages less than

105 VAC or higher than 132 VAC. If using an

extension cord, use a minimum 12 AWG cord for

up to 25 feet.

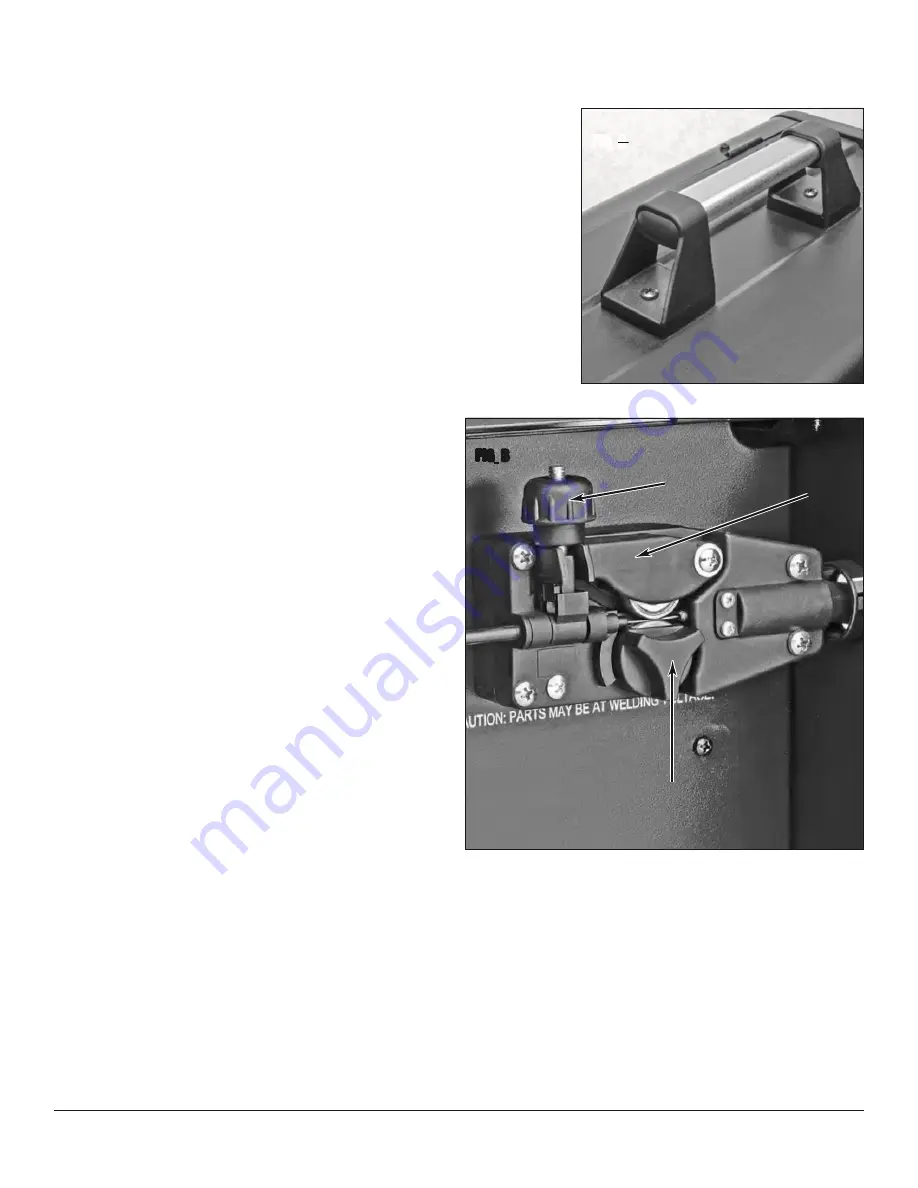

CHANGING THE DRIVE ROLLER

The Eastwood Flux Core 90 comes set up and

ready to use 0.030" (0.8mm) Flux-Core Wire. If

0.035" (0.9mm) wire is to be used, the drive roller

needs to be adjusted. Adjust the drive roller

according to the following procedure:

1.

Open the top door of the welder to access the

drive motor compartment.

2.

Lift the Pressure Adjuster

(FIG. B-B1)

out of

the way and move the Rocker Arm

(FIG. B-

B2)

away from the drive roller.

3.

Remove the Drive Roller Thumb Screw

(FIG.

B-B3)

by turning it counter clockwise and

pulling it away from the roller.

4.

Remove the Drive Roller and view the wire sizes stamped on each side of the roller.

5.

Install the Drive Roller in the orientation so that the size of the wire you are using is facing

you on the side of the drive roller.

6.

Reinstall the Drive Roller Thumb Screw

(FIG. B-B3)

.

7.

Put the Rocker Arm

(FIG. B-B2)

back in place and reset the Pressure Adjuster

(FIG. B-

B1)

.

FI

G

.

A

B1

FI

G

.

B

B2

B3