To order parts and supplies: 800.345.1178 >> eastwood.com

18

OVERLOAD PROTECTION

Your Eastwood Flux Core 90 Welder is equipped with an overload breaker

– this device will

protect your welder if the duty cycle is exceeded. If the output is exceeded, the internal breaker

will trip and stop power supply to the drive motor although the fan will still run to cool the unit. If

the breaker tripped resulting from an overload, the circuit breaker button under the side door of the

welder will extend out. This circuit breaker must be reset manually. Before resetting the circuit

breaker button allow the welder to cool for a minimum of 15 minutes.

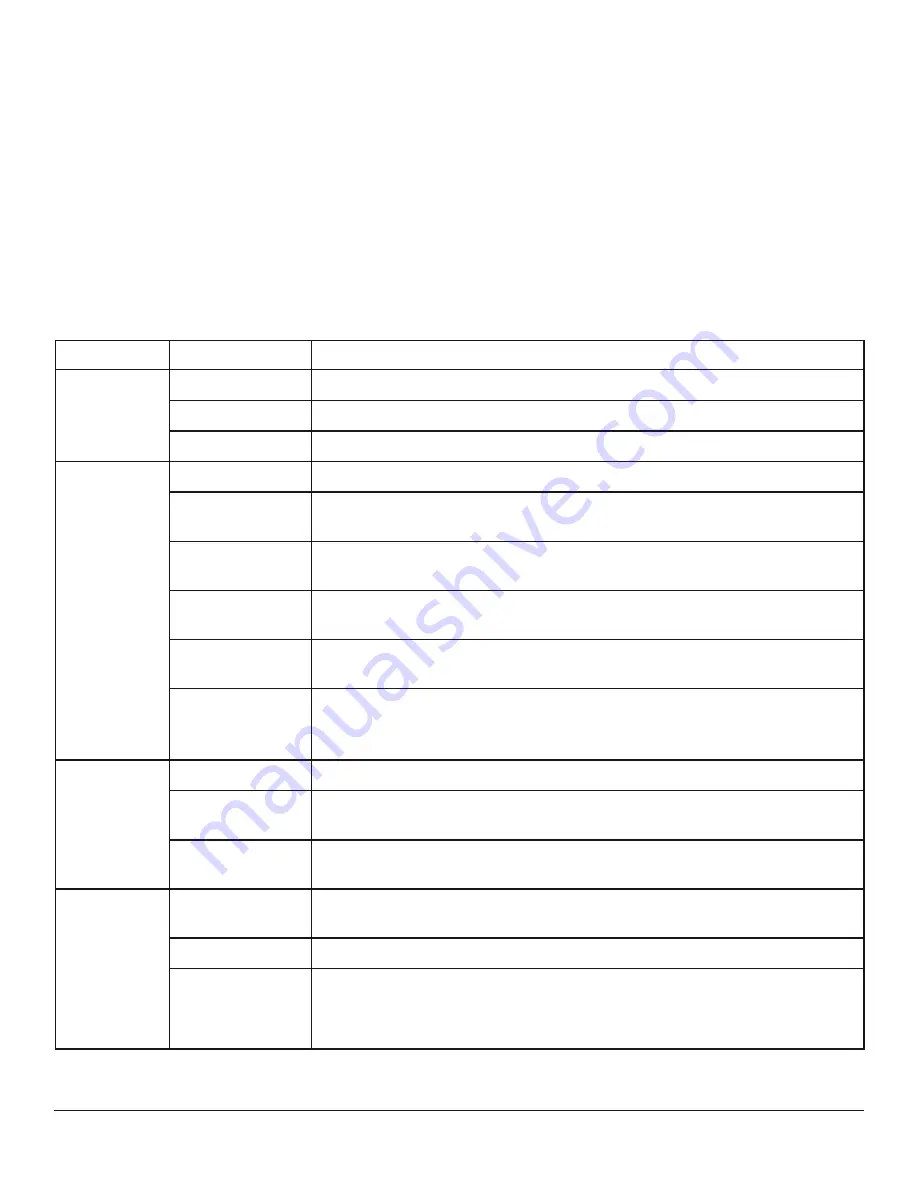

TROUBLESHOOTING

Problem

Cause

Fix

Burn

Through

High voltage

Adjust Voltage Output to low setting.

Fast wire speed Adjust Wire Speed to slower setting.

Slow Gun travel Increase your travel speed with the Welding Gun.

Lack of

Penetration

Low Voltage

Adjust Voltage Output to high setting.

Slow Wire

Speed

Adjust Wire Speed to higher setting.

Fast Gun

Travel

Decrease your travel speed with the Welding Gun.

Excessive Wire

Stick Out

Move the Contact Tip on the Welding Gun closer to the work piece

to shorten the length of exposed Welding Wire.

Material Too

Thick

The Flux Core 90 is rated for a max. thickness of 1/8"; exceeding

this will result in poor penetration.

Poor Material

Prep

If welding heavy gauge metals, it may be necessary to increase the

welding gap between the two pieces and also bevel the edges on

the weld side of the pieces.

Excessive

Penetration

High Voltage

Adjust Voltage Output to low setting.

Fast Wire

Speed

Adjust Wire Speed to slower setting.

Slow Gun

Travel

Increase your travel speed with the Welding Gun.

Warping

Lack of Tack

Welds

Tack weld the pieces in multiple areas to keep the pieces from

pulling apart.

No Clamping

Use Welding Clamps to secure the pieces in their proper shape.

Poor Technique

To prevent warping, allow the piece to cool after welding small

sections at a time. Move your welding areas around by not

completing all the welding in one section at once, rather welding a