Electrical Safety Tips

Electrical Safety Dos

• Make sure you, your work area, and your equipment are dry.

• If you are using an extension cord, make sure it is a grounded cord in sound

condition with no damage or frays, and of the correct wire gauge.

Electrical Safety Don’ts

• Never bypass the ground plug. Grounding is important for operation of the

unit and prevents shock.

•

Do not touch the emitter until after the activation switch is released and

the emitter has been touched to the ground clip to discharge the emitter.

• Once you are spraying the part with the powder, avoid touching the gun

to the part or other grounded objects.

• Do not step on, kink, or pull the wires. Before using the gun inspect

the condition of all wires.

• Do not touch or hold the part while coating.

Before you begin using the HotCoat™ Powder Coating System make sure

you have the following:

• An electric oven or toaster oven large enough to fit the parts you will be

coating. If you’ll occasionally be coating larger parts, you may want one of

our

Infrared Light Curing Systems (#10180 and #10680).

Do not use an

oven used for food preparation or located in a living area, as mildly toxic

fumes are given off by the powder during the curing process! Do not use

a gas oven!

Used ovens can be obtained very easily for little or no money by

checking your local newspaper classified section or by calling appliance

stores and remodelers in your area.

• An air supply source for the gun. A modest air compressor capable of at least

.5 cfm at 5-8 psi. You can even use a portable air tank with regulator. The air

supply must be dry and the use of a moisture trap is strongly recommended.

• A grounded 110-120VAC outlet or heavy-duty grounded extension cord

to plug in the 6’ power cord.

NOTE:

Unit must be grounded to work

properly and safely!

• A clean, safe, well-lit, well-ventilated work area.

• An activated charcoal respirator like our

Professional Respirator (#34229)

to wear while the coating is being cured.

• A dust mask like our

Dust Mask (#13000)

to wear while handling and applying powder.

• Disposable vinyl or

Nitrile gloves (#43098 M, L, XL)

to handle powder

and cleaned parts.

• A pair of

Goggles (#43090)

to provide eye protection during coating

and gun cleaning operations.

4

For technical assistance e-mail: techelp@eastwood.com

W

ARNINGS

R

EQUIRED

I

TEMS

Before You Begin

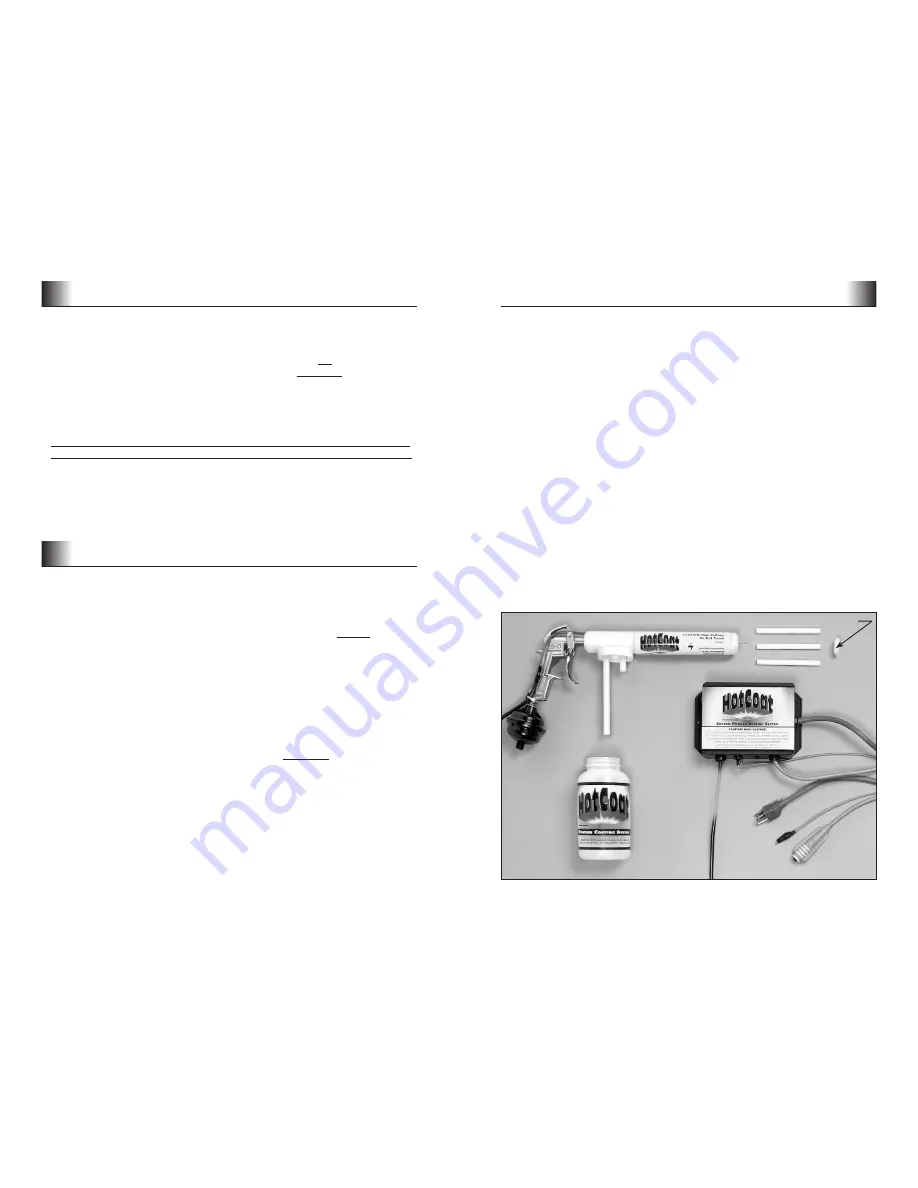

Remove all items from the box. Compare with list below to make sure unit is complete.

Contents:

Model 10198 HotCoat™ Powder Coating Gun:

applies a wide range of

specially formulated powder coatings.

#34066 Disposable Filter:

removes contaminants down to 1 micron from the

air supply. Designed to supplement existing moisture trap on your air supply.

Cup:

holds powder (fill 1-2 inches from bottom of cup)

Discharge Tube:

fluidizes powder

Pick Up Tube:

provides exit of fluidized powder to nozzle

Static Tubes (3):

induces static charge to powder

Deflector:

deflects powder pattern to assure even deposit

Complete HotCoat™

Power Supply unit with:

•A 6 ft. 120 volt, 15 amp electrical input cord

•A 6 ft. lead with ground clamp which is attached

to the part you are going to powder coat

•A remote activation switch with 6 ft. lead

•An 8 ft. high voltage gun power lead

Converts 110-120VAC to 9KVDC (no user-serviceable parts)

Activation Switch:

Applies voltage to Emitter: hold-on, release-off

Cup

Model 10198 HotCoat™ Powder Coating Gun

Deflector

#34066

Disposable

Filter

Discharge Tube

Complete HotCoat™

Power Supply Unit

with Leads

Pick Up

Tube

Activation Switch

110V AC

Power Cord

Ground Clip

Static Tubes (3)

To order parts and supplies, call 1-800-345-1178 or www.eastwood.com

5

D

ESCRIPTION

OF

P

RODUCT

P

ARTS