To order parts and supplies: 800.343.9353 >> eastwood.com

13

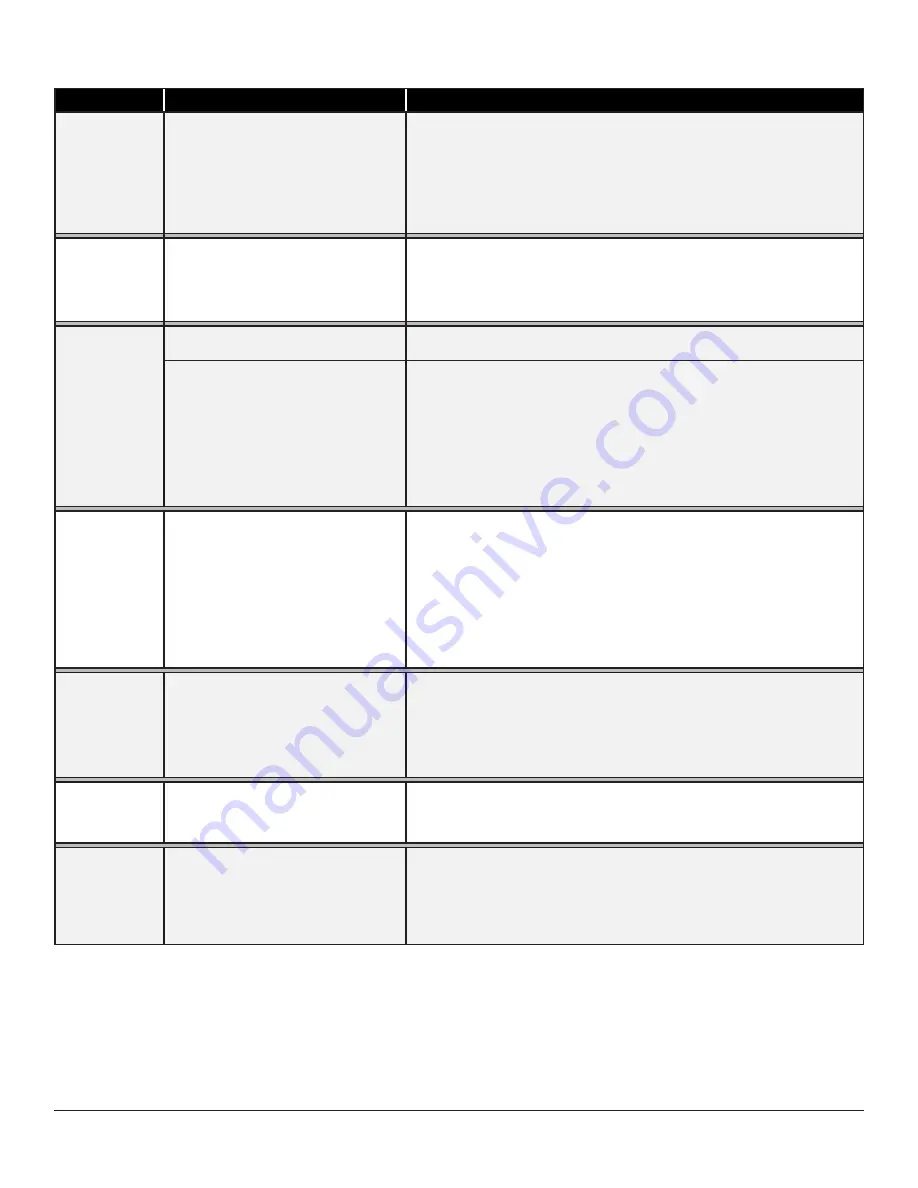

TROUBLESHOOTING

PROBLEM

CAUSE

CORRECTION

Oil/Water Mist

Spraying from

Under Pres-

sure Switch

The unit is collecting excess water in

the moisture filter #31716 and oil tank

which is raising oil level and resulting in

oil/water being forced into the white ny-

lon discharge hose going to the unloader

valve under the pressure switch.

Refer to

OIL TANK CONDENSATION DRAIN

for preventing condensation build up

by draining it regularly.

Unit Does Not

Turn On or Run

No power to unit or defective pressure

switch.

Check breaker is not tripped. If breaker is Ok – disconnect unit from power.

Check Continuity across switch terminals. A good switch will show continuity

across both sets of terminals, if one set of terminals is OPEN switch is bad.

Replace pressure switch #32207.

Motor Runs

Slow or Hard

to Start

Improper Supply Voltage/Circuit.

Assure unit has actual 208/240 on min 30-amp circuit and not 120VAC.

Defective start and/or run capacitor.

Disconnect unit from power.

• Remove Motor Electric Box Cover (on top of motor).

• Look at both capacitors for leaking oil, black soot, bloated or cracked cases.

• If defective- replace capacitors and motor controller.

Replace Start Capacitor #32213.

Replace Run Capacitor #32214.

Replace Motor Controller #32215.

Air Discharges

From Under

Pressure

Switch When

Unit Shuts Off

at 145 PSI

The Unloader Valve is located below the

Pressure Switch and is in place to relive

air pressure from the Scroll Pump and

Oil Tank. This discharge will last up to

20 seconds and is necessary to relive

air pressure in the Pump before next

cycle starts to eliminate starting against

a head pressure.

This is normal operation.

Overpressure

Relief Valve

Opens. Unit

Will Not Shut

Off.

Pressure Switch is stuck in “ON”

position- unit will continue to run even

if pressure switch knob is turned to

“OFF”. Unit will continue to vent through

Overpressure Relief Valve.

Replace Pressure switch #32207.

Motor Makes

Loud Metallic

Grinding Noise

Motor is defective from either bearing

failure, oil starvation or overheating.

Replace the following item:

Motor/Pump assembly #32208.

Squeaking/

Chatter Noise

at Air Filter

When Unit

Starts

Aluminum cylinder below air filter hous-

ing is the Intake Check valve. The valve

seal is making the noise.

It will not harm or hinder performance of unit and will cease after a few cycles.