To order parts and supplies: 800.343.9353 >> eastwood.com

7

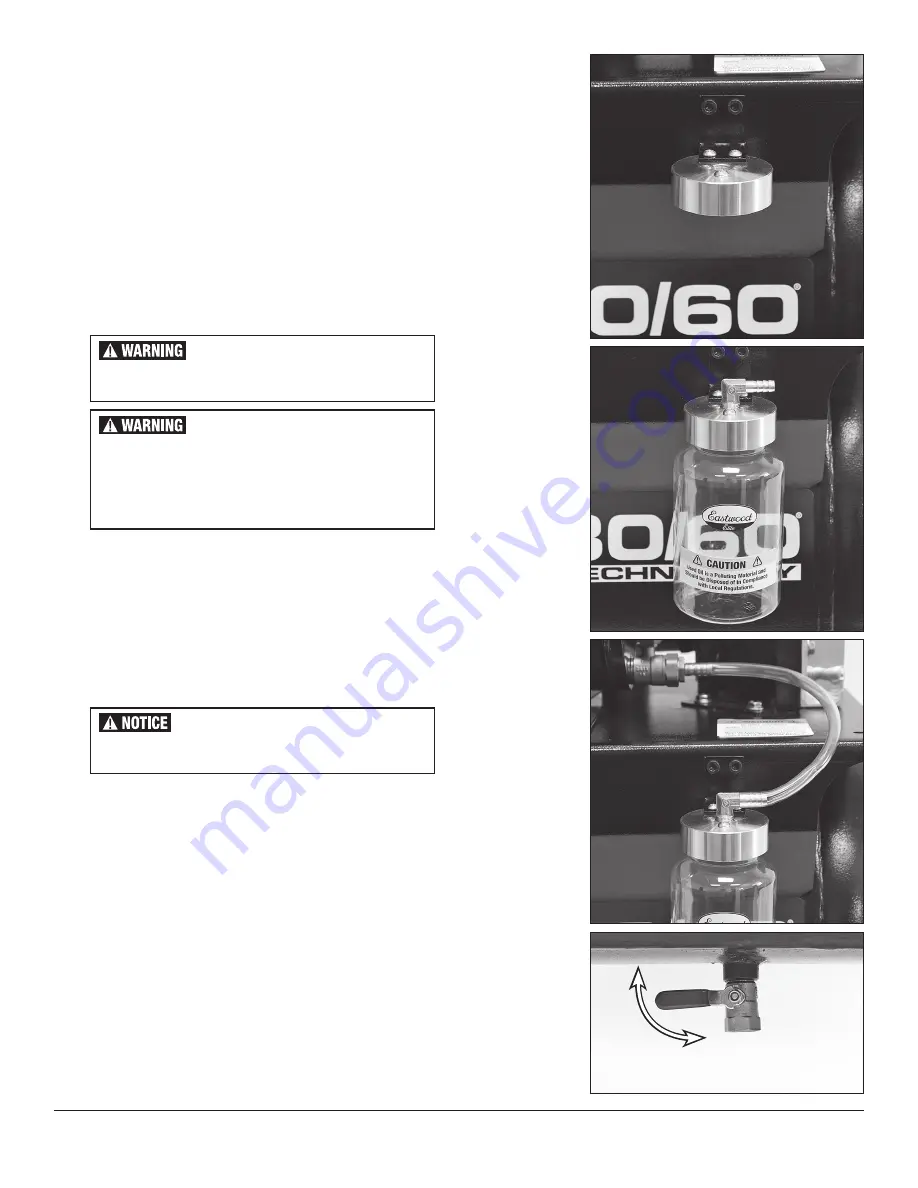

STEP 4 – MOISTURE DRAIN SYSTEM

The Moisture Drain System is specifically designed to provide enhanced moisture

extraction capability for operation in high humidity and extreme use environments.

Installation

• Use two M5 Phillips Head screws, Lock Washer, Washer and Nuts to secure

the Lid Assembly to the pre-installed Mounting Bracket

(FIG 9)

.

• Screw the Bottle into the Lid.

• Install the 90° Brass Barbed Fitting to the Lid by threading it into the tapped

hole in the center of the Lid

(FIG 10)

.

• Slip the oil drain hose over the Brass Barbed Fitting on the Moisture Drain

Lid, attaching it securely

(FIG 11)

.

FIG. 9

FIG. 9

FIG. 10

FIG. 10

FIG. 11

FIG. 11

FIG. 12

FIG. 12

BURN HAZARD!

The Scroll Pump generates heat during operation.

Use caution when servicing to avoid burns.

If any air or oil leaks are discovered, call Eastwood Tech

at: 1-800-343-9353 or email at tech@eastwood.com

INJURY HAZARD!

Before performing any service, turn Power Switch

to the “OFF” position (FIG 1). Shut off breaker or discon-

nect power supply. Release pressure from Tank (FIG 12)

until Gauge indicates 0 PSI. and allow to cool minimum

1 hour after last use before servicing to avoid burns.

CAUTION! Open Slowly!

Open

Close

STEP 5 – CHECK RUN PROCEDURE

• Close all outlet valves.

• Connect Compressor to power supply.

• Move the Power Switch to the “ON” position

(FIG 1)

.

• Allow the Compressor to run until it builds full pressure and

automatically shuts off (approx. 3 minutes)

• Move the Power Switch to the “OFF” position.

• Listen for any air leakage and observe the Scroll case, all lines and

fittings for any evidence of oil leakage.

• If no leaks exist, the Eastwood Elite QST 30/60 Compressor is now

ready for use.