10

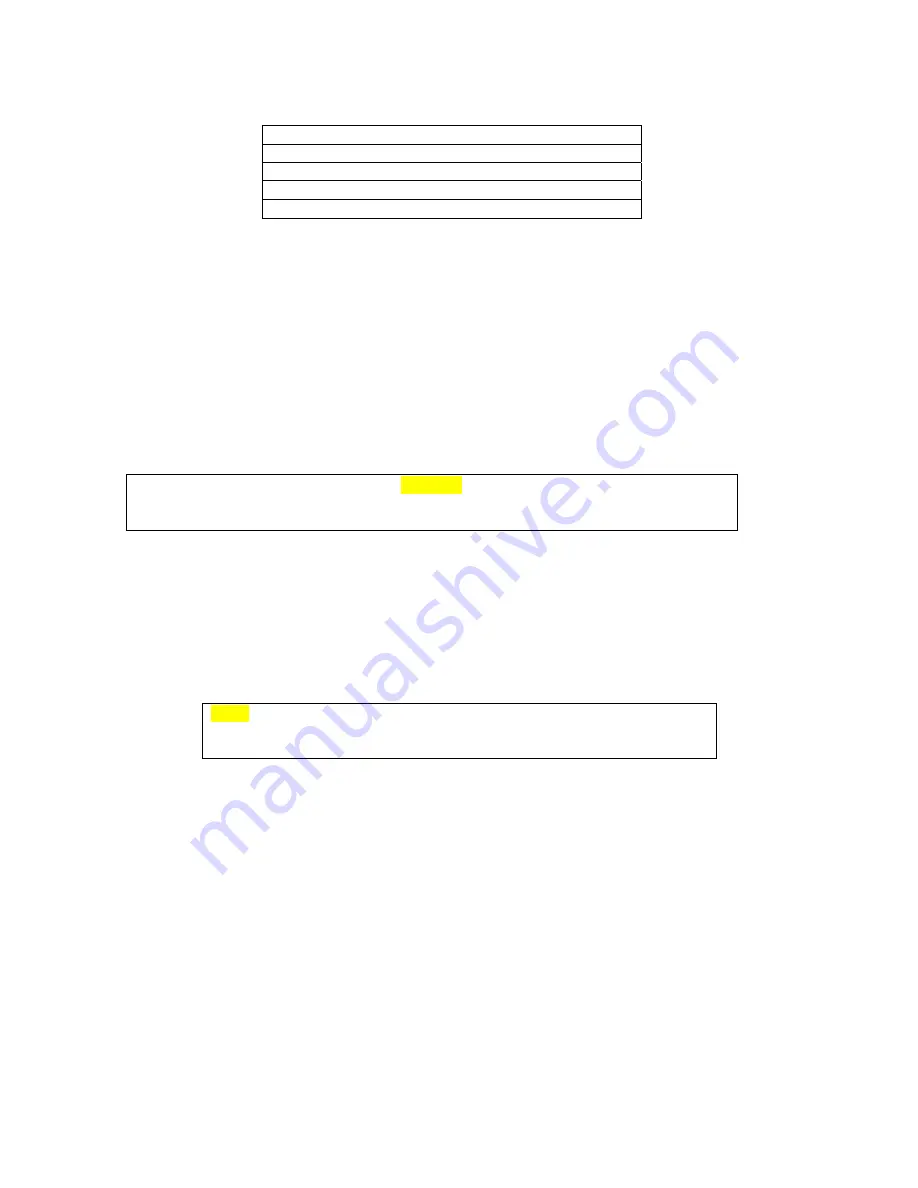

Material

Temperature Range

1.5 mil (.0015”)

300°F - 320°F

3 mil (.003”) 250°F - 265°F

Table 1

LAMINATING

1. Be sure the heaters have been turned on and are at the proper temperature. Be sure the film

has been properly threaded.

Caution:

Do not allow the temperature to exceed 350°F as this could cause the laminating film to

melt on the Heat Shoes and will void your warranty.

2. Adjust the Paper Guide on the Feed Table so that the right edge of the item will enter the

laminator at the desired position.

3. Press the Motor switch to the ON position. The film will begin moving through the laminator.

4. After clear laminating film exits the Pull Rollers at the rear of the machine you may slide the

first item to be laminated into the laminator with the right edge along the Paper Guide.

Note:

You may want to run a test lamination first as any item that passes

between the Heat Shoes will be laminated and cannot be recovered until it

exits the rear of the laminator.

5. Additional items may be fed in sequence, keeping enough distance between sheets for

trimming.

6. After the last item has exited the Pull Rollers, turn the Motor switch off.

7. Use the Zippy Cutter to cut across the film to remove the laminated items from the unit.

TROUBLESHOOTING

The following guide will assist you with most problems that may be encountered when laminating.

PROBLEM:

Laminator is inoperative. Motor does not turn, indicator

lights

are

out.

ACTION:

Unit may be unplugged. Connect power supply.