11

Display unit

Measurement

file handling

Save file

1. Select

and

to save your measurement.

2.

Enter a file name. The date and time will automatically be added to the file name.

The measurements that you save will be available to other users as well.

3. Press

to save the file.

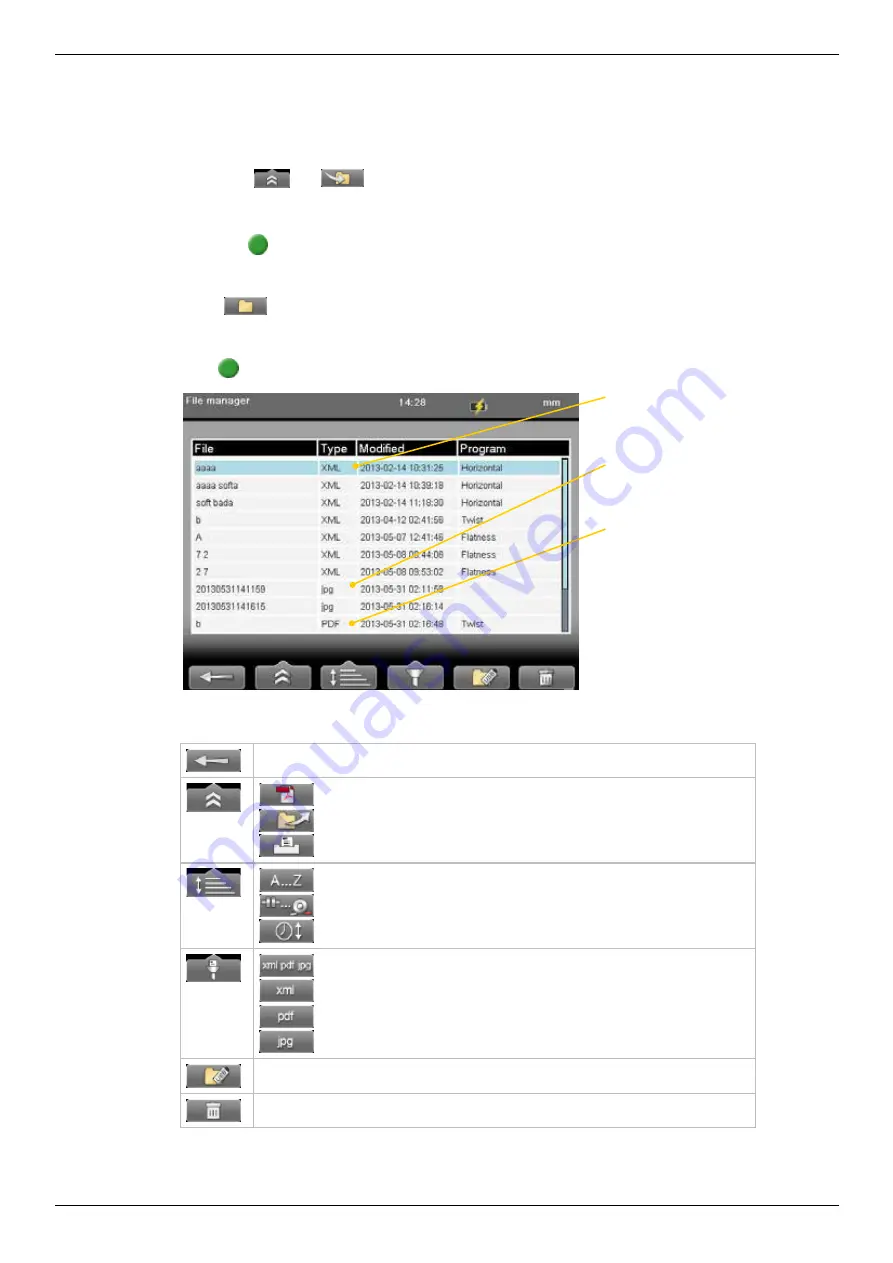

File manager

Select

(found on the start view and Control panel) to open saved measurements.

The File manager is displayed. Here you can easily when and from which program the

file was saved.

Press

to open a measurement file.

Function buttons

Back

to previous view.

13.

“Open file as template” on page 12

.

“Print file (Optional)” on page 13

Sort files alphabetically.

Sort files by measurement program.

Sort by time.

Show all files.

Show only xml files.

Show only pdf files.

Show only jpg files.

“Copy file to USB memory” on page 12

.

Delete files. Delete all

displayed

files or only selected file.

xml

A measurement file.

jpg

A report. The PDF report can not be

opened in the Display unit.

PDF is not available for E420.

Summary of Contents for E530

Page 1: ...MANUAL English 05 0560 Revision 5 0 System version 6 0 E530 ...

Page 2: ......

Page 26: ...22 ...

Page 28: ...24 ...

Page 48: ...44 Horizontal ...

Page 72: ...68 BTA ...

Page 84: ...80 ...

Page 86: ......