23

WARRANTY

ALL Easy Radiant Works heaters are covered by a 3-year guarantee. All heaters

manufactured by Easy Radiant Works are warranted to the original user against defects in

materials and workmanship under normal use for a period of 3 years from date of

purchase. Easy Radiant tubes are covered by a 20-year warranty against burn out. Any

part that is determined to be defective in material or workmanship during the warranty

period, and returned to Easy Radiant Works, shipping costs prepaid, will be, as the

exclusive remedy, repaired or replaced at the discretion of Easy Radiant Works. For

warranty claim procedures see “Prompt Disposition of Warranty Claims” below.

To the extent allowable under applicable law, Easy Radiant Works liability for

consequential or incidental damages is expressly disclaimed. Easy Radiant Works

liability in all events is limited to and shall not exceed the purchase price paid.

Many jurisdictions have codes and regulations governing sales, construction, installation,

and/or use of products for certain purposes, which may vary among jurisdictions. While

Easy Radiant Works attempts to assure that its products comply with these many codes, it

cannot guarantee compliance, or cannot be responsible for how the product is installed or

used. Before purchase or use of a product, review the product applications, and all

applicable national and local codes and regulations, and ensure that the product and

installation will comply with them.

PROMPT DISPOSITION OF WARRANTY CLAIMS

Easy Radiant Works will make a good faith effort for prompt correction or other

adjustment with respect to any product that proves to be defective in material or

workmanship within the warranty period. For any product believed to be defective under

this warranty, first write or call the dealer / retailer from whom the product was

purchased. The dealer / retailer will give further instructions. If unable to resolve

satisfactorily, write or call Easy Radiant Works at the address above giving dealer’s

name, address, date and number of dealer’s invoice, and describe the nature of the defect.

Title and risk of loss pass to buyer on delivery to common carrier. If product is damaged

in transit to you, file a claim with the carrier.

Summary of Contents for Middleman EZM-100-50

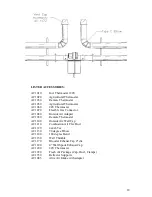

Page 17: ...17 VENTING OPTIONS...

Page 19: ...19...

Page 20: ...20...

Page 25: ...25 Middleman single stage wiring diagram...

Page 26: ...26 Middleman LTH dual input wiring diagram...

Page 28: ...28...