TWO SPEED CENTRIFUGAL • EX6750-2

Reliability You Can Count On!

© 2010 EasyPro, Inc

Pg. 4

MAINTENANCE

Lubrication

Motor - Permanently Lubricated ball bearings - no service required.

Rotary Seal - Requires no lubrication after assembly.

EASYPRO LIMITED WARRANTY

This product is warranted to the initial purchaser to be free of defects in materials and workmanship at the time of initial purchase and for a period of 18 months. In

the event this product malfunctions within 18 months from the date of purchase, the sole obligation of EasyPro, Incorporated (hereinafter referred to as EP) will be

to repair the unit or replace with an equivalent new or factory refurbished unit at EP’s discretion, subject to the following conditions:

1. You MUST call EP for a return authorization (RA#) number prior to returning, pumps returned without an RA# will be refused.

2. The malfunction is proved attributable to a defect in materials or workmanship, including repairs performed under this warranty. Malfunction for any other

reason — including but not limited to misuse, negligence, accident, tampering with parts, incorrect wiring, improper installation — will not be remedied

under this warranty.

3. EP specifi cally does not guarantee chemical compatibility, and expressly does not warrant units from any problems caused by chemical attack or failure due

to incompatibility of fl uid being pumped with pump materials of construction.

4. All warranty repairs must be performed by EP or an EP authorized company. Purchaser must retain the purchase receipt and present it with this certifi cate

as proof of ownership and entitlement to warranty repairs. Unauthorized repairs will not be compensated by EP, are not the responsibility of EP, and if such

repairs damage the product, such damages are not remedied under this warranty.

5. Purchaser shall bear all shipping, packing and insurance costs and all other costs, excluding labor and parts necessary to effectuate repairs under

this warranty.

6. Periodic check-ups are not covered by this warranty.

7. This warranty is in lieu of all other express warranties which now or hereafter might otherwise arise with respect to this product. Any and all limited warranties,

including the warranties of merchantability and fi tness for particular purpose, shall have no greater duration than the duration period of the express written

warranty applicable to this product, and shall terminate automatically the expiration of such duration period. Some states do not allow limitations on how

long an implied warranty lasts, so the above limitation may not apply to you. No action shall be brought for breach of any implied or express warranty after

one year subsequent to the expiration of the duration period of the express written warranty.

8. Incidental and consequential damages caused by malfunction, defect, or otherwise, and with respect to breach of any express or implied warranty, are

not the responsibility of EP, and, to the extent permitted by law, are hereby excluded both for property damage and, to the extent not unconscionable, for

personal injury damage. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you.

9. This warranty does not apply to any malfunction arising out of any application of this product other than normal use, unless such application is upon request

specifi cally approved in writing by EP.

10. The provisions of this warranty are severable and if any provision shall be deemed invalid, the remaining provisions shall remain in full force and effect.

11. Rights under this warranty are not assignable without the express prior consent in writing by EP and, regardless of the terms of such consent in writing, such

assignee shall have no greater rights than his assignor had against EP.

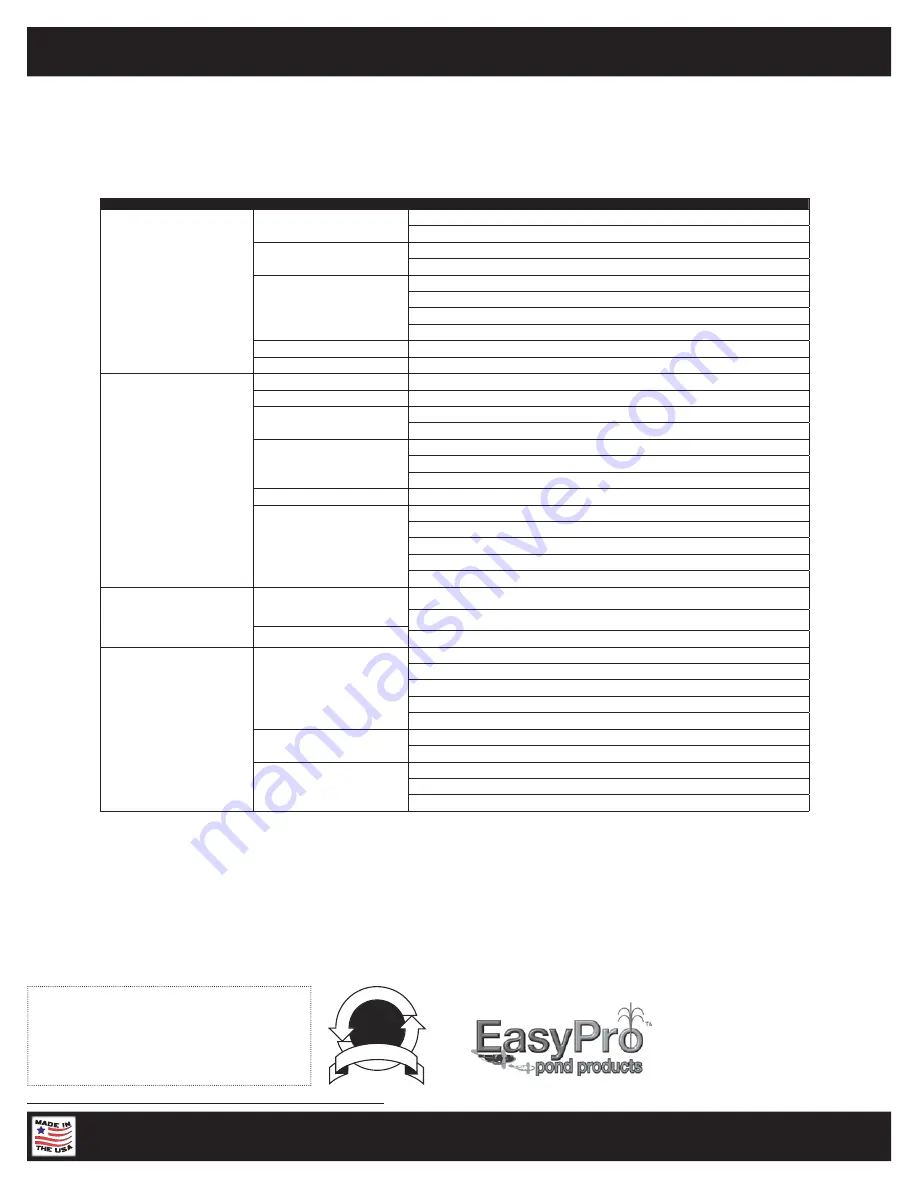

Symptom

Problem

Resolution

No Flow

Insuffi cient Prime

Prime system with water and purge all air from suction piping.

Install check valve.

Insuffi cient Power

Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Flow Restriction

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Verify check valve orientation and direction of permitted fl ow.

Clean out leaves or other debris from basket strainer (if applicable).

Air leak

Fix air leaks at fi ttings, connections, strainer basket etc. This typically occurs on the intake side.

System Incompatibility

Verify hydraulic compatibility: i.e. pump & pipe are sized for the system.

Low Flow

Air leak

Fix air leaks at fi ttings, connections, strainer basket etc. This typically occurs on the intake side.

System Incompatibility

Verify hydraulic compatibility: i.e. pump & pipe are sized for the system.

Insuffi cient Power

Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Flow Restriction

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Clean out leaves or other debris from basket strainer (if applicable).

Insuffi cient Prime

Prime system with water and purge all air from suction piping.

Cavitation

Verify airtight plumbing on the suction plumbing especially fi ttings!

Clean out leaves or other debris from basket strainer (if applicable).

Increase pipe size where possible.

Decrease suction pipe length, reduce the number of elbows, etc.

Verify hydraulic compatibility: i.e. pump and pipe are sized for the system.

Sporadic Operation

Insuffi cient Power

Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Poor Ventilation

Ensure adequate aifl ow over motor to prevent overheating.

Excessive Noise

Cavitation

Verify airtight plumbing on the suction plumbing especially fi ttings!

Clean out leaves or other debris from basket strainer (if applicable).

Increase pipe size where possible.

Decrease suction pipe length, reduce the number of elbows, etc.

Verify hydraulic compatibility: i.e. pump and pipe are sized for the system.

Insuffi cient Power

Verify power supply and connection from panel to pump.

Verify proper voltage. Some models are dual voltage (115/230).

Flow Restriction

Ensure valves are open.

Ensure plumbing is clear, including suction strainers, check valves, etc.

Verify check valve orientation and direction of permitted fl ow.

*The pump must be drained before servicing or if stored

below freezing temperatures. Periodic replacement of

seals may be required due to normal carbon wear.

EasyPro Pond Products

4385 East 110th, Grant, MI 49327

800-448-3873 • 231-834-5537 fax

www.EasyProPondProducts.com

Name: ________________________________________

Address: ______________________________________

City: _______________ State: _____ Zip: __________

Model: _______ Serial Number: __________________

Date purchased: ______Where purchased: ________

Gasgacinch

®

is a registered trademark of Porter Manufacturing. Noryl

®

is a registered trademark of the

General Electric Company. Tefl on

®

is a registered trademark of DuPont Company.

Activate your warranty by fi lling out this form and mailing to EasyPro Pond Products

18

18

M

on

th

W

a

r

ra

nty

5-10