EX8500 & EX11000

Reliability You Can Count On!

© 2019 EasyPro, Inc

Pg. 3

IN THE USA

ASSEMBLED

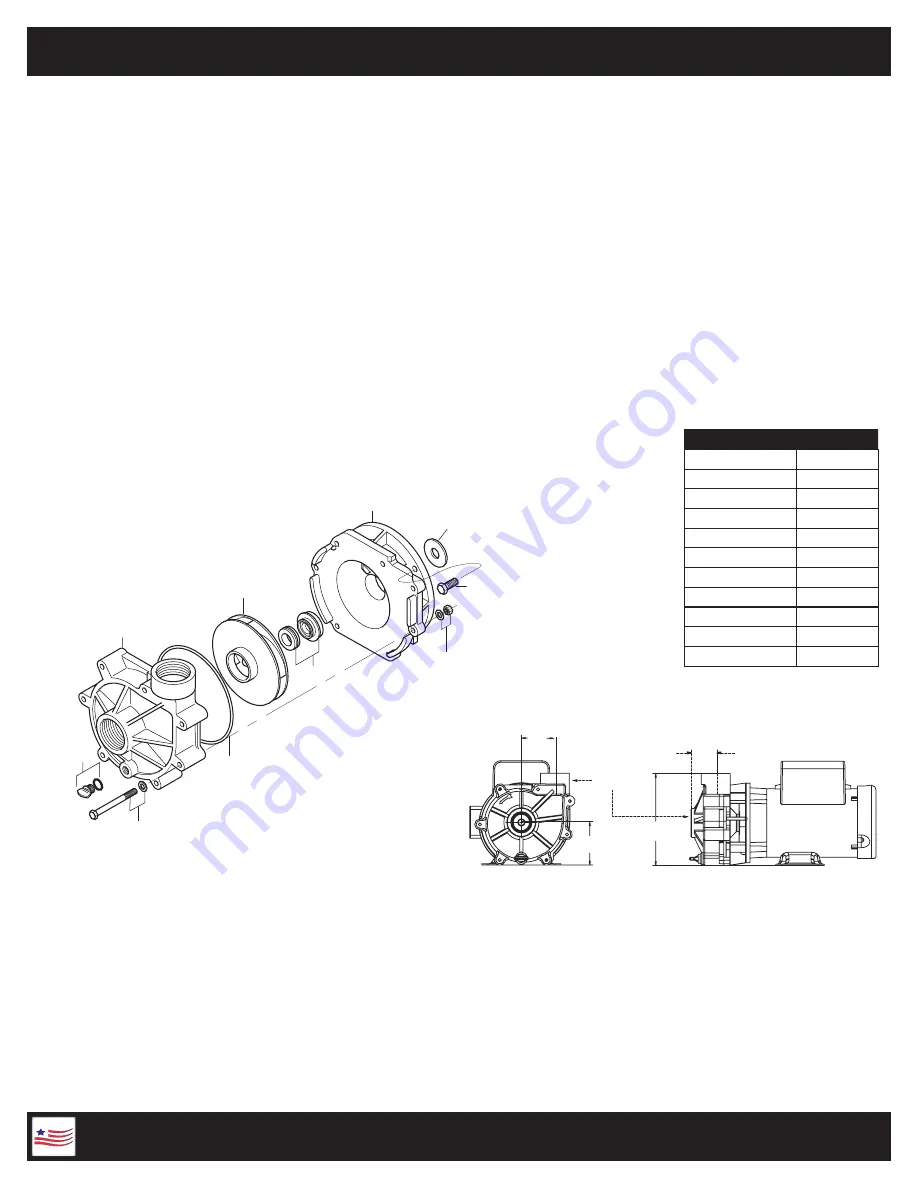

PUMP END ASSEMBLY

1. Clean and inspect all pump parts (0-ring, seal seats, motor shaft, etc.).

2. Apply sealant to the bracket bore ID wall and around the seal case - follow sealant mfg. instructions. We recommend using Gasgacinch

®

. Silicone

sealant can also be used.

3. Press carbon graphite seal into bracket while taking care not to damage carbon graphite face.

4. Place slinger (rubber washer) over motor shaft and mount bracket to motor.

5. Carefully, lubricate the seal seat elastomer OD and impeller hub ID with water. Press the seal seat into the impeller hub making certain that the

ceramic is in evenly - the sealing surface should be parallel with the impeller hub.

6. Carefully lubricate carbon-graphite and ceramic sealing surfaces with CLEAN water. Do not use silicon lubricants or grease!

7. Assemble bracket to motor with four M-bolts

8. Thread impeller onto shaft and tighten! If required, remove motor end-cap and use a screwdriver on the back of motor shaft to prevent shaft rotation

while tightening. Replace motor end cap.

9. Seat large O-ring in volute slot and assemble volute to bracket with seven 1/4-20 x 2

3

/

4

" hex cap screws, washers and nuts. Tighten in a cross

pattern (30 in-lbf).

10. Install drain plug with its O-ring in volute drain hole.

11. Before operating pump, allow a proper cure time for the sealant used in step 2.

DISASSEMBLY

1. Shut off power to motor before disconnecting any electrical wiring from the back of the motor.

2. Disassemble volute from bracket by removing the seven

1

/

4

" - 20 threads per inch x 2

3

/

4

" hex cap screws.

3. Remove cap covering shaft at back of motor and with a large screwdriver, prevent shaft rotation while unscrewing impeller.

4. Remove ceramic piece from impeller. (If you are replacing the seal)

5. Detach bracket from motor.

6. Remove carbon-graphite seal from bracket by pressing out from the back. Do not dig out from the front! (If you are replacing the seal)

DESCRIPTION

PART NUMBER

DRAIN PLUG

1000.110

O-RING, DRAIN PLUG

E014B70

VOLUTE

1000.070P

LARGE O-RING

1000.061

IMPELLER

1000.05__*

SEAL - BRASS

1000.0415

SEAL - SS316

1000.0414

SEAL-FOR POWER SERIES 1000.0411

BRACKET

1000.030P

SLINGER

1000.010V

HARDWARE KIT

1000.502

Note: These part numbers are only for stan

-

dard models within the EX8500 and EX11000

*1000.05__ Reference page one for Impeller

numbers.

VOLUTE

IMPELLER

WASHER &

LOCK NUT

BRACKET

M BOLT

LARGE

O-RING

SEAL

P-BOLT

& WASHER

DRAIN PLUG

& O-RING

SLINGER

2.75

3.50

7.54

2.00

Motor illustration is for reference only.

1

1

/

2

" FNPT