Service & Maintenance

See our website for a video about Mag Drive Pump Impeller

Replacement

1. Disconnect all power supplies before service.

2. It is highly recommended to place the pump in either an EasyPro skimmer or into an EasyPro

pump protector.

3. Clean the intake screen and foam filter when the flow is visibly reduced.

4. Clean the pump and impeller with clean fresh water.

5. When cleaning the pump and impeller, be careful not to loose the small plastic washers

positioned at the top and bottom of the impeller. These washers are critical to the quiet and

efficient operation of the pump.

6. Check inside the impeller housing for large debris or algae that could reduce the flow.

7. Clean the impeller housing using cotton swabs. Clean the outside of the impeller with a damp

cloth and clean water. A vinegar mixture may help remove hard deposits.

Operation of Pumps & Attachments

These versatile pumps have threaded inlets and outlets for connecting tubing. Fittings are included

to connect to a flexible tubing or PVC fittings can be used to connect to PVC pipe. Always be careful

not to overtighten fittings into the pump.

Mag Drive pumps can be used in a wide variety of water features or pond applications. Pumps may

be used in almost any position including on their side if used in basins or other tight spaces.

EP120 to EP1350 units include fountain nozzle sets and can be used as their own water feature.

EP400 to EP1350 nozzle sets include flow diverters that allow for operating the included nozzle with

the option to divert flow to another small water feature. Note: not all pumps come with all fountain

nozzles. See chart on following page for details.

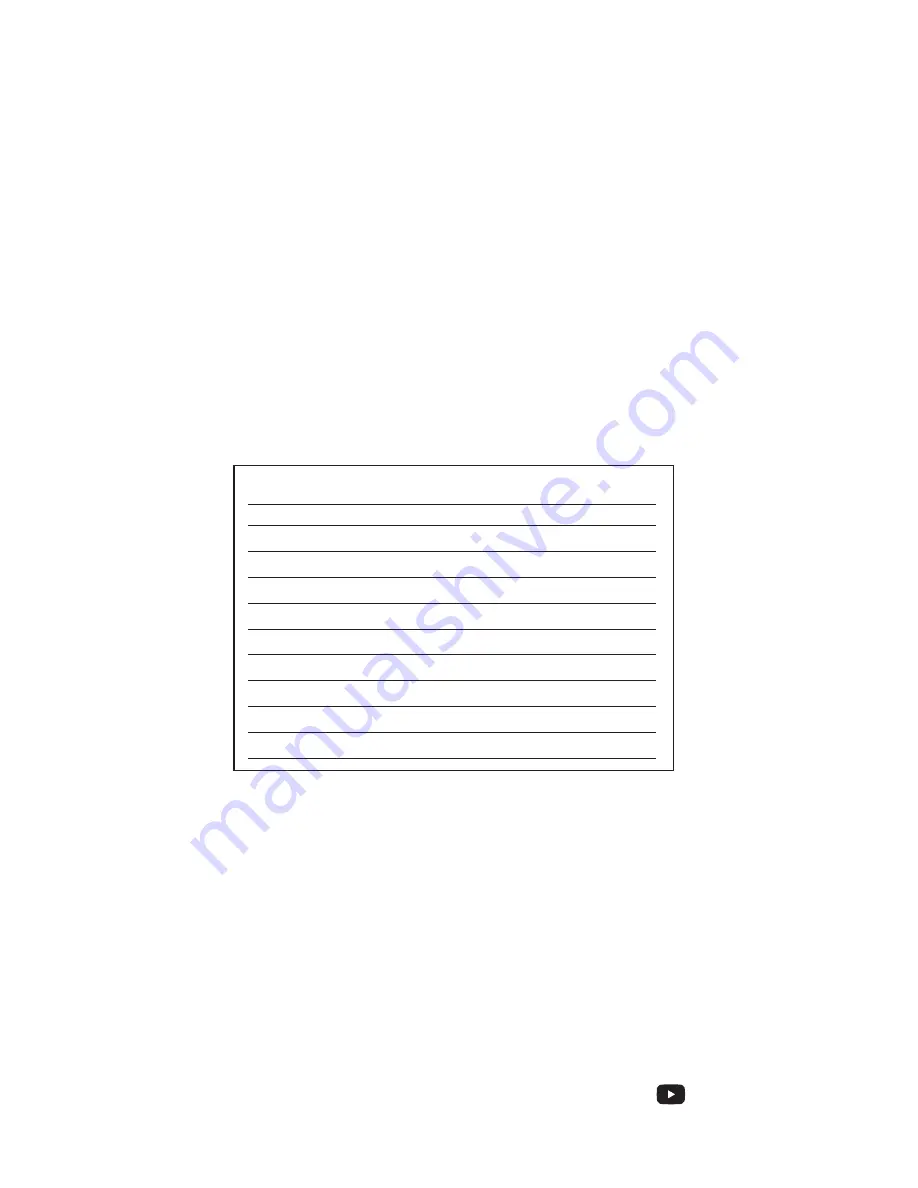

Part #

Foam Filter # Impeller Part #

EP120

EP120F EP120I

EP200

EP200F EP200I

EP400

EP400F EP400I

EP600

EP600F EP600I

EP850

EP850F EP850I

EP1050

EP1050F EP1050I

EP1350

EP1350F EP1350I

EP1750

N/A EP1750I

EP2200

N/A EP2200I

EP3200N

N/A EP3200IN

Replacement Parts for the EP120 — EP3200N Mag Drive Pumps

2

See our website for video of How to Replace an Impellar