1

2

7

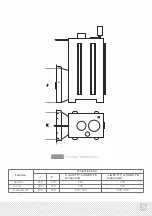

When installing the hot water production system, pay special attention to equipments'

location. The heat-exchange unit should be placed in such a way to minimize the distance to water

receiving tank and connect them in the most e ective and practic way possible.

Water receiving tank should be placed in such a way that tanks' bottom surface would be

not less than 100 mm higher than the top surface of the heat-exchage unit.

Maximum margin between the top surface of a heat-exchage unit and tanks' bottom

surface should be not more than 2 meteres. The water receiving tank is attached to the wall, in order

to do that there are fasteners on the back wall of the tank.

Systems are connected via metal pipes and pipe branches. Avoid sagging of the connecting

pipes, as they must be sloped from water receiving tank to heat-exchange unit.

Each additional bend of connecting pipes negatively a ect the process of circulation.

Connect water receiving tank and heat-exchange unit, avoiding unnecessary bends of

connecting pipes.

You should only use high-temperature materials (flax fiber) as a seal for threaded

connection joints of the heat-exchange unit.

To remove the steam from indoor space, connect the steam outlet joint to a pipe (hose)

which removes the steam.

Place one end of the pipe (hose) somewhere where coming out steam would be safe for people

around! When in use, watch carefully for the hose, so it doesn't have any bends!

For safe exploitation, tank should be covered with a wooden crate.

Pipes connecting the heat-exchange unit and water-receiving tank should be free to move in

places where they pass through the cover made of bricks or natural stones. The diameter of the

passage in the cover made of bricks or natural stones should be 5-10 mm larger than the pipes

coming out of the heat-exchange unit.

INSTALLATION OF HOT WATER

PRODUCTION SYSTEM